Sustainable Protein Products: What's Ahead for Manufacturers?

As alternatives to conventional meat products are being introduced to relieve environmental and ethical implications of farming, process engineers are presented with both challenges and opportunities.

In recent years, people across the world have grown increasingly concerned about the environmental and ethical implications of raising livestock on a densely populated planet. As a result, alternatives to conventional meat products are being introduced and adopted rapidly, presenting both challenges and opportunities for process engineers as they work to design manufacturing practices to deliver these foods at reasonable cost and with the most efficient use of resources.

Biomass Fermentation and Mycelium Plant Meat

A family of products called fermented proteins are one field that is growing in popularity. While fermentation has been used in food preparation for years, recent technology is using fermentation for alternative protein production. The Good Foods Institute (GFI) defines “biomass fermentation” as “using high-protein content and rapid growth of microorganisms to efficiently make large amounts of protein-rich food.”

Also called fungi-based food, mycelium forms a filamentous, dense structure that mimics meat with excellent protein content and digestibility.

Biomass fermentation takes place in a bioreactor where environmental conditions key to the growth of the mycelium are closely monitored and controlled. Engineers are optimizing bioreactor design, but the process is already considered to be an efficient method of food preparation. Products made with this technique, such as Quorn, are widely available today in supermarkets.

Cultivated Meat

Also referred to as cell-based meat, cultivated meat is a new, innovative cellular agriculture process with the potential to feed more people using fewer resources than conventionally raised livestock. Unlike plant-based meat alternatives that only mimic the taste and texture of meat, cultivated meat is a real meat protein grown from animal cells in a bioreactor.

By leveraging the biotechnology that is already being used to produce medicines, cellular-based food technology can be utilized to produce beef, chicken or fish while improving food safety and security — all without harming any animals.

The cultivation process begins by harmlessly harvesting cells from an animal. The cells are grown in a stainless-steel bioreactor, similar to a brewery fermenter, where the biological process that happens inside an animal takes place in the bioreactor. The bioreactor, sometimes called “cultivator” in this process, is supplied with the necessary elements for building muscle, such as water, glucose, amino acids, vitamins, minerals, and growth factors. During the process, parameters such as pH, temperature, oxygen, and pressure are tightly controlled. Further refinement of the meat structure takes place after harvesting the cells, often using plant-based scaffolding to encourage the meat to grow in a certain form.

Cultivated meat is in its infant stages and the process has some significant design hurdles to overcome before it can be price competitive with conventional farmed meat. To produce cost-effective products that meet the market demand, cultivating meat requires high throughput, affordable input ingredients and minimized process costs.

Challenges & Opportunities

To be competitive with the cost of conventional farmed meat, the process of cultivating meat will have to be done on a very large scale. Industry leaders are using bioreactor technology know-how from the life sciences companies, but the scale required for producing medicine is much smaller than that needed for meat. Ideal parameters for best quality final product are also being studied. Process conditions such as pH, dissolved oxygen and glucose must be optimized for healthy and efficient cell growth. Automation around those parameters will also be a challenge as scientists learn how to best measure and control them.

To produce cost-effective products and meet market demand, cultivating meat requires high throughput and minimized process costs. Processes where valves are used create opportunities for the valve industry to contribute to cultured meat optimization.

Perfusion reactor for cultured meat

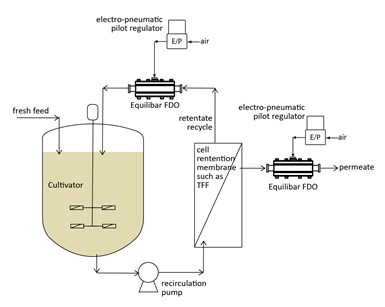

Schematic of general perfusion process with direct-sealing diaphragm back pressure regulators maintaining transmembrane pressure.

Photo Credit: Equilibar.

Cultivated meat manufacturers are developing best practices for scaled up bioreactor design including batch, continuous and perfusion used in bioprocessing. Perfusion reactors offer key benefits over standard batch-style processes for the cultivated meat cell growth process due to the lengthy time it will take for the cells to grow, and the volume of meat required to maintain reasonable cost. The long processing time requires filtering out waste during cell growth and recirculating the good cells back into the reactor. Filtering methods such as tangential flow filtration (TFF) are well suited for this application and are commonly used.

In a typical perfusion process, fresh media is added to the tank while spent media is circulated through a filter and removed. Transmembrane pressure (TMP) is a critical variable during filtration and must be precisely maintained at a specific setpoint for the most efficient separation process. If pressure drifts, the healthy cells may not all be recirculated back to the reactor, or the waste may not be properly removed. In these cases, the filtration process will take longer or reduce yield and result in higher cost.

Valve selection for TFF can be an important decision for cost reduction. Multiple-orifice direct-sealing diaphragm valves, for instance, have been proven to provide superior filtration pressure control in TFF applications for perfusion in biopharmaceutical processes. A responsive and precise sanitary back pressure regulator will be beneficial in the role of maintaining TMP to optimize yield.

Cleaning and sterilizing cultivated meat processing equipment

Bioreactor growth tanks or cultivator tanks and associated process lines are cleaned and sterilized before the cultivated meat growth process begins. Sanitary food processes use clean-in-place (CIP) and steam-in-place (SIP) methods to eliminate food contamination and cross-product contamination.

One of the largest expenses for cultivated meat plants will be the cost of utilities, primarily used for cleaning and sterilizing. Insufficient steam control can be a costly waste of steam and energy.

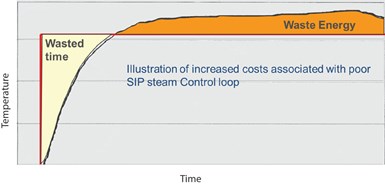

In the graph below of a standard SIP process, there are two main causes of waste: The first occurs during heat up, where the longer it takes to reach temperature, the more steam is required to continue filling the vessel and more time is wasted delaying the start of the next batch. The second occurs when the steam temperature overshoots due to improper control, resulting in wasted energy.

Graph of steam heat up and control during SIP showing where time and energy can potentially be wasted.

Photo Credit: Steriflow Valve

Higher steam temperature equates to high energy costs. By choosing a high-performing steam pressure control valve to accurately control SIP with minimal droop, process engineers can avoid wasted time and energy.

Tank blanketing for meat cultivator tanks

Once the cultivator tank is sterilized, the growth process occurs under positive pressure to avoid contamination from adventitious agents. Bioreactors benefit from an inert gas protective layer, such as nitrogen (N2), above the contents inside the tank to keep the environment sterile. The same setup can be used in cultivated meat growth tanks so the growth environment is carefully controlled to ensure the meat will grow healthy muscle and fat cells. Precise and responsive tank blanket valves can reduce cost by ensuring an optimum N2 pressure.

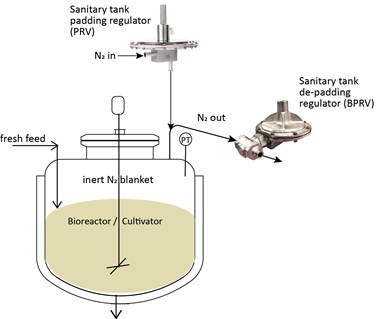

Schematic of bioreactor/cultivator tank with precision low pressure tank padding regulator and de-padding regulator working together to maintain an inert nitrogen blanket.

Photo Credit: Steriflow Food & Beverage

The example above shows how a tank padding regulator (pressure reducing valve or PRV) and a tank de-padding regulator (back pressure regulating valve or BPRV) can work together to keep an N2 blanket in the cultivator tank. Here, a sanitary tank blanketing regulator (a low-pressure PRV) is used to add nitrogen gas to the cultivator growth tank at the start of the growth process or as pressure decreases during growth. As pressure conditions change during growth, the BPRV opens to relieve excess pressure and the PRV opens to add N2 to increase the pressure. These valves work in tandem to keep the N2 padding (blanketing) at the desired setpoint.

The PRV and BPRV of choice for this process should be able to maintain very low pressure.

Looking Ahead

The cultivated meat industry is an exciting new development and needs more optimization before becoming a viable alternative to traditional farmed meat. The examples above illustrate just a few ways that proper valve selection can contribute toward the industry’s success. Working together, leaders in the industry can tackle the challenges ahead.

Photo Credit: Equilibar

Diane Jacober, MSME, is a technical marketing manager for Equilibar, and content creator for Richards Industrials, Equilibar’s parent company. She has worked as a process engineer, project engineer and technical marketing specialist for several companies in a variety of fields.

RELATED CONTENT

-

Ancient Roman Valves

The story of water supply in the ancient Roman Empire is grand.

-

Erosive Pulp & Paper Systems Require Proper Valve Selection

As new recycled paper plants are being built for the first time in decades, not only do paper companies have opportunities to grow revenue but so do service suppliers such as valve companies.

-

ValvTechnologies and Severn Form Strategic Partnership

ValvTechnologies and Severn Glocon have reached a partnership agreement that will see collaboration between two of the world’s leading engineering and manufacturing companies specializing in innovative, high-end, severe-service valves.

Unloading large gate valve.jpg;maxWidth=214)