Back to Basics: Pressure Relief Devices, Part 2

In Part 1 of Pressure Relief Devices, which appears in VALVE Magazine’s Winter 2016 issue, the author stresses the vital role pressure relief devices play in keeping end-user industries that deal with pressurized equipment safe.

#basics #pressure-relief #automation

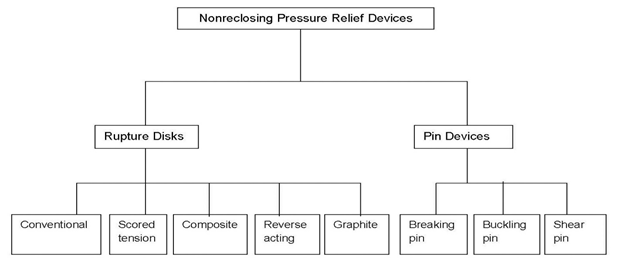

Nonreclosing–Type Pressure Relief Devices

A nonreclosing-type pressure relief device is designed to remain open after operation. Generally, a manual means of resetting is provided. If it’s not, the device is replaceable. Types of non-reclosing pressure relief devices are shown in Figure 1.

Rupture Disks

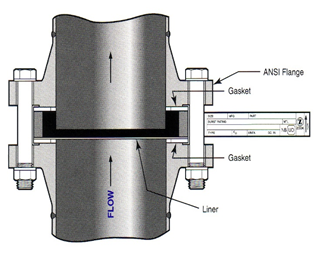

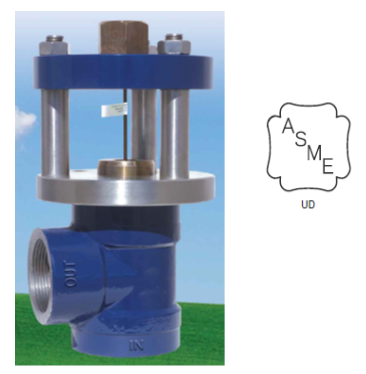

A rupture disk is designed to rupture at a predetermined pressure and temperature (Figure 2). If designed under ASME Boiler and Pressure Vessel Code, the rupture disks are stamped with the certification mark and one of the certification designators UD or TD.

Rupture disks are used where instantaneous and full opening of a pressure relief device is required. These devices protect vessels, piping and other pressurized systems from excessive pressure and/or vacuum.

The rupture disk is oriented with the process fluid against the concave side of the disk. As the pressure of process fluid increases beyond the allowable operating pressure, the rupture disk starts to grow. This growth continues as the pressure increases until the tensile strength of the material is reached and rupture occurs.

Before the 1930s, the use of rupture disks was limited. They consisted of flat metal membranes—a flat sheet of metals, generally copper, clamped between a pair of piping flanges. However, operating pressure caused bulging, and stretching the metal resulted in premature failure within 50% of disk rating.

In the 1950s, prebulged disks made of Monel, Inconel and stainless steels were developed that operated at 80% of their rated pressures. Scored rupture disks were introduced in the 1960s, and these designs were nonfragmenting, permitting operation up to 90% of rated pressure. In the 1970s, reverse-acting rupture disks were introduced.

Currently reverse-acting rupture disks with knife blade can be used up to 95% of operating pressure. Many varieties are available classified under the following categories:

- Conventional rupture disks

- Scored tension rupture disks

- Composite rupture disks

- Reverse acting rupture disks

- Graphite rupture disks

Conventional Rupture Disks

A conventional rupture disk is a prebulged solid metal disk designed to burst when overpressured on the concave side (Figure 3). After bursting, the domed rupture disk fragments.

This type of disk with a flat or an angular seat provides satisfactory service if operating pressure is 70% or less of the rated burst pressure and when limited pressure cycling and temperature changes are present. The main advantages of this type of rupture disks are:

- There are a broad range of applications for gas and liquids.

- They are available in various sizes, burst pressures, temperatures and materials.

The working principle behind the conventional rupture disk is that it has no moving parts, and it is a simple, reliable, full-opening and faster-acting device than other pressure relief devices. The rupture disk assembly is comprised of two parts:

- The disk, which is the thin, metal diaphragm bulged to a spherical shape to provide both a consistent burst pressure within a predictable tolerance and an extended service life, and

- A rupture disk holder, which is a flanged structure designed to hold the rupture disk in position.

The disk may have a flat seat or a 30o angle seat.

Scored Tension-loaded Rupture Disks

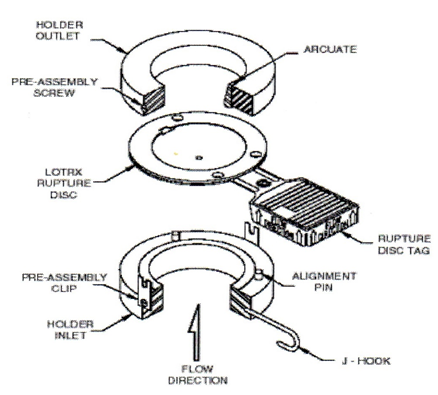

A scored tension-loaded rupture disk is designed to open along scored lines (Figure 4). Because the score lines control the opening pattern, this type of disk is generally nonfragmenting. It allows up to 85% operating pressure to disk burst pressure.

The main advantages of the scored tension loaded rupture disks are:

- They are nonfragmenting.

- Vacuum support is not required.

- There are a broad range of applications.

- They are available in various sizes, burst pressures and materials.

Composite Rupture Disks

A composite rupture disk is a flat or domed metallic or non-metallic multi-piece construction disk (Figure 5). The domed construction disk is designed to burst when overpressurized on the concave side. The flat composite disk is designed to burst when over pressurized on the side the manufacturer designs. The main advantage of composite rupture disks are:

- The disks allow use of corrosion-resistant materials in lower pressure service.

- They are smaller in size than solid metal disks.

- Generally, they have advantages similar to those of conventional rupture disks.

Reverse-Acting Rupture Disks

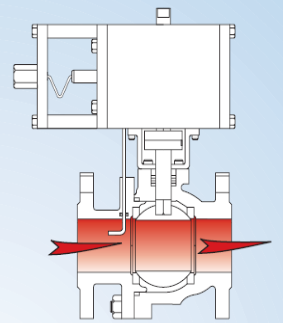

A reverse-acting rupture disk is a domed solid metal disk designed to burst when overpressurized on the convex side (Figure 6). As the burst pressure rating is reached, the compression loading on the rupture disk causes it to reverse, snapping through the neutral position and causing it to open by a predetermined scoring pattern or knife-blade penetration.

Reverse-acting rupture disks open by various methods, such as shears, knife blades, knife rings or scored lines. The main advantages of the reverse-acting rupture disks are:

- The disks can be operated to 95% of stamped burst pressure.

- They have longer service life under cyclic or pulsating conditions.

- They are constructed using thicker materials, providing greater resistance to corrosion.

- They are available in a wide ranges of sizes, materials, pressures and temperatures.

Graphite Rupture Disks

A graphite rupture disk is manufactured from graphite impregnated with binder material. It is designed to burst by bending or shearing (Figure 7). Graphite rupture disks are resistant to most acids, alkalis and organic solvents.

Graphite rupture disks are classified as mono-type, duplex-type, inverted-type and two-way type disks. The main advantages of graphite rupture disks are:

- They offer ultra-low rated pressure settings.

- They can be used for highly corrosive fluids.

- They eliminate back pressure effects on overpressure devices in common vent lines.

- They are easy to install and maintain.

Rupture Disk Accessories

Though rupture disks are simple pressure relief devices, some accessories make them more useful such as:

- When connected to an electric alarm, a burst sensor is used to alert an operator when a rupture disk bursts. Once bursting of the disk is known, the operator can take immediate action to protect the pressure relief valve from further damage.

- An alarm system with an alarm monitor uses a normally closed electrical circuit. When the disk ruptures, it breaks the circuit triggering the alarm. If used in conjunction with a burst sensor, it immediately alerts an operator of a ruptured disk.

- Heat shields are installed upstream of the rupture disk in high-process-temperature applications to reduce the temperature at the rupture disk.

- Baffle plates are used to deflect process discharge away from personnel and equipment. These are effective when rupture disks are venting to atmosphere.

Pin Devices

A second type of non-reclosing pressure relief device is a pin device, which functions similar to rupture disks. A pin device is actuated by static differential pressure or static inlet pressure. They are designed to function by the activation of a load bearing section of a pin that supports a pressure containing member (Figure 8). If designed under ASME Boiler and Pressure Vessel Code, the pin devices are stamped with the certification mark, and one of the certification designators UD or TD.

A pin is the load-bearing element of the device. Pin device housing encloses the pressure-containing members.

Pin devices are often used in applications where rupture disks must be replaced because of frequent failures. Replacing rupture disks with pin devices allows pressure running slightly closer to design pressure which can mean a capacity increase.

Rupture pin technology was developed in 1986 to solve valve failure problems for Exxon and Shell in Holland. In the United States, rupture pin technology was introduced in 1990. ASME approved the use of the buckling pin under ASME Code Case #2091 in May 1990. Since then, ASME has permitted the use of pin devices designed under the ASME Boiler and Pressure Vessel Code. Currently many types of pin devices are available classified under the following categories:

- Breaking pin device

- Buckling pin device

- Shear pin device

Breaking Pin Devices

A breaking pin (also called rupture pin) device is actuated by inlet static pressure (Figure 9). The device is designed to function by breaking a load-carrying section of a pin that supports a pressure-containing member. An O-ring on the piston is used to make a bubble-tight seal.

The main advantages of breaking pin devices are:

- They are not subjected to premature failure from fatigue.

- They are suitable for operating closer to set point.

- They are suitable for operating as low as 0.1 psi.

- When installed under a pressure relief valve, a breaking pin device can be reset without removing the pressure relief valve.

The working principle is that a breaking pin device usually consists of a piston on a seat, retrained from movement to the open position by a slender round pin. The pin buckles at set point from an axial force caused by the system pressure acting on the piston area. The buckling point of the pin is determined by the unrestrained pin length, the pin diameter and the modulus of elasticity of the pin material.

The breaking pin device can be designed to sense system pressure only, or differential pressure only. The device can have a set pressure from 0.1 to 35,000 psi.

Buckling Pin Devices

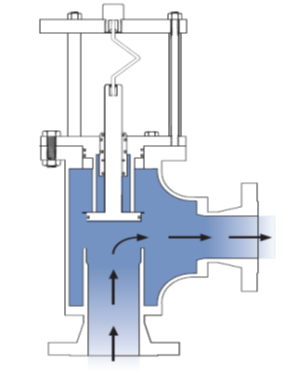

A buckling pin device provides quick and simple rest without removing the device from the pressurized system (Figure 10). The device is designed to function by the buckling of an axially loaded compressive pin that supports a pressure-containing member.

The buckling pin device has three primary components: a rotating disk, a flanged body and an external enclosure and mechanism. When an external load is applied to a straight cylindrical pin, it buckles at a specific load. The main advantages of the buckling pin devices are:

- The set pressure remains unaffected by the cycling/pulsating pressure.

- They have easy external settings.

- The buckling pin is totally protected with a rugged enclosure.

- They can be used up to 95% of the set pressure.

Shear Pin Devices

A shear pin device is actuated by inlet static pressure. The device is designed to function by the shearing of a load-carrying pin that supports a pressure-containing member.

The force of overpressure forces the pin to buckle and the device to open. The device can be reseated after the pressure is removed and a new pin can be installed.

Pin Device Accessories

Pin device accessories include:

- The proximity device senses piston opening and gives a remote warning of opening.

- The remote operation mechanism allows a pin device under pressure to open or close by the force from an energized solenoid coil. A remote signal can energize the solenoid.

- A pressure balancing piston is used so that containment pressure does not affect set point. As a result exact set point is maintained.

Mohammad A. Malek, PhD, PE is pressure systems manager with Stanford University – SLAC. He is also an instructor with ASME and teaches ASME Course PD583 - Pressure Relief Devices at home and abroad. Dr. Malek is the author of the book Pressure Relief Devices published by McGraw-Hill. Reach him at malekm@asme.org.

RELATED CONTENT

-

A Primer on Pressure Seal Valves

High pressure, high-temperature applications require a safe, leak-free pressure-containing boundary.

-

The Rationale Behind Valve Characteristics

Back in the “early days,” we were taught that, to properly control flow, we should select a linear valve characteristic when the valve controls more than 25% of the piping system pressure drop at full flow.

-

Direct-Sealing Diaphragm Valves Offer Novel Approach

As modern industries such as hydrogen electrolysis and biotech make dramatic technical advances, engineers and researchers must sometimes turn to nontraditional process control systems.

Unloading large gate valve.jpg;maxWidth=214)