Enhanced Software Helps Unlock the Benefits of Control System Virtualization

Control personnel can quickly deploy a virtualized infrastructure that improves performance while also future-proofing their operations.

#VMAnews #controls

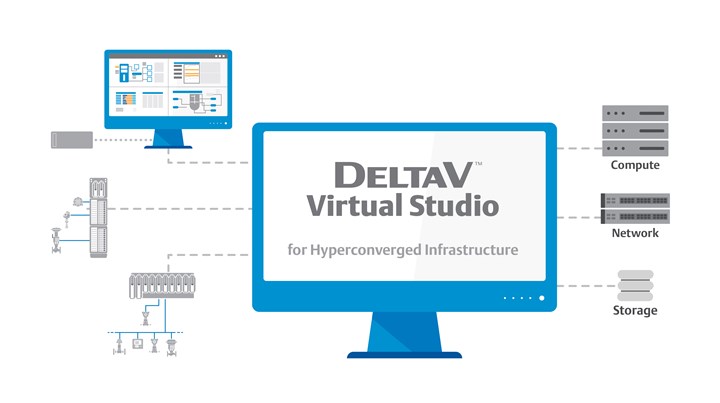

With the latest release of Emerson’s DeltaV Virtual Studio, control personnel can quickly deploy a virtualized infrastructure that improves performance while also future-proofing their operations. That’s because this software now incorporates support for hyperconverged infrastructure (HCI), helping overcome the traditional hurdles associated with the virtualization process.

Manufacturers have long understood the value of virtualization, but when it comes to virtualizing control systems, the process has typically been costly and complex, requiring a high degree of IT expertise. Recognizing these challenges, Emerson designed the latest version of its Virtual Studio software with enhanced automation for easy setup and maintenance of virtual DeltaV systems. Virtual operator workstations and application servers can be created using templates without software installation and added to the control network without complicated virtual network mapping.

Leveraging the software, manufacturers can:

- drive performance with a unified virtualized system incorporating compute power, network configuration and storage into a single tightly integrated platform that enables more efficient system deployments in production, development, testing and training environments.

- reduce energy usage with a smaller hardware footprint resulting from the consolidation of workstations on host servers to reduce computer hardware.

- achieve higher availability by reducing recovery times for workstations with automatic failover.

- dynamically grow their environments with a scalable infrastructure that offers configuration flexibility and doesn’t disrupt operations.

Learn more about Emerson’s DeltaV Virtual Studio for Hyperconverged Infrastructure by clicking here.

RELATED CONTENT

-

Editor's Product Picks

Neles introduces valve-sizing and selection software for all intelligent automated process valves.

-

Valves in Oxygen Service

In his presentation at VMA’s 2017 Technical Seminar, Kurt Larson, a process control engineer for Air Products, spoke about the inherent danger of the oxygen production business and how it is particularly important for end users and valve manufacturers to work closely together.

-

CASE STUDY: Stainless-steel Piping Solutions for Remote Mine Sites

Stainless-steel piping has a long history on mine sites. The robust, corrosion-resistant material is ideal for mine process piping systems that are designed to provide a long service life.

Unloading large gate valve.jpg;maxWidth=214)