The VMA Welcomes its Newest Member, JACQUET Mid-Atlantic

JACQUET is an established market leader in the distribution of stainless steels and nickel alloys, specializing in the storage, processing and distribution of high-value metals in the form of plate and bar products.

#materials #VMAnews

U. S. Steel Announces Update on Metallics Strategy

U.S. Steel Corporation announced it would expand its low-cost iron ore competitive advantage and increase its self-sufficiency by supplying domestic feedstock to its growing fleet of electric arc furnaces (EAFs).

#materials

Free VMA Webinar: Valve Materials, Part 2

Tuesday, June 7, 2022 at 3 p.m. EDT.

#materials #VMAnews

Energy Startup SPARKZ to Build West Virginia Battery Factory

Edited by Margo Ellis, Former Editor, Valve Magazine

The company will partner with the United Mine Workers of America to recruit and train dislocated miners to be the factory's first production workers.

#materials

U.S. DOE Backs Lithium Battery Efforts

Edited by Margo Ellis, Former Editor, Valve Magazine

This workforce initiative is intended to boost the nation’s global competitiveness within battery manufacturing, while strengthening the domestic economy and clean energy supply chains.

#materials

CASE STUDY: Stainless-steel Piping Solutions for Remote Mine Sites

Edited by Margo Ellis, Former Editor, Valve Magazine

Stainless-steel piping has a long history on mine sites. The robust, corrosion-resistant material is ideal for mine process piping systems that are designed to provide a long service life.

#materials #VMAnews

Going the Distance: Mining’s Race to Meet Global Technology Thirst

When it comes to the world’s persistent and growing need for more raw materials, mining pushes forward to meet this moment while simultaneously striving toward decarbonization.

#automation #materials

PFAS Chemicals and PTFE: Should the Valve Industry Be Concerned?

By: Greg Johnson, VALVE Advisory Board Chair – CEO, United Valve

Legislation moving through Congress could affect the future use of thousands of PFAS chemicals (per- and polyfluoroalkyl). The house passed H.R. 2467 in July of 2021 and, though the bill is general in nature, it assigns the responsibility to the Environmental Protection Agency (EPA) for determining which PFAS chemicals will be controlled or banned altogether.

#materials

Dealing with Sand Erosion in Control and Choke Valves

Sand erosion in control and choke valves is a significant consideration offshore.

#materials

"Build America, Buy America" Signals Increased Commitment to U.S. Manufactured Goods

By: Margo Ellis, Former Editor, Valve Magazine

The Infrastructure Investment and Jobs Act includes major domestic procurement (“Buy America”) requirements for infrastructure materials.

#materials

Recycling Foreign Metals: Buyer Beware

The North American steel-making industry, with its historic record of quality control, is no longer the world’s top producer.

#materials #components

What’s Your Temperature?

For decades, valve manufacturers have provided the maximum recommended working pressures and temperatures for their products, based on the materials used in the pressure-containing parts.

#standards #pressure-relief #materials

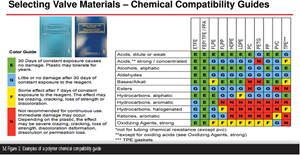

Selecting Non-metal Materials for Valve Components and Coatings

Non-metallic materials are commonly used for valve components, and the selection of non-metallic materials for valve design and for application-specific conditions is critical to ensuring product reliability.

#components #materials

The Materials That Make Up Valves

EDITOR’S NOTE: Materials used in the manufacture of valves and how they perform in different applications is a topic of huge interest to everyone who works with valves.

#materials

Valve Manufacturers Step Up During the Pandemic

Around the nation, companies and businesses have found ways to help with the challenges of the COVID-19 pandemic.

#VMAnews #materials

Welding Specifications Issues

Q: I need to qualify a welding procedure specification per the ASME Boiler and Pressure Vessel Code.

#standards #pressure-relief #materials

Valves Tough Enough to Handle Hydrofluoric Acid

Hydrofluoric acid: just the name itself strikes fear in some people, even among those who work around it every day.

#materials

Innovative Micro-porous Material Offers New Carbon Capture Options

A relatively new class of engineered materials known as metal-organic frameworks (MOFs) may provide an effective alternative for capturing carbon dioxide (CO2) from fossil fuel combustion emissions, which makes it a significant new option in emissions reductions.

#materials

The Valve Industry Finds Value in ESG Initiatives

The valve manufacturing industry in North America is one of the industries that have embraced this new way of thinking and is leading the way with the integration of environmental, social, and governance (ESG) initiatives. These initiatives range from valves designed to mitigate climate change to community involvement activities.

#materials #components

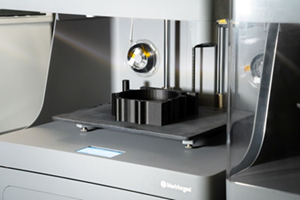

Accelerating Manufacturing Operations with High-Strength Plastic 3D Printing

3D printing in a factory 3D printing encompasses a family of processes that involve building up a plastic or metal part in an incremental layer-by-layer fashion.

#materials