MATERIALS

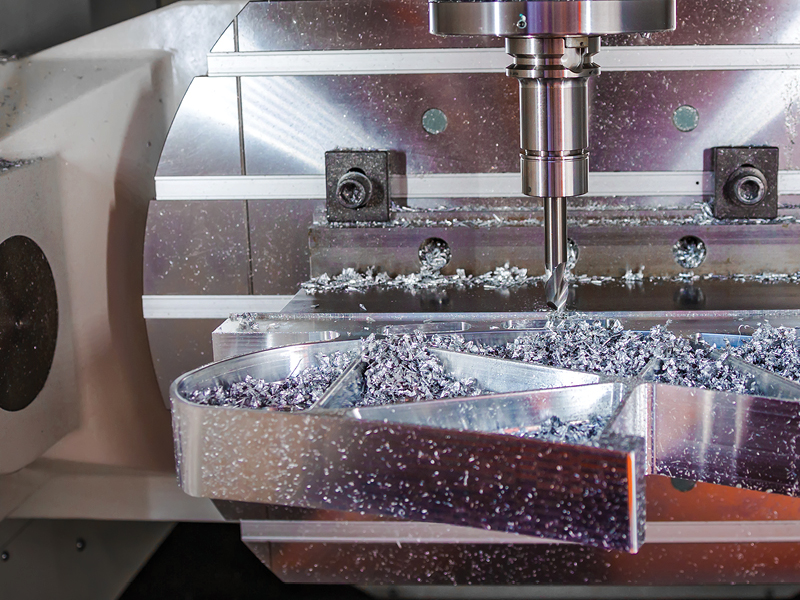

Production machine shops often must source various types of material including aluminum, brass, steel, stainless steel, titanium, high-temperature alloys and plastics in bar, blank or plate forms.

Narrow by Materials Product Category

FAQ: Materials

What stainless is easiest to machine?

303 stainless steel performs well at conventional cutting speeds and feeds but also can shine at high speed in high temperature cutting conditions. It is common for manufacturers to add a small percentage of sulfur to 304 stainless to make the more machinable 303 stainless.

(Source: Making Stainless More Machinable)

How do I straighten bar stock for a bar feeder?

Bar stock is held in place by feed rollers and a set of guide bushings as material is removed by cutting tools in the rotating wheelhead. For coiled stock up to 6 mm in diameter, a straightening unit must be used to straighten the incoming material before it is fed into the rollers and guide bushings. After passing through the straightener, the material is clamped between a set of grooved rollers, which rotate to feed the material into the cutting zone. The grooves can be round for wire or contoured to match profiled stock. By locating the rollers close to the guide bushing, small diameter wire can be machined without bending or whipping.

(Source: A Lathe That Doesn’t Turn The Workpiece)

Get Listed!

Thousands of people visit this Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.