Industry Capsules

Highlights of news affecting the industrial valve industry.

Acquisitions, Mergers & Partnerships

Flowserve to Terminate Agreement to Acquire Velan

French authorities have informed both Flowserve and Velan that they will not provide the requisite regulatory approval for the sale of Velan to Flowserve. The initial arrangement agreement made on February 9, 2023, and amended on March 27, 2023, will be vacated. Flowserve informed Velan of its intent to terminate the agreement based on the lack of regulatory approval from France for the transaction to close.

The closing of the arrangement was always pending regulatory approvals. To meet that condition, Flowserve offered a package of remedies and undertakings to the French authorities to help the deal close, but they were informed that they will not be provided with the regulatory approvals, regardless of these offers.

“We thank our employees and other stakeholders who supported the proposed transaction,” says James Mannebach, chair of the board of directors of Velan. “Although we are disappointed with the outcome and the decision of the French regulators, we remain confident in the future of Velan’s business. We will now turn our entire focus to the operation of a successful business while continuing to assess all strategic options available to the company to create value for all of our stakeholders.”

Flowserve president and CEO, Scott Rowe, says: “We are obviously disappointed with the French government’s decision. We do not believe the decision aligns with the French government’s stated goal of encouraging foreign investment into France’s economy. Throughout this process, Flowserve worked diligently and proactively to address all of the concerns that were raised by the French government. We were optimistic about the acquisition of Velan and the numerous benefits this would provide for both companies and their stakeholders. We sincerely appreciate the efforts of our Flowserve associates and Velan team members who worked so tirelessly on the transaction. We remain excited about the future of Flowserve and will continue to aggressively pursue our 3D strategy.”

The full statements and more information can be found on the Flowserve and Velan websites.

Emerson to Acquire Flexim

Emerson announced a definitive agreement to acquire Flexim Flexible Industriemeßtechnik GmbH (“Flexim”), a global leader in clamp-on ultrasonic flow measurement for liquids, gases and steam.

Headquartered in Berlin, Germany, Flexim brings complementary technology and strong customer relationships to Emerson, with an installed base of more than 100,000 flowmeters, as well as approximately 450 employees. Flexim provides clamp-on ultrasonic flow measurement technology for a broad range of end markets, including chemical, water and wastewater, life sciences, food and beverage and power generation. The transaction will expand Emerson’s automation portfolio and measurement capabilities, complementing its existing flow measurement positions in Coriolis, differential pressure, magmeter and vortex flow measurement. Upon the close of the transaction, Flexim’s Berlin headquarters is planned to become Emerson’s Ultrasonic Flow Measurement Center of Excellence.

Permian Resources to Acquire Earthstone Energy

Permian Resources Corporation and Earthstone Energy Inc. announced that they have entered into a definitive agreement where Permian Resources will acquire Earthstone in an all-stock transaction valued at approximately $4.5 billion, inclusive of Earthstone’s net debt. Under the terms of the transaction, each share of Earthstone common stock will be exchanged for a fixed ratio of 1.446 shares of Permian Resources’ common stock. The transaction strengthens Permian Resources’ position as a leading Delaware Basin independent E&P with over 400,000 Permian net acres, pro forma production of approximately 300,000 Boe/d1 and enhanced free cash flow profile to increase returns to shareholders.

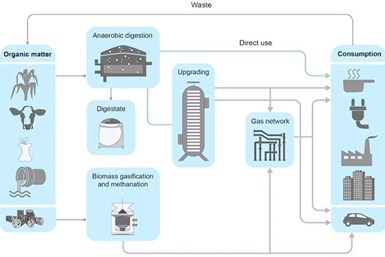

Groth Corporation's Biogas Business Line Acquired

Groth Corporation announced that Energenecs Inc. has purchased several product assets associated with the “Groth Biogas” business segment.

Groth Biogas, a business segment of Groth Corp. established over 60 years ago, provides pressure protection, control systems, flame control, liquid and foam separation, as well as fully integrated waste gas flare systems for the biogas and wastewater markets. Over the years, the business line has earned an excellent reputation by working closely with end users, engineering design firms and engineering contractors to deliver quality products and solutions to the market.

Since 2005, Groth Corporation has collaborated closely with Energenecs to provide a complete line of equipment for the effective and safe control of gas from anaerobic digesters, covered lagoons, landfill gas sites and agricultural and renewable natural gas (RNG) systems in Energenecs’ sales territory in the upper Midwest, resulting in a partnership yielding positive results for both companies.

Groth Corporation will continue to manufacture low-pressure relief products, emission control devices and flame protection products for oil and gas, chemical processing, pharmaceutical, food and beverage and other industries.

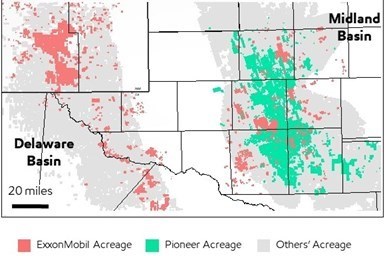

ExxonMobil to Acquire Pioneer Natural Resources in All-Stock Transaction

The merger combines Pioneer’s more than 850,000 net acres in the Midland Basin with ExxonMobil’s 570,000 net acres in the Delaware and Midland Basins, creating the industry’s leading high-quality, undeveloped U.S. unconventional inventory position.

Together, the companies will have an estimated 16 billion barrels of oil equivalent resource in the Permian. At close, ExxonMobil’s Permian production volume would more than double to 1.3 million barrels of oil equivalent per day (MOEBD), based on 2023 volumes, and is expected to increase to approximately two MOEBD in 2027. ExxonMobil believes the transaction represents an opportunity for even greater U.S. energy security by bringing the best technologies, operational excellence and financial capability to an important source of domestic supply, benefiting the American economy and its consumers.

“Pioneer is a clear leader in the Permian with a unique asset base and people with deep industry knowledge. The combined capabilities of our two companies will provide long-term value creation well in excess of what either company is capable of doing on a standalone basis,” says ExxonMobil Chairman and CEO Darren Woods.

Pioneer Chief Executive Officer Scott Sheffield commented, “The combination of ExxonMobil and Pioneer creates a diversified energy company with the largest footprint of high-return wells in the Permian Basin. As part of a global enterprise, Pioneer, our shareholders and our employees will be better positioned for long-term success through a size and scale that spans the globe and offers diversity through product and exposure to the full energy value chain.

Crane Engineering Awarded Distribution of ITT Engineered Valves in Five States

Crane Engineering, a leading distributor of fluid technology solutions in the midwest, announced today that it was awarded distributor partnership with ITT Engineered Valves for Dia-Flo, Cam-Line, Cam-Tite and exclusivity for the high-purity Pure-Flo product line. This expansion follows Crane Engineering’s previous and ongoing distribution of ITT Engineered Valves’ Fabri-Valve line.

The distribution region will span North Dakota, South Dakota, Minnesota, Wisconsin and the Upper Peninsula of Michigan, marking a significant shift in ITT’s channel strategy. The expansion of Crane Engineering’s partnership points to the company's sales growth, notably with product lines such as ITT Goulds Pumps.

"We are excited to continue our partnership with ITT Engineered Valves in a greater capacity. Ensuring our customers have access to top-tier product lines is paramount to us, and partnering with ITT exemplifies this commitment,” says Lance Crane, president and CEO of Crane Engineering.

Tellurian and Baker Hughes Announce Agreement for Driftwood LNG Equipment

Tellurian Inc. and Baker Hughes announced Wednesday an agreement to supply eight main refrigerant compression packages for Phase 1 of the Driftwood LNG project. The agreement secures a delivery schedule for the eight LM6000PF+ gas turbines, main refrigerant compressors, and control units required for Phase 1, supporting Driftwood’s ability to achieve initial liquefied natural gas (LNG) production in 2027.

Baker Hughes is also on schedule to complete fabrication of the electric-powered, zero-emissions Integrated Compressor Line (ICL) packages and other turbomachinery equipment for Driftwood Pipeline 200 by the end of next year, following the award in 2022.

“This agreement builds on the established collaboration between Baker Hughes and Tellurian as we continue to execute on our scope for the Driftwood Pipeline 200, which includes providing zero-emissions ICL compressor packages for their first deployment in North America,” says Lorenzo Simonelli, chairman and CEO of Baker Hughes. “Leveraging our 30 years of experience in LNG and broad portfolio of technologies for the natural gas value chain, we are pleased to support Tellurian also for the Driftwood liquefaction plant with our gas technology solutions.”

Up to $1.2 Billion Awarded in Direct Air Capture Projects

As part of President Biden’s Investing in America agenda, the U.S. Department of Energy (DOE) announced up to $1.2 billion to advance the development of two commercial-scale direct air capture facilities in Texas and Louisiana. These projects — the first of this scale in the U.S. — represent the initial selections from the President’s Bipartisan Infrastructure Law-Funded Regional Direct Air Capture (DAC) Hubs program, which aims to kickstart a nationwide network of large-scale carbon removal sites to address legacy carbon dioxide pollution and complement rapid emissions reductions. These emissions are already in the atmosphere, fueling climate change and extreme weather and jeopardizing public health and ecosystems across the globe. The Hubs are expected to ensure meaningful community and labor engagement and contribute to the President’s Justice40 Initiative. Together, these projects are expected to remove more than two million metric tons of carbon dioxide (CO2) emissions each year from the atmosphere — an amount equivalent to the annual emissions from roughly 445,000 gasoline-powered cars — and create 4,800 good-paying jobs in Texas and Louisiana.

This will be the world’s largest investment in engineered carbon removal in history and each Hub will eventually remove more than 250 times more carbon dioxide than the largest DAC facility currently operating. Their development will help inform future public and private sector investments and jumpstart a new industry critical to addressing the climate crisis on a global scale — highlighting a manufacturing boom that is delivering new economic opportunities, positioning America to be a global leader in the industries of the future, and accelerating efforts to meet the President’s goal of a net-zero economy by 2050.

Selected projects include:

- Project Cypress (Calcasieu Parish, LA): Battelle, in coordination with Climeworks Corp. and Heirloom Carbon Technologies, aims to capture more than one million metric tons of existing CO2 from the atmosphere each year and store it permanently deep underground. This hub intends to rely on Gulf Coast Sequestration for offtake and geologic storage of captured atmospheric CO2. The project is estimated to create approximately 2,300 jobs, with a goal to hire workers formerly employed by the fossil fuel industry for 10% of the overall workforce.

- South Texas DAC Hub (Kleberg County, TX): 1PointFive, a subsidiary of Occidental and its partners, Carbon Engineering Ltd. and Worley, seek to develop and demonstrate a DAC facility designed to remove up to one million metric tons of CO2 annually with an associated saline geologic CO2 storage site. The project is estimated to create approximately 2,500 jobs in construction, operations and maintenance, with existing agreements for local hiring.

New Service Screens and Ranks Sites for CCUS

SLB has launched a carbon storage screening and ranking solution that increases confidence in site selection decisions based on scientific analysis of the long-term integrity and economic potential of an asset.

The solution helps customers avoid suboptimal storage sites with risk factors that can waste valuable time and resources as well as decrease the probability of a carbon capture, utilization and storage (CCUS) project reaching final investment decision.

“CCUS is one of the most immediate opportunities to reduce emissions, but it must scale up by 100–200 times in less than three decades to have the expected impact on global net zero ambitions,” says Frederik Majkut, senior vice president of Carbon Solutions for SLB’s New Energy business. “Ensuring that a storage site is both safer and economical is crucial for the speed, scale and investment needed to meaningfully drive CCUS growth for a low carbon energy ecosystem.”

The screening and ranking solution uses both technical and nontechnical data to provide a detailed assessment of the capacity and economic viability of storage sites while identifying potential risks. A benchmark comparison, pulling from successful storage projects globally, is created to provide a relative basis for ranking each site.

The announcement was made as part of ADIPEC, an international platform uniting industry to accelerate urgent, collective and responsible action to decarbonize quicker and future-proof our energy system, that took place in Abu Dhabi in early October.

Westinghouse Establishes Center of Excellence for LEU+ in the US

Westinghouse announced the creation of a center of excellence for Low Enriched Uranium Plus (LEU+) fuel manufacturing at its Columbia Fuel Fabrication Facility (CFFF) in South Carolina.

The demand for LEU+ fuel in the range of 5–10% enrichment is expected to grow significantly in the coming years due to increased power generation which reduces the number of outages needed in nuclear plants. Westinghouse has initiated the work to expand its operations at CFFF with advanced processes, upgraded equipment and engineered safeguards for sustainable, efficient and reliable fabrication of LEU+ nuclear fuel.

“Westinghouse is committed to providing fuel products and engineering services required by our customers to achieve 24-month cycles through our High Energy Fuel Program,” says Tarik Choho, Westinghouse nuclear fuel president. “The program is aligned with our customers’ needs for LEU+ fuel. Further, this vision will provide high-tech job opportunities and increase collaboration with our local technical colleges and universities in South Carolina.”

New Ships to Offer Offshore Microreactors for Emergency Power

Global shipping and energy supply chain leader Crowley has teamed with BWX Technologies through a memorandum of understanding for a ship concept that has the potential to generate alternative, zero-carbon emission energy for defense and disaster needs by including a microreactor on board.

A new memorandum of understanding with BWXT’s Advanced Technologies subsidiary will allow both companies to jointly pursue and develop opportunities relative to the design, engineering and development of new shallow-draft hull ships that will supply small-scale nuclear energy to shoreside locations. The new ships would feature the latest technology available for factory-fabricated microreactors, readily deployed into a shipyard configuration for ease of installation on the vessel. The onboard power plant would supply energy to shore facilities, such as military bases in remote island locations, backup utility grids after disasters and provide power in other scenarios where traditional electricity sources are damaged or not possible.

The new vessel concept envisions a 378-foot ship that pulls from the logistics and marine capabilities of Crowley, a longtime operator with in-house vessel design by its Crowley Engineering Services, and the nuclear capabilities of BWXT, a leading supplier of nuclear components, fuel and services to the U.S. government at the highest levels of safety and security for more than 60 years.

This new vessel concept pairs traditional propulsion while carrying a modular reactor between 5 and 50 megawatts that can be activated upon arrival at the destination and be deactivated and transported after the power supply is discontinued. Buoyed power delivery cables will enable the ships to deploy energy connections to shore. Shallow draft hulls allow the vessels to maneuver to strategically deliver power for military activities or if disasters limit harbor access.

Industrial Data Labs Raises $1.5M in Seed Round

Industrial Data Labs, a Houston, Texas-based startup specializing in applied AI technology for the pipe, valve, fitting and flange (PVF) industry, is pleased to announce the successful closing of its seed round, securing $1.5 million in funding. This significant investment propels the company's mission to advance sales processes by leveraging AI to tackle the challenges encountered by inside sales teams.

Industrial Data Labs has rapidly gained recognition for its innovative approach to streamlining complex workflows in the industrial sales landscape. With the seed funding, the company is poised to deliver transformative solutions that enhance efficiency and create new opportunities for customers throughout the PVF industry.

Industrial Data Labs actively partners with prominent PVF distributors and manufacturers to co-create solutions that address specific pain points and generate meaningful results. By harnessing the power of AI within BOM and MRO workflows, the company aims to bring unprecedented efficiency, accuracy, and revenue potential to the industrial manufacturing and distribution sector.

People in the News

MSS Appoints New Leadership and Staff

The Board of Directors of the Manufacturers Standardization Society (MSS) of the Valve and Fittings Industry has named Lorna Soderberg as executive director. She previously served as MSS operations manager for more than three years.

Photo Credit: MSS

President of the MSS Board of Directors, Jim Barker, says: “Lorna has very effectively demonstrated her business and leadership skills in this position. She was instrumental in planning and executing a successful 2023 annual meeting, implemented a new AMS and website, and oversaw the sale of the MSS headquarters building.” Barker notes that he and the Board “are confident Lorna will do an excellent job leading and building on the foundation of MSS as we begin the next 100 years.”

“I have enormous respect for MSS and what the Society has accomplished since it was formed in 1924,” says Soderberg, “and I'm excited to lead the organization into an even more successful second century.”

Photo Credit: MSS

In addition, MSS has selected Stefania Adjei as technical coordinator. She comes to MSS with many years of project management experience. Adjei is pleased to join the MSS team to continue the excellent record of publishing new Standards and interacting with ISO as the US TAG 153 administrator.

The Manufacturers Standardization Society of the Valve and Fittings Industry, Inc. is a non-profit technical association organized for the development and improvement of industry, national and international codes and standards for valves, valve actuators, valve modifications, actuator mounting kits, pipe or tube fittings, flanges, pipe or tube hangers and supports, and associated seals, springs, spring washers and fasteners. MSS is an American National Standards Institute (ANSI)-accredited standards developer.

Unloading large gate valve.jpg;maxWidth=214)