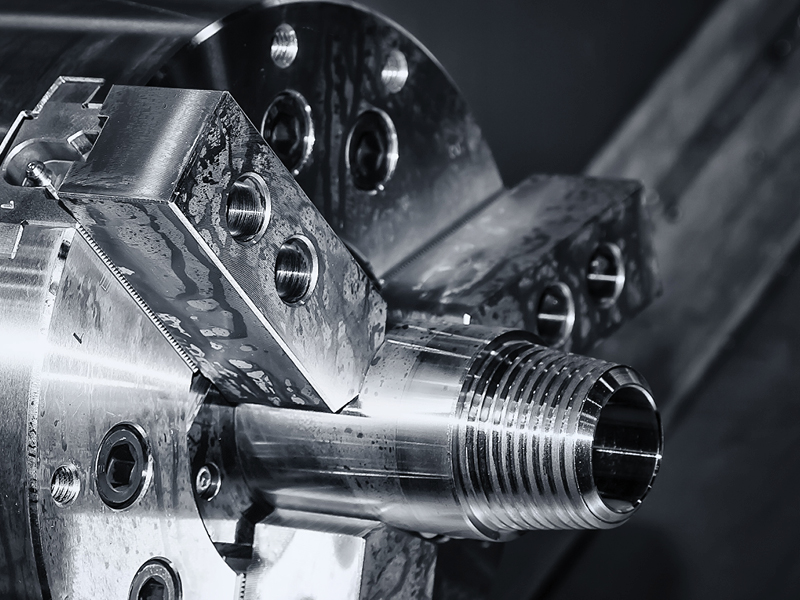

WORKHOLDING & HANDLING

Workholding devices such as collets, chucks, live centers, guide bushings and steady rests can optimize turning and milling processes while robots, gantry loaders and pallet changers can automated workpiece handling.

Narrow by Workholding & Handling Product Category

-

Workholding

- Actuators, Hydraulic & Pneumatic

- All Other Workpiece Handling, Loading & Feeding Equipment not specified

- Angle & Sub Plates

- Arbors, Expandable Workholding

- Centers, Live & Other

- Chuck Jaws & Collets

- Chucks, Collet Type (for Workholding)

- Chucks, Diaphragm

- Chucks, Gear

- Chucks, Index

- Chucks, Jaw Type

- Chucks, Magnetic

- Chucks, Power

- Chucks, Precision

- Chucks, Self-Contained

- Chucks, Special

- Chucks, Vacuum

- Clamps & Fixturing Devices

- Collets for Workholding

- Dividing & Indexing Heads

- Fixturing Systems

- Guide Bushings (for Swiss Lathes)

- Indexers & Rotary Tables

- Mandrels

- Pedestal Type Fixtures & Tombstone Blocks

- Steady Rests

- Vises & Vise Jaws

- Workholding, Custom

FAQ: Workholding & Handling

How hard is it to program a robot?

One trend in robotic automation technology is simplification in terms of programming, integration and setup. The LoadAssistant from Halter CNC Robotics is an example of a machine tool loading system that the company believes offers those benefits. Now available in North America, the LoadAssistant is said to easily connect to a shop’s existing CNC machine tool while providing the flexibility and reconfigurability to accommodate a range of jobs, as well as be easily moved from one machine to another. Plus, the company says it is well-suited for small batch sizes, and the average payback period for the system is six to 12 months.

Can a robot perform machining?

“Robot” is the first picture that comes to mind when people think about automation, but it means more than that. Automation could be machines that are able to do more in one setup, one handling. It also refers to other options like pallet systems for moving work around, in and out of machines. It refers to software that can automate certain operations. The applicability of automation is changing, and it's becoming more of an option for smaller facilities and smaller batches.

Automation is not a replacement or an alternative for people. The people in manufacturing who are apt to be most difficult to find are the high-skill, high-knowledge manufacturing employees, and really, automation can't take the place of what they do. There's no way to automate the kind of value they bring to the process. The case for automation really has more to do with augmenting, expanding and amplifying what those high-value people can do. So, find every repetitive task that people like that might do and find ways to automate them to set these people free for the higher-value work.

Machine shops can start small with automation, and one of the ways to do that is to, for example, start with quick-change workholding. And from there, maybe they bump into using a robotic loader and pallet pool and then they can do offline setup. From there they can jump into integrated robotic systems. The key is to start small and then set it up, step by step by step.

(Source: Practical Approaches to Automation)

How do I fixture 3D printed parts?

3D-printed fixtures can be custom designed for unique parts, and this process moves machining of metal fixturing components out of the toolroom while reducing production costs. The 3D-printed fixtures hold the piece while it is being nailed in the welder and ensure the precision and accuracy of the nail placement. This speeds the process because it eliminates the need for repeated manual adjustment of the fixtures. It also saves time from machine operators placing one nail at a time using traditional machining.

(Source: With 3D Printing, Fixture Making Goes from the Tool Room to the CAD Room)

Get Listed!

Thousands of people visit this Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.