Valves in Space

All of these valves need to be built to precise fits and finishes and to stringent performance requirements because “On a spacecraft, everything has got to work. If it breaks, you’re done.”

#materials #standards

3D Printing Materials

Q: 3D printing and additive manufacturing have become buzz words in various industries, but what do they mean in the context of valves, and what materials are involved?

#materials

Material Q&A: Elastomer and Plastic Materials

Question: What is the difference between plastic and elastomer?

#materials

Hardfacing for Valves: Materials and Processes

Valve internals, such as seats and closures, are often at risk of erosion, abrasion, corrosion, galling and damage from cavitation.

#materials

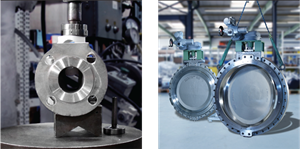

Conval: Camseal Metal-Seated Ball Valves Feature New Stem Position Indicator Disc

Conval recently announced that its popular Camseal© metal-seated, forged ball valves feature a new Stem Position Indicator Disc for easy, precise on-site identification and inspection of the open-close status of the valve.

#materials #ball-butterfly-plug

Creep Strength Enhanced Ferritic Materials in Thermal Power Applications

The designers of modern thermal power plants continue to work hard to improve plant efficiency by increasing the heat rate as a function of main-steam pressure and temperature.

#pressure-relief #materials

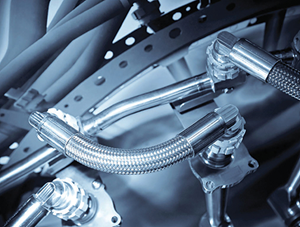

Understanding Surface Finish in Metal 3D Printing of Valves

While metal AM provides a host of positive advantages, it’s important to understand the realities of as-printed surface roughness.

#materials #basics

The Challenges of Chlor-Alkali

With the introduction of new materials and the evolution of valve design over the years, the days when fluid handling operators were limited by the number of valve types available to control the process are long gone.

#materials

The Magic Behind the Metal

Like the superhero that can leap tall buildings, the valve industry is made of steel.

#basics #materials

Gaskets Are Not Created Equal

Gaskets are near the bottom of the food chain of valve components; trim, body materials and packing seem to get a lot more press.

#materials #components #maintenance-repair

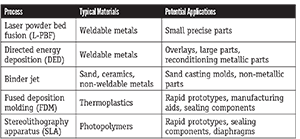

Metal Additive Manufacturing in the Valve Industry

Metal Additive Manufacturing (AM) is a fascinating technology that has gained acceptance over the past several years.

#materials #automation

Interior Coatings for Waterworks Valves

Since the 1990s, two types of epoxy coatings have been commonly specified and used for iron valves in the waterworks industry: fusion-bonded epoxy and liquid epoxy.

#materials

Passivation and Pickling

Q: I have customers that ask for their stainless-steel valves to be pickled and I have others who ask for them to be passivated.

#materials

Thermal Spray Coating

Q: What are the pros and cons of using a thermal spray coating like HVOF?

#materials

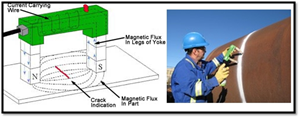

Magnetic Particle Examination: Not the Only Way to Test for Flaws

Magnetic Particle Examination (MT) is a popular, relatively low-cost method to perform nondestructive examination on ferromagnetic materials.

#materials

The New Version of NACE MR0103

Q: How do the requirements in this International Organization for Standards (ISO) document differ from those in the previous version?

#standards #materials

Portable Alloy Verification Devices

Q: What are the differences between the results you get from a portable alloy verification device and the results you see on a supplier’s certified materials test report (CMTR)?

#materials

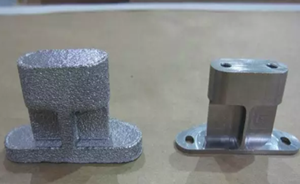

Cast vs. Forged: The Ongoing Debate Takes a New Direction

In the valve industry, the cast versus forged debate has been around for many years.

#materials #standards

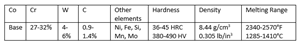

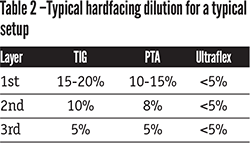

Hardfacing Alloys and Processes for Advanced Ultra-Supercritical

Cobalt-based Stellite 6 has been the workhorse for providing improved wear resistance and service life in valve components installed in power generating facilities for over 75 years.

#maintenance-repair #components #materials

The ASME Code Process for a Code Case: Non-Traditional Manufacturing Methods/Materials

What are ASME Code Cases and how do I get one?

#standards #materials