Solenoid Valves: Direct Acting vs. Pilot-Operated

While presenting in a recent VMA Valve Basics 101 Course in Houston, I found myself in a familiar role: explaining solenoid valves (SOVs) to attendees. (I work with solenoids so much that one VMA member at that conference joked that I needed to be wearing an I Heart Solenoids t-shirt). During the hands-on “petting zoo” portion of the program, which involves smaller groups of attendees, one of the most frequently asked questions I get from people came up: What’s the difference between direct-acting and pilot-operated SOVs, and how do we make a choice?

#basics #solenoids #automation

While presenting at a recent VMA Valve Basics 101 Course in Houston, I found myself in a familiar role: explaining solenoid valves (SOVs) to attendees. (I work with solenoids so much that one VMA member at that conference joked that I needed to be wearing an I Heart Solenoids t-shirt). During the hands-on “petting zoo” portion of the program, which involves smaller groups of attendees, one of the most frequently asked questions I get from people came up: What’s the difference between direct-acting and pilot-operated SOVs, and how do we make a choice?

First, let’s remember when discussing SOVs, the solenoid coil is the electrical apparatus of the valve. Think of it as the actuator with the balance of the valve being mechanical. With that in mind, a prescribed voltage would be required to energize the SOV to make it fully functional.

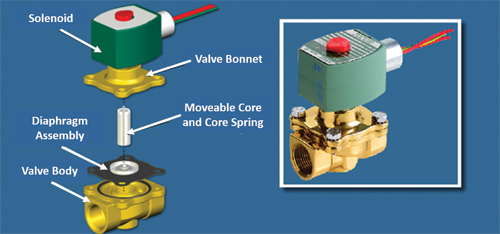

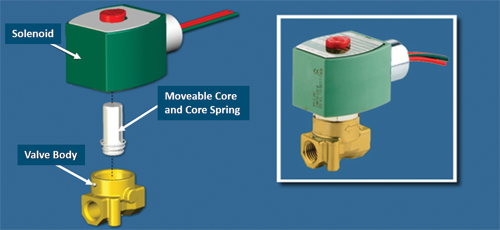

Direct acting is the type of SOV with the least amount of moving mechanical parts. Typically, a movable core (or plunger), spring and/or fulcrum lever are found inside the valve body. Once the SOV is energized, the magnetic field created in the solenoid coil attracts the movable core towards the coil’s center.

The movable core, which was sealing an orifice, now allows for media (air/inert-gas, water or oil) to flow through the SOV from inlet to outlet (downstream). Note that all this “work” is a result of the fact the mechanical parts responding to the flux of the magnetic force are on or off.

A pilot-operated SOV also uses its coil to lift a movable core, but these valves have a pilot and bleed orifice that enables them to use a fraction of the line pressure from the media source to assist in the lift of either a diaphragm or piston. (Features that are not included in a direct-acting SOV).

But why are there differences? Direct-acting SOVs, by design, are a zero minimum pounds per square inch gauge (psig); in fact, most can handle a vacuum pressure of -14.7 psig and also much higher pressure ranges. There are several tradeoffs associated with this. The main orifice size must remain smaller because if a larger pipe size is allowed, the coil would need to be larger to create more power to pull the moving plunger through the greater volume of media.

Conversely (internal) pilot-operated SOV, which is ‘borrowing’ from the media at the inlet, will also lift a diaphragm or move the piston enough to allow media to flow through a larger orifice, thus allowing pipe sizes to be greater than the direct acting. Additionally, the coil is doing less work, using less power draw or wattage (in most cases). This SOV with larger pipe sizes will be able to achieve higher Cv (Kv), therefore, greater standard cubic feet per minute or gallons per minute—generally more flow where necessary.

So again, what are the tradeoffs here? Pilot operated can also be zero minimum pilot pressure while maintaining the larger Cv. Flow ratings, added springs, and other mechanical attributes of the diaphragms or pistons will mean more movable parts, reducing maximum pressure rating, greater wattage usage from the coil and usually more cost per unit.

There are circumstances where the choice between a direct acting or pilot operated will overlap on pipe sizes. Using most of the information above, the end user must decide the best flow factor Cv (Kv), minimum pressure in the line, maximum pressure in the line, wattage consumption and cost of ownership (preventive maintenance, repair or replacement).

The topic of direct acting vs. pilot operated will be suitable across nearly all SOV types and configurations. For users, this may require 2-way, 3-way, or 4 way, direct-acting or pilot-operated SOVs; as with most equipment, the application will work best with the right educated choice.

JOHN MOLLOY is ASCO Training Manager for Emerson. Look for him at the next Valve Basics event, where he’ll probably be wearing an I K Solenoids t-shirt. Reach him at John.Molloy@emerson.com.

RELATED CONTENT

-

When Accessories Become Necessities

Specification sheets for selecting automated valves list requirements for the valve and actuator but often lump all other devices together as related instrumentation or accessories.

-

High-precision positioner for industrial valves

ifm’s MVQ positioner is used to move valves to the required position, based on a signal from the control level indicating the degree to which the valve is open in percentages.

-

The Different Types of Solenoid Valves and How They Work

Solenoid valves are automatic flow control devices popular across different industrial applications.

Unloading large gate valve.jpg;maxWidth=214)