Process Instrumentation in Oil and Gas

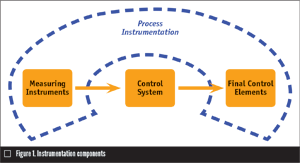

Process instrumentation is an integral part of any process industry because it allows real time measurement and control of process variables such as levels, flow, pressure, temperature, pH and humidity.

#pressure-relief

Mohamed Salaheldin, currently quality and energy efficiency improvement manager, Sidi Kerir Petrochemicals Company (Sidpec) in Egypt, is a good source for gaining an understanding of best practices, maintenance and future prospects of process instrumentation from an industrial standpoint. The answers here are his. Salaheldin has more than 18 years of experience in instrumentation and control, engineering management, quality engineering and energy efficiency. His current responsibilities include implementation of corrective and preventive actions for critical problems and energy management system implementation according to the requirements of ISO 50001.

Q: What is process instrumentation, and why is it necessary?

The input devices (instrumentation) measure four important operating parameters: pressure, temperature, flow and level. Advanced, online analyzers that measure process composition are also considered an element of process instrumentation.

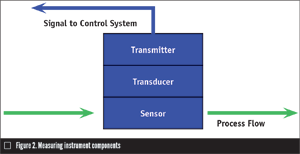

The instrumentation consists of three main components:

- A sensor, which is sometimes called a primary measuring element, to measure required physical properties

- A transducer, which converts the sensor signal into a standard signal form that suits the control system such as a pneumatic signal (3-15 psi), an electric signal (4-20 mA), a digital signal of Foundation Fieldbus, etc.

- A transmitter, which prepares the transducer signal for transmission without loss and then transmits it. Smart transmitters also send meaningful data about the status of the measuring instrument as a whole.

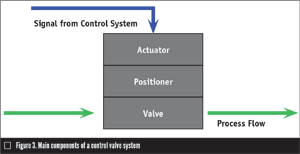

Process instrumentation includes the most common control element, the control valve, which consists of an actuator that converts the output signal from the control system into a signal that can allow the valve to respond, the positioner for adapting the response and the valve. Smart positioners can currently send and receive useful data to and from the control system for predictive maintenance purposes.

Q: What are key considerations an end user should make to ensure success when dealing with existing instruments and selecting process instrumentation technology?

Selection criteria should be set according to the needs of the end user and must include at least the following parameters:

- Performance characteristics: This includes all the specifications regarding the required performance of instrumentation in a certain process such as accuracy, resolution, rangeability, sensitivity, repeatability, dynamic performance, etc.

- Environmental conditions: This is essential for specifying the necessary protection to ensure that instrumentation is working properly with regard to safety requirements and operational conditions.

- Influences on processes: The extent to which the processes will be disturbed during the measuring process should be included. For example, significant pressure loss can be caused by some flow measurement techniques.

- Durability: Durability and ruggedness of process instrumentation should be considered according to application requirements.

- Maintainability and operability: Maintenance requirements and ease of use, as well as operation and effect on the running costs of instrumentation need to be weighed.

- Purchase cost: Initial cost should be considered according to the needs and situation of end-user requirements.

Q: What high-level best practices do you typically recommend for an end user to approach the process instrumentation design process?

Q: What are some common pitfalls you see end users encounter in the specification, design and/or application of process instrumentation and what can they do to avoid them?

A: Issues arise when engineers who may not have adequate training and background in a process write the specifications or follow the recommendations of sales representatives without the qualification to review the details. Another issue is equipment purchased strictly on lowest-priced bids.

To avoid such pitfalls, an end user should weigh price against application requirements so that reputable vendors, usually with the higher-priced products, are not excluded. Instrumentation engineers need to be recruited properly and trained continually to follow the highest standards to keep them familiar with state-of-the-art technologies. Engineers also should not hesitate to ask for help from other departments within the facility. For example, when specifying a new control valve, instrumentation engineers commonly do not have the essential experience in material selection so they should ask for guidance from mechanical engineers.

Q: What are recent technology developments in process instrumentation?

For example, due to the criticality of flow measurements, manufacturers continually develop new features for hard and severe applications. One type of flowmeter used in a wide range of industry sectors is the Coriolis mass-flowmeter. Multiple process variables such as mass flow, density and temperature are simultaneously measured, leading to accurate information about other process parameters such as volume flow, concentration, etc. Coriolis flowmeters can be as large as 12 inches.

Clamp-on ultrasonic flowmeters with transducers attached to the outside of a pipe are considered effective as portable flowmeters. Although this type was found many years ago, recent technology improvements make them more accurate and reliable.

New technologies in control valves for severe applications result in greater reliability and operability. However, the most effective new technology is smart positioners, which supply new features about self-diagnostic and analysis capability.

The challenge is to get the most benefits from data by applying analysis techniques using special software tools to support decision-making regarding optimized cost, waste reduction and enhanced productivity.

Q: How does industry intend to expose applications that don’t meet expectations?

A: In process instrumentation, like other fields of industry, there are both products that don’t meet expectations and those that do. Generally speaking, though, having the wrong application is not due to the wrong product; it is more often a mismatch between the actual needs and the process system ultimately ordered and installed.

An example might be a new -control-valve technology for severe applications where there is high probability of flashing and/or cavitation. The end user may decide to use this new technology to deal with a certain application in the facility. However, misunderstanding the actual application itself could result in poorer performance because the new technology might reduce flashing but create another problem within the system.

Another example is when an end user installs new process instrumentation compatible with a new control system and buys all the required software to get the best benefits of the new features. However, after the initial start-up, nobody in the plant can use the overwhelming data to work towards quality and productivity improvements.

Q: What are your thoughts on the future of process instrumentation?

A: End users should pay attention to the integration between the business layer and the operational layer of their process plants. Process instrumentation is the backbone of these systems and should be properly selected, especially with regards to reliability. The data supplied by new digital process instrumentation should be treated as valued information to be used in quality and productivity improvement within a facility. I believe wireless instrumentation will have an unbelievable role in the market in the next few years.

CHIKEZIE NWAOHA is a researcher at the Clean Energy Technologies Research Institute (CETRI), University of Regina in Regina, Saskatchewan. Reach him at chikezienwaoha@LIVE.CO.UK.

RELATED CONTENT

-

The Dos and Don’ts of Isolating Pressure Relief Valves

Typically, isolation valves are used to block off a pressure safety valve (PSV) from system pressure, so that maintenance on the valve or related equipment can be conducted without a shut down.

-

Back to Basics: Pressure Relief Devices, Part 2

In Part 1 of Pressure Relief Devices, which appears in VALVE Magazine’s Winter 2016 issue, the author stresses the vital role pressure relief devices play in keeping end-user industries that deal with pressurized equipment safe.

-

The Mighty Steam Trap

The steam trap is the device primarily responsible for automatic discharge of condensate from steam systems. It’s the same today as it was in the early days.

Unloading large gate valve.jpg;maxWidth=214)