ADDITIVE MANUFACTURING

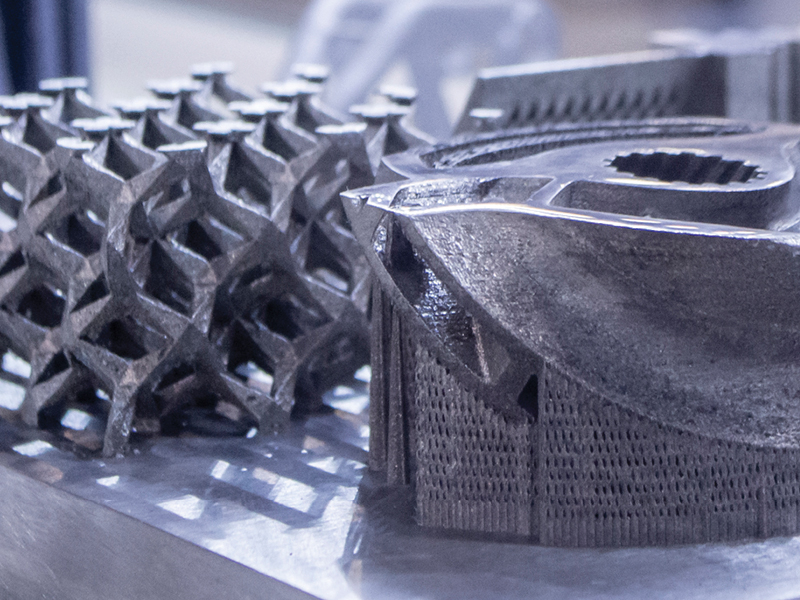

Metal and polymer additive manufacturing/3D printing is increasingly being used to make new design prototypes and production parts as well as jigs, fixtures and other devices used in a machine shop.

Narrow by Additive Manufacturing Product Category

FAQ: Additive Manufacturing

What is additive manufacturing?

“Additive manufacturing” (AM) describes the use of 3D printing to make functional components, including tools and end-use production parts. Unlike “subtractive manufacturing” processes such as machining, where parts are created by removing material, additive manufacturing builds geometries by “adding” feedstock such as filament, wire or powder. Depending on the 3D printing process and application, additive manufacturing can utilize a growing catalog of materials including metal alloys, thermoplastics, thermoset polymers and composites.

What is subtractive manufacturing?

“Additive manufacturing” (AM) describes the use of 3D printing to make functional components, including tools and end-use production parts. Unlike “subtractive manufacturing” processes such as machining, where parts are created by removing material, additive manufacturing builds geometries by “adding” feedstock such as filament, wire or powder.

Is additive manufacturing the same as 3D printing?

Some say yes and we say no! AM and 3D printing are overlapping terms but not synonyms. 3D printing is the operation at the heart of additive manufacturing, just as “turning” or “molding” might be the operation at the heart of a conventional manufacturing process. In a nutshell, 3D printing is one step in an overall additive manufacturing workflow that also includes design, build preparation, postprocessing, business considerations and more. Importantly, “3D printing” does not describe just one type of technology. Per ISO/ASTM, there are seven different “families” of 3D printing processes, and a growing number of material and machine options.

What is 3D printing?

“3D printing” describes an entire group of part making processes that generally build components layer by layer. ISO/ASTM recognizes seven distinct types of additive manufacturing technology:

- Vat photopolymerization – a vat of photopolymer resin is selectively cured through point-by-point or layer-by-layer exposure to light

- Powder bed fusion (PBF) – powdered metal or polymer is fused together using an energy source, typically a laser or electron beam

- Binder jetting – a binding agent deposited onto powdered metal or sand creates the geometry; in the case of metal, binding is typically followed by sintering to fuse the powder

- Material jetting – droplets of material are precisely deposited to build a geometry

- Sheet lamination – sheets of material are stacked and laminated together through ultrasonic welding, brazing, adhesives or chemical means

- Material extrusion – a material such as polymer filament or pellets is heated and extruded through a nozzle

- Directed energy deposition (DED) – metal powder or wire is fed into a meltpool created by a laser or electron beam in a process similar to welding

Get Listed!

Thousands of people visit this Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.