Editor's Product Picks

Editor’s Product Picks

#iiot #controls #ball-butterfly-plug

Bray Launches New Cx Line Products

The new Bray Cx line is comprised of valves designed with a unique application in mind. The 2-Cx provides a lined valve for superior chemical resistance. It features a live-loaded, self-adjusting sealing system with certified packing and its seat energizer extends completely around the seat for zero leakage.

The 3-Cx resilient seated butterfly valve features a molded-in seat design for durability and reliability. The precision profiled disc sealing edge extends the valve life by reducing seat wear.

The 4-Cx double offset valve is designed for the most demanding applications and features an adjustable, live-loaded stem sealing system with certified packing.

The Tri Lok-Cx triple offset valve has field replaceable sealing components and the splined stem connection offers maximum strength and minimizes hysteresis.

The new products will all have Bray DIGI-ID digital asset tags providing digital access to standardized product data via a QR Code in accordance with IEC 61406 (DIN 91406). bray.com

Flowserve Valtek TX3 Molten Salt Triple-offset Butterfly Valve

The Flowserve Valtek TX3 Molten Salt triple-offset butterfly valve provide concentrated solar power (CSP) plant operators with reliable performance, tight shut-off and minimized maintenance in molten salt applications.

It can withstand temperatures ranging from 260ºC to 600ºC (500 ºF to 1,112 ºF) with standard live-loaded hybrid or Thermiculite® packing. It maintains the packing load for constant external sealing during thermal cycling. flowserve.com

New Valve-Based Leak Monitoring Sensor for Water Distribution

Echologics, LLC, a subsidiary of Mueller Water Products Inc., launched its EchoShore-DXe acoustic leak monitoring sensor, a valve-based sensor that extends the leak monitoring capabilities of the Echologics EchoShore-DX system. The sensor can attach to virtually any access point in a water distribution network — and works in tandem with the EchoShore-DX hydrant-based sensors — so utilities can get coverage where needed.

Like the hydrant-based EchoShore-DX sensors, the valve-based EchoShore-DXe sensors have a battery life of up to 10 years and support communications via LTE Cat-M1 and Narrowband Internet of things (NB-IoT) networks. echologics.com

New Valves Reduce Costly Product Evaporation Losses

Groth Corporation announces two new products: the Model 12E and Model 12F weight-loaded, pressure/vacuum relief valves (PVRV). The PVRVs achieve both superior sealing performance and industry-leading flow rates while allowing customers to reach the required flow with a potentially smaller-sized valve, lowering the cost to protect tank equipment and onsite personnel.

The Model 12E and 12F feature 10% overpressure technology, allowing customers to set their valves closer to flowing pressures, minimizing product losses and maximizing profit. grothcorp.com

Two New PRVs from Emerson

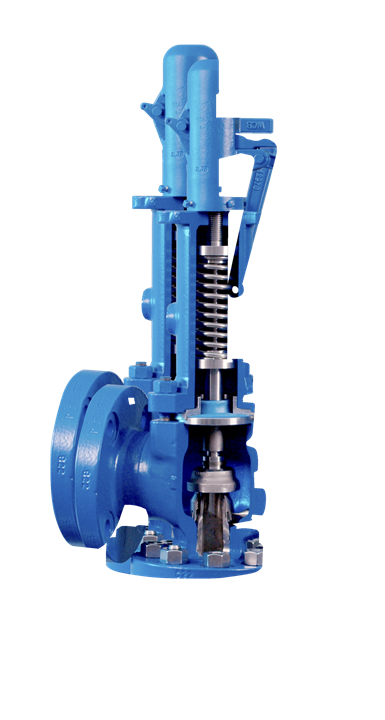

Crosby J-Series PRV with balanced diaphragm.

Photo Credit: Emerson

Emerson has announced the release of two new-to-the-world technologies for the Crosby J-Series pressure relief valve (PRV) product line. The first is a balanced diaphragm, which eliminates the need for bellows in PRVs, while providing balanced operation against backpressure to lower the cost of ownership and enhance performance. The second technology is bellows leak detection, enabling remote detection of bellows ruptures in PRVs, with the capability to reduce and accurately calculate volumetric emissions in real-time. emerson.com

Spirax Sarco Introduces Two Smart Positioners

Spirax Sarco, aglobal leader in steam system engineering and management, has expanded its product line to include the new SP7 and SP8 Smart Positioners. These new positioners are mounted onto a control valve to allow a central control system to remotely control the valve with an analog input signal.

SP7 and SP8 positioners have a die cast aluminum case and cover, and are designed to work in the harshest conditions, especially applications with high levels of vibration without failure, up to 10g/80 Hz. spiraxsarco.com

Second-Gen Top-Entry Valve from Cornerstone

The TE-4 ball valve from Cornerstone Valve is available up to 4-inc, with custom sizes available. The in-line repairable valve can be used in applications from -20° F to 1200° F, with higher temperatures available. The ball’s entire surface is lapped, eliminating coating transition peaks that can create friction and higher torque during cycling. And downstream seats are locked to prevent blowout in back pressure conditions. The top-entry valve allows for easier maintenance and service, and the challenges of realignment that can occur with 3-piece designs. The valves meet a range of ANSI/ASME 150-4500 pressure class, and ASME B16.34 standards. cornerstonevalve.com

Dan-Ex DBB Valve from Western Valve

Designed as an improved version of its General Twin Seal Valve, the Dan-Ex was created to improve the integrity for DBB applications. The Western Valve DAN-EX is an accepted block and bleed valve as it has two independent seating slips that are mechanically expanded against the body seat by the downward movement of the tapered plug. The seating slips will seal with both high and low pressure imposed on both upstream and downstream sides of the valve. This contains the product in the center cavity between the two independent slips, and the body bleed valve can be opened to verify 100% positive shutoff at high or low pressure.

In the fully open position. The tapered plug of the vale is lifted fully. Slips are held to the plug via dovetails, and retracted away from the valve body, protected from the flow. During rotation of the handwheel, slips maintain clearance from the body, eliminating scoring and rubbing. When the valve is fully closed and slips are fully seated, the valve provides full DBB shutoff as well as a secondary metal-to-metal firesafe seal for both upstream and downstream closure. The bidirectional valve doesn’t rely on springs for flow or shutoff. An option is available for a top-mounted actuator in sizes from 2- to 12-inches. westernvalve.com (Editor’s note: The website was printed incorrectly in the print issue. This is the correct site.)

Koso Series G120 Globe and Angle Valves

The thread retained seat ring of the G120 eliminates concern over thermal expansion issues and the need for elastomeric gaskets. This design utilizes a single metallic gasket at the body to bonnet interface. This all-metal construction makes this design ideal for many difficult and hazardous chemical applications. The geometry of the trim components simplifies manufacturing when high alloy materials are required.

The contoured plug of the G120 is available with 3 standard trim sizes (full, 60% and 40%) and up to 7 reductions in some sizes. The 1/2" - 1" valves are also available with spline trims for precise control of extreme low flow applications. A variety of extension and bellows seal bonnet options further enhance this product’s capability in chemical applications.

Available from ½- to 6-inch bodies in globe and ½- through 2-inch in angle valves, the valves are rated to ANSI Class 150, 300 or 600. Ultra-low temperature extension bonnets are available for services down to -320°F (-196° C). kosohd.com

New Gilmore Check Valve Designed for Well Stimulation Pressure Control

The new Gilmore Agiliti™ Check Valve was designed from the ground up as a flow control solution for well stimulation pressure control systems. The valve minimizes the maintenance burden on Gilmore’s pressure pumping customers with a service life of more than 400hrs. Customers will not need to perform any maintenance on the check valve for the duration of a typical four (4) well pad. It is a drop-in replacement to existing check valves to prevent backflow to upstream assets, and was designed to keep operations flowing for longer intervals between maintenance cycles, reducing downtime, labor and costs.

The valve was designed to API 6A requirements, and qualified to 1000 cycles at a maximum flow rate of 16 BPM. Weighing 212 lbs, and with a working pressure of 15,000 psi, the valve has 3-in. 1502 hammer union connections. For more information on the Gilmore Agiliti™ Check Valve download the product sheet here https://bit.ly/3V0YWfY

RELATED CONTENT

-

Back to Basics: The Nuts and Bolts of Torque and Tension

Torque is a force that causes an object to rotate, while tension is a force that causes an object to stretch or elongate.

-

Valve Selection for Bypass of Control Valves: A Case Study

A bypass line including a bypass valve is typically installed to provide continuous operation in case of regular maintenance of a control valve.

-

Valve Basics: Electric Actuator Controls

Electric valve actuators control the opening and closing of valves. With a motor drive that provides torque to operate the valve, these actuators are frequently used on multi-turn valves such as gate or globe and also on ball, plug and other quarter-turn valves.

Unloading large gate valve.jpg;maxWidth=214)