The Future of Nuclear: Small Scale Nuclear Reactors?

The first nuclear power plant in the world was in Russia.

Here in the U.S. where the country’s current 100 nuclear reactors produce about 19% of the total electrical input, it would be especially difficult to replace that amount of power with solar plants or wind farms. There is, however, still much discussion about the “death of nuclear” especially after the closing of the San Onofre 2 and 3 near San Diego and Crystal River 3 in Florida because of expensive mechanical problems. There is speculation that the low cost of natural gas is behind the closing of Kewaunee in Wisconsin, which was running well, but losing money.

The economic feasibility of building and running large scale nuclear plants is no doubt of concern to the industry, but there are some new developments that may present a model for modern nuclear power development.

Nuclear for Small Communities

While small nuclear generators have been in existence for many years, powering submarines since 1954 and aircraft carriers since 1961, small scale nuclear has not been seriously pursued in the past for domestic use. Now, however, there are several projects in development. The new kids on the block are small scale, nimble and promise to be much more cost effective than the behemoths that have been built in the past.

Instead of multi-billion dollar projects taking decades, these new modular plants could potentially provide safe, reliable power for isolated areas or smaller communities within a couple of years. They could be the answer for those communities that simply don’t require huge amounts of power but also cannot be supported by hydropower or natural gas, or renewables like solar and wind.

Many of these communities currently depend on trucking in expensive fossil fuels like diesel to operate generators. In communities like Kimmirut in Nunavut, Canada, a kilowatt hour costs $1, compared to 8.5 cents per kWh in big cities. Since the reactors are still in pre-development, it’s not certain that small scale nuclear can reduce the expense of providing power to communities like this, but they do offer an intriguing possibility, and several U.S. companies have been developing the technology.

If a small scale nuclear plant can safely work there, certainly there must be many other potential uses in the U.S. and around the world.

Small Scale Nuclear Defined

The International Atomic Energy Agency (IAEA) defines “small” as producing less than 300 MWe and the term “SMR” is generally used as an acronym for Small Modular Reactors. Whether they are built independently or as modules in a larger complex with capacity added incrementally as required, they are generally of a simpler design than current large reactors.

The small size is important; as the whole idea is that they can be produced in a factory and shipped to a site. This means that the site can be prepared ahead of time, while the reactor itself is being constructed offsite, and with a much smaller footprint than that which has been required in the past.

The small modular systems are also designed with passive safety systems, meaning that there is no requirement for emergency AC power to maintain core cooling, and there are no closed cooling water systems required. They will not require proximity to water, making them a viable choice for land-locked locales.

Small Scale and the DOE

A number of production reactors for weapons plutonium and tritium were built and run by the Department of Energy (DOE) from 1953 to 1991 at the Savannah River nuclear site in Georgia. Covering more than 310 square miles (800 km2) its major focus now is cleaning up after work done the United States’ nuclear buildup. The Savannah River National Laboratory is housed there, and while no reactors are operating there at this time, there are a number of options being considered for the site in the future. One of those options is working with small scale reactor developers and in March 2012, the DOE signed agreements with companies interested in constructing demonstration SMRs at its Savannah River site.

Jim Giusti at the DOE’s Office of External Affairs advised VALVE Magazine that there are currently memos of understanding with three modular reactor companies to develop reactors when funding becomes available or if they would like to use the Savannah River site. While none are being built or planned for at the Savannah River site at this time, Giusti said that the DOE does have the technology that can help them, and there is land on which projects could be situated if these companies pursue that avenue of development.

The three companies and reactors are: Gen4Energy (formerly Hyperion) with a 25 MWe fast reactor, Holtec with a 140 MWe PWR, and NuScale with 45 MWe PWR. The DOE is discussing similar arrangements with other SMR developers, to provide land but not finance.

A Sampling of Small Scale Reactor Technology

NuScale

NuScale’s design is based on MASLWR (Multi-Application Small Light Water Reactor) developed at Oregon State University in the early 2000s.

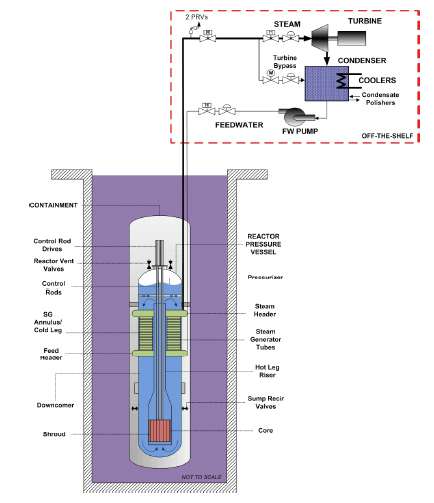

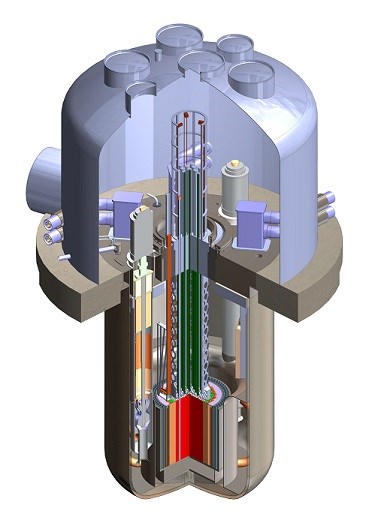

Each NuScale power module consists of a fully integrated reactor vessel, pressurizer, steam generator and containment vessel, and is accompanied by a companion turbine that generates an output of >45 MWe. Each module is self-contained, operating independently of the other modules in a multi-module configuration. However, all modules are managed from a single control room.

A single facility could have from 1 to 12 NuScale Power Modules. In a multi-module plant, one unit can be taken out of service without affecting the operation of the others and each module is capable of operating on a multi-year refueling cycle, but is limited to operate on a 24-month cycle by NRC requirements for inspection intervals.

In October 2011, Fluor Corporation paid over $30 million for 55% of NuScale. The DOE sees this as a "near-term LWR design."

Gen4 (Hyperion) Power Module

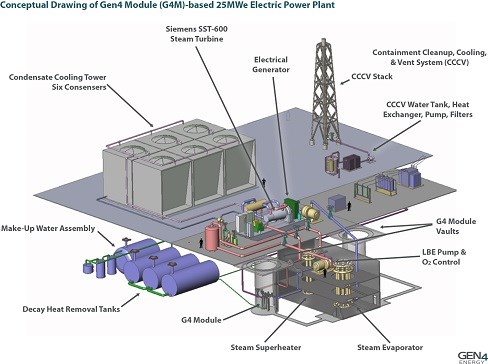

The Gen4 Module is a 70 MWt/25 MWe lead-bismuth cooled reactor concept using 20% enriched uranium nitride fuel with a planned 10-year lifetime, without refueling.

The company has said it plans to build a prototype by 2015, possibly with uranium oxide fuel if the nitride is not then available.

In March 2012 Hyperion Power Generation changed its name to Gen4 Energy and the name of its reactor to Gen4 Module (G4M).

mPower

Babcock & Wilcox (B&W) is developing its mPower reactor, a 500 MWt, 150 MWe integral PWR designed to be factory-made and railed to sites. In November 2012 the DOE announced it would support accelerated development of the design for early deployment, with up to $226 million. B&W draws upon over 50 years experience in manufacturing nuclear propulsion systems for the U.S. Navy.

The mPower reactor is also modular. Each unit is factory-made and several units would be combined into a power station of any size, but most likely 500-750 MWe and using 250 MWe turbine generators (also shipped as complete modules), constructed in three years.

Other systems include the Westinghouse SMR and TerraPower’s traveling wave reactor (TWR).

In Part Two of this article to be published in Web Features this summer, we’ll examine opportunities for valve, actuator and control manufacturers in the small nuclear reactor environment.

Kate Kunkel is Senior Editor of VALVE Magazine and Web Editor of VALVEMagazine.com. Reach her at kkunkel@vma.org

RELATED CONTENT

-

Valves in Space

All of these valves need to be built to precise fits and finishes and to stringent performance requirements because “On a spacecraft, everything has got to work. If it breaks, you’re done.”

-

The Basics of Eccentric Plug Valves

Wastewater systems present many challenges to pumps and valves because the flow can contain grit, solids and debris, depending where in the process the equipment is located.

-

Testing of Hydrogen Valves

Valves are used to control all types of fluids, and while some are easy to manage, others can be a challenge. At the top of the challenging list sits hydrogen, the smallest, lightest molecule known to man.

Unloading large gate valve.jpg;maxWidth=214)