CASE STUDY: Predictive Maintenance with Retrofitted Electraulic Actuation

Electraulic Actuation is a brand of electro-hydraulic actuation unique to REXA. It combines the simplicity of electric operation, the power of hydraulics, the reliability of solid state electronics, and the flexibility of user-configured control.

#actuators #pressure-relief

Edited by Margo Ellis

Coke oven main pressure control is a critical control application for the safe operation of coke making. A plant’s actuator not only must position the crossover valve to achieve a pressure of 12 +/- 1 mmWC, but it also must avoid pressure spikes from volatile gases soon after coal charging, as shown here.

If the actuator is slow to respond, the collection main and coke oven gas pressure will increase and leak toxic gas at the oven doors. If the actuator overshoots, the coke oven pressure can decrease to a vacuum, entraining oxygen in air which ignites in the oven. Both pressure scenarios present major safety concerns. During normal operation, the crossover valve becomes coated in tar originating from the coke oven gases. Tar buildup increases the required torque to turn the valve. Left unchecked, this condition can potentially damage the valve, causing unnecessary downtime to repair. Regular cleaning ensures proper valve operation. Therefore, plant operators and technicians prefer to optimize the cleaning schedule.

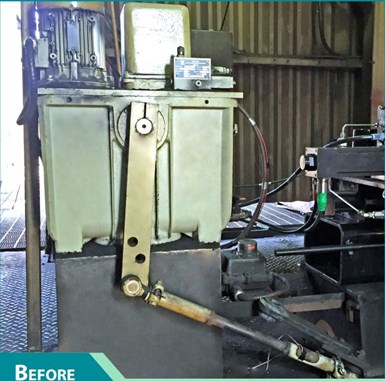

The preventative maintenance schedule for cleaning the crossover valve at a major integrated mill in Canada was based on fixed time intervals without any data related to its condition. The mill recently retrofit the existing valve with a REXA Rotary Electraulic actuator including the diagnostic capability to monitor operating pressure. The previous actuator’s oil reservoir was open to the environment, requiring frequent scheduled oil changes. The actuator also used a mechanical linkage to actuate the valve stem. These linkage assemblies introduce hysteresis, which can worsen over time and ultimately lead to poor control.

REXA consulted plant personnel and developed a solution that eliminated the need for mechanical linkage assemblies by mounting directly to the valve stem. With accuracy to 0.1% of desired position, less than 70mS deadtime, and zero overshoot, the collection main pressure control began operating better than ever before. The self-contained, positive pressure, non-vented Electraulic system never communicates with atmosphere, improving reliability and eliminating routine fluid maintenance.

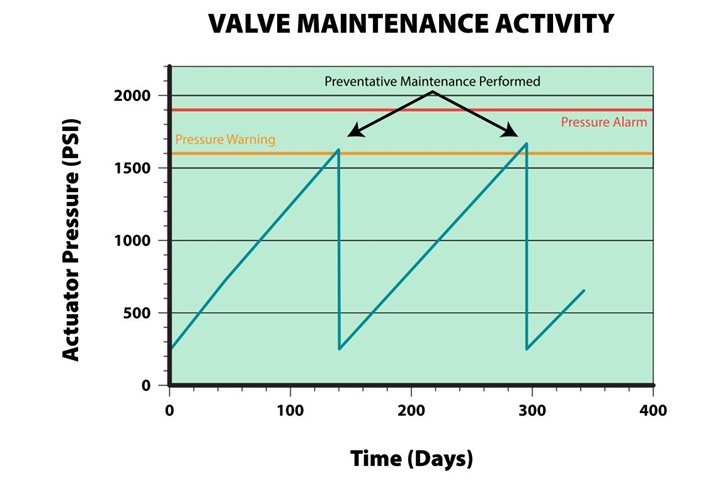

REXA’s Bluetooth graphical user interface tool displays the operating pressure and records it over time. User-configurable warning and alarm limits let the customer know when a pressure threshold is reached — signaling a need to initiate the valve preventative maintenance cleaning procedure. This ensures the maintenance group can schedule the crossover valve cleaning at an interval based on the valve’s health instead of an arbitrary time. Cleaning the valve only when necessary enabled a reduction in cleaning frequency, increasing uptime and personnel safety. Unscheduled shutdowns due to tar buildup on the crossover valve were eliminated.

RELATED CONTENT

-

Back to Basics: Pressure Relief Devices, Part 2

In Part 1 of Pressure Relief Devices, which appears in VALVE Magazine’s Winter 2016 issue, the author stresses the vital role pressure relief devices play in keeping end-user industries that deal with pressurized equipment safe.

-

The Dos and Don’ts of Isolating Pressure Relief Valves

Typically, isolation valves are used to block off a pressure safety valve (PSV) from system pressure, so that maintenance on the valve or related equipment can be conducted without a shut down.

-

What’s Your Temperature?

For decades, valve manufacturers have provided the maximum recommended working pressures and temperatures for their products, based on the materials used in the pressure-containing parts.

Unloading large gate valve.jpg;maxWidth=214)