Best Practices in Pressure-Relief Valve Maintenance and Repair

In their presentation at the Valve Repair Council Repair Meeting & Exhibition, Nov. 1 and 2, 2012, in Houston, Bob Donalson and Kevin Simmons of Pentair Valves & Controls shared valuable information about maintenance and repair programs for pressure-relief valves.

#pressure-relief #maintenance-repair #controls

ASME covers the type of device allowed, the type of PRV allowed (pilot-operated and direct spring only), the minimum maximum allowable working pressure (MAWP) of vessel to be protected (15 psig), the required opening pressure with respect to MAWP and allowed accumulation with respect to MAWP. Also included in the standard: capacity certification, installation, mechanical requirements, materials, quality assurance of manufacturing, production testing, welding and non-destructive evaluation (NDE), and the size and quantity of PRV/PRD required for each vessel. All of these requirements are shared responsibilities of the manufacturer, user and OEM.

Experience is Essential

The worst case scenario should also be considered whenever sizing PRVs. Taking into account the possibility of blocked discharge, external fire, a tube rupture in the heat exchanger, thermal expansion, a runaway reaction, power failure, or over filled storage vessels will insure the best possible choice.

Sizing Pressure-Relief Valves

The primary factors required when sizing pressure-relief valves are:

- Set point: The point at which the valve needs to open, which is normally the MAWP of the vessel; often expressed in PSIG or BARG.

- Flowing capacity: The amount of process fluid the valve must flow to protect the system when the valve is open, which is often expressed in GPM, SCFM or Lbs./hr

Capacity and set point are interrelated. As pressure (set) increases, flow also increases. No one PRV is best for all applications and additional factors to consider when sizing and selecting PRVs include temperature, composition of process fluid or gas, piping arrangements including existing flange size, dimensional restrictions (height), the type and degree of back pressure, operating ratios, preferred or required materials of construction, preferred operating style of the valve, single vs. multiple PRV installation and the weight of the device.

After noting that improper installation is one of the common causes of ongoing problems with pressure relief valves, Donalson and Simmons outlined best practices for repair of PRVs. They included:

- Verify and record nameplate information and be sure to protect the nameplate while servicing the valve. This will prevent loss of important information.

- Check the condition of seal wires. Seals will indicate who assembled/manufactured the PRV or the last repair organization to service the PRV.

- Visually inspect the PRV during disassembly. This is critical, and parts should be inspected per manufacturer instructions.

- Proper cleaning of parts is also vital, but overly aggressive cleaning methods may damage delicate or highly machined surfaces.

- It is also essential to follow the manufacturer’s work instructions for assembly.

Testing Guidelines

Once the repair is completed, the testing should also follow strict guidelines: test media selection, test stand volume/design, gage calibration and selection, set point definition, temperature/back pressure corrections, accepted alternate test methods, set point tolerance, seat tightness standards, and field vs. shop testing.

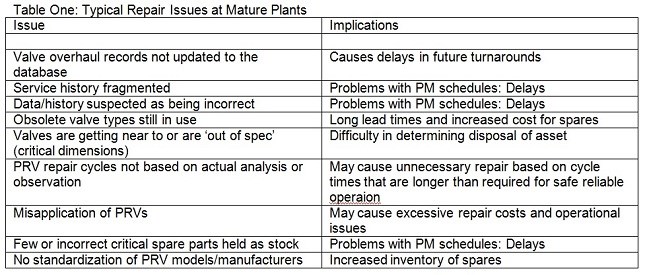

Understanding repair parts, managing them and having spare valve inventory is key to controlling costs. By understanding the typical repair issues and having an established asset management protocol, facilities can avoid repeat issues, reduce costs and improve safety.

A good summary to take from this presentation: Take no shortcuts and follow manufacturers’ recommendations when repairing valves. Experience is critical.

Kate Kunkel is senior editor of VALVE Magazine. You may contact her at kkunkel@vma.org

RELATED CONTENT

-

Operational Basics of Safety Valves

These spring-loaded valves provide overpressure protection for downstream equipment.

-

Welding Specifications Issues

Q: I need to qualify a welding procedure specification per the ASME Boiler and Pressure Vessel Code.

-

Pressure Relief Valve Basics – Spring-Loaded Safety Relief Valves

Learn for the first time or brush up on this common valve product.

Unloading large gate valve.jpg;maxWidth=214)