The Pulp and Paper Industry

The pulp & paper industry has seen tough times, but the business will still be around for many decades; the product is too much in demand.

Perhaps no manufactured product plays a more significant role in everyday human activity than paper and paper products. Paper provides the means for recording, storing and disseminating most of today’s information. Even though people have extolled the coming of the paperless society, it has not yet arrived. Humans still print e-mails and other correspondence and information they get from the paperless communication channels of the computer and the Internet. And beyond that, paper is the most widely used wrapping and packaging material as well as a critical component today in everyday life. From drywall to napkins to office supplies, paper is used for many purposes, and that situation won’t change for a long, long time.

The uses and applications of paper and paper products are truly vast, and new specialty products are constantly under development. At the same time, the industry itself faces a vast array of inroads and competition from other sectors, most notably plastics and electronic media. To remain competitive in existing markets and, at the same time, be receptive to new opportunities, the paper industry today is adopting new technologies and methodologies.

PROFITABILITY

Some time back, on a tour of the pulp and paper mills in Finland with a number of North American pulp and paper people, one customer expressed amazement at the investment in new machinery and processes the Finnish companies had recently completed. This customer referred many times to the return on investment in North American pulp and paper mills, which he said was less than 3%. Why would anyone spend money for a 3% return, he questioned, when you could keep your money in the bank and get a better return. This is one of the reasons there has been very little investment in North American pulp and paper mills in recent times. The other two are stringent requirements from the Environmental Protection Agency and a buildup of stock of finished goods.

This means most growth opportunities in pulp and paper are outside North America. And the areas where companies are making money are regions nearer to the major renewable resource that runs this market—trees.

MARKET TRENDS

Globally, pulp and paper companies are still merging, buying and selling mills in an attempt to get the right mix to make a profit. This trend will probably continue until there is less paper in storerooms and/or more demand for different types of products.

Several years ago, the buzz word used most often in the industry was “Process Variability,” which meant using better process control to improve quality at the same time you use fewer raw materials and get higher production rates.

Another trend many mills adopted is “Life Cycle” analysis where a mill looks at a product to see if it can be repaired as opposed to being replaced and how many times it can be repaired to increase its life cycle. To accomplish this requires strong cooperation between the maintenance group and the procurement group to determine the best percentage cost balance of a new valve versus repair of a product. Is it 50% cost of new or upwards of 80% cost of new?

It also takes recognizing the value of a quality product in the first place. Quality means repair less often and often means less expense for that repair. The trend for some time has been toward mills repairing valves more frequently, leading more mills toward metal-seated ball and butterfly valves, which have a higher initial cost but longer life cycle. Also, some mills that traditionally used soft seats have moved to more rugged metal seats in many applications—not only for longer life but also because of higher pressure and temperatures in certain applications.

APPLICATIONS/LIMITATIONS

Beyond the usual maintenance, repair and operations issues in the paper industry are challenging applications where a valve in a mill is subjected to slurries, scaling, high velocities, high or low cycling, or where special attention is needed from the maintenance group.

Valves are often chosen by a mill based on how they can handle these challenges. In high-scaling applications, where the media sticks to the surface of the valve, for example, most plants will consider a ball valve first. This is because these valves offer full flow characteristics. Ball valves also rotate 90 degrees, and with the proper scraper seats, the media that has scaled can be wiped off the ball so the ball is clean before it gets seated. In some multi-turn valves, the scaling could sit in the bottom of the pipeline, and the valve blade cannot get through the scale to seat the valve. Cycling the valve or even partial stroking the valve can alleviate the scale buildup. As an example, green liquor (which we discuss later in this article) is a high-scaling media that can stick to the sides of pipe causing a 6-inch pipe to have a 1-inch hole because of the severity of the scaling. In cases where the scaling is extreme, cycling the valve on a weekly basis is recommended to scrape the media off the ball face.

In high-cycling applications, care must be given to packing of the valve. For example, on the echo filters in the recaustisizing area, the filters separate the impurities in white liquor. In this area, a large-diameter valve may cycle every hour because the white liquor and lime mud that are the media in this area are abrasive so that, not only do the seats get worn, but the packing tends toward wear. For this reason, a double-packed valve with live-loading is often recommended. The bottom line in any of the liquor applications, however (mills deal with green, white, black, orange, red and brown liquors), is that high-quality valves are needed and the supplier of those valves should have expertise in this specific application.

This need for expertise is one of the main problems in paper and pulp mills today. Plants have fewer people and many of those with knowledge and expertise have retired. They have to draw upon sales people, college students, engineering consultants, even the Internet for expertise. But each of these has a downside. For example, the salesman wants to sell what he has, which may not be what is best for the application. The college student has book smarts but may lack experience. Engineering consultants can be expensive; and there is no way to know if the information from the Internet is reliable. For these reasons, one of the best tools in the paper industry today is good communication between the vendor of the equipment that runs the mills and the paper mill customer.

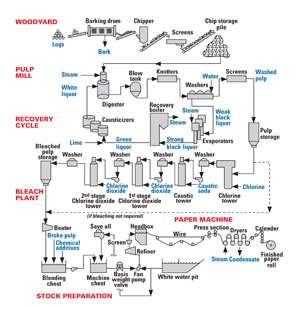

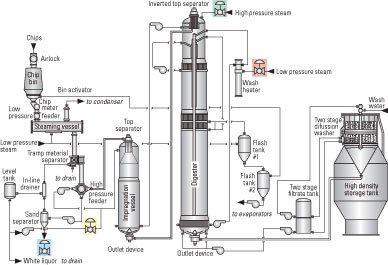

For example, when buying a capping valve, a paper mill customer needs to have a level of comfort that the company selling the equipment understands the process. A capping valve lets chips into the digester when open and isolates the digester from the atmosphere when closed. A person involved with selling capping valves needs to know how to size the capping valve correctly, whether there is potential for bridging of the chips, and what type of chip chute is required. All of this may be beyond the normal valve sales training, but it’s necessary to know the process (Figure 1).

In and around the digester, the predominant valve used is a rotary metal seated valve for both continuous and batch digesting. The differences, which are outlined in the next few paragraphs, can be seen in Figures 2 and 3.

CONTINUOUS DIGESTER

Continuous digesters use a heated, pressurized chamber into which chips and chemicals are fed. This type of digester differs from the batch digest in that chips are processed in a downward flow through zones of steadily increasing temperatures and pressure until the cooking zone is reached. The cooking liquor is also continually circulated from the digester to heat exchangers, where the liquor is reheated and reinjected into the digester. The pH of the cooking liquors is 13.5 to 14 and the operating temperatures are 240° F (116° C) at 140 psi.

A high-pressure feeder (the heart of the digester) sends the chips to the digester inlet.

A rotating helical screw pushes down chips, and steam and liquor are used to cook the chips—impregnation, heating, cooking and washing of the chips is done in one continuous operation. The chips remain in this area from two to three hours and the mass is cooled, mixed with black liquor, and mechanically conveyed or “blown” to the blow tank.

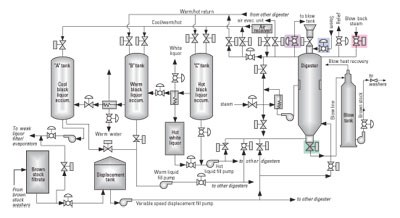

BATCH DIGESTERS

In batch cooking, the digester is filled with chips, white cooking liquor and weak black liquor. The cooking liquor, which is drawn through screens, is circulated with a pump to a heat exchanger, where the liquor is heated with steam before being returned to the digester. The chips are cooked for about three hours in this caustic atmosphere. This cooking action dissolves the bond between the cellulose fibers and the glue-like material called lignin that cements the fibers together.

After cooking, the pulp is blown through a blow valve into a blow tank where the shock of the material hitting the tank wall separates the lignin and fibers.

There is also an enhanced cooking batch digester, where the liquor goes through heat exchangers to help cook the chips without using all the steam in a standard batch digester, which means more energy efficiency and economy.

The next area of the mill that uses metal-seated valves is the recovery area. The recovery area is where chemicals from the spent cooking liquors are recovered. The reconstitution of these chemicals can form fresh cooking liquor at the same time incinerating organic residuals creates energy.

While the main focus of pulp and paper mills is on the fibers that make the paper, the mills use every part of the tree. For example, the bark goes into the bark boiler to make steam. The lignin has high BTU value so mills try to recover the lignin to burn in the recovery boiler, which also recovers many of the chemicals used in the cooking process. The recovery process is achieved through a well-defined series of steps, starting with the weak black liquor coming from the brown stock washers. The process steps are then:

- Concentration of liquor in multiple evaporators and concentrators to get to heavy black liquor

- Addition of salt cake to make up for soda loss

- Incineration of heavy black liquor in the recovery boiler

- Dissolving smelt from the boiler to form green liquor (new liquor)

- Burning of lime mud to recover lime

- Causticizing of green liquor with lime to form white liquor.

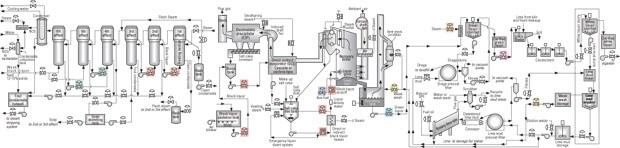

After the blow tank, the stock is washed in a brown stock washer (Figure 4). The fibers are then transferred to the stock prep area, and the wash is recovered and sent to the evaporators. Evaporators take the water out of the liquor to create high-density black liquor to burn in the recovery boiler. The evaporator island may include as many as six evaporators which are called effects—for example, the vapor in one effect becomes the steam supply in the next unit. There are four types of evaporators: rising film, falling film, cascade and cyclone.

RECOVERY BOILER

Heavy black liquor is pumped to a black liquor storage tank at the recovery boiler (Figure 5) where the liquor is mixed with salt cake—sodium sulphate—as a make-up chemical to replace the chemicals lost during washing and evaporation. The black liquor is then pumped by the nozzle pump into the boiler, where the liquor is vaporized and burned, the organics in the liquor burn as fuel, while the chemicals fall to the bottom of the boiler and flow out as smelt. The smelt flows into a dissolving tank filled with weak wash liquor from the causticizing area. The smelt is agitated and recycled to break up the molten smelt and prevent an explosion. The liquor in the dissolving tank is called green liquor.

CAUSTICIZING

Green liquor from the dissolving tank is pumped to the causticizing area (Figure 5) where it is treated with milk of lime, calcium hydroxide, to form white liquor. Because green liquor contains impurities called dregs, it must be filtered in a clarifier. The clarified green liquor is then pumped to the slaker where it is mixed with burnt lime, calcium oxide. The lime-green liquor mixture flows to two or three causticizers in a series to complete the reaction. The liquor is separated from the lime mud and becomes white liquor. The calcium carbonate precipitate is burned in the lime kiln to form calcium oxide for use in the causticizing area.

Once the process has passed through the third effect on the evaporators, metal-seated valves are normally used because the black liquor is becoming heavier and more abrasive. If the process has over half black liquor or the material is going into the concentrator, metal-seated ball valves are required.

When the fiber leaves the brown stock washer, it either goes to the paper machine or to the bleach plant, where the stock will be whitened. Many different processes are used to whiten the fibers—chlorine dioxide bleaching, ozone bleaching, oxygen bleaching, peroxide bleaching, etc. Many of these processes require higher alloy valves or valves with liners.

In regards to these higher alloy valves, a trend in the last few years is that many mills that use 316 stainless steel are complaining that steel isn’t lasting as long as the 316 stainless steel they bought years ago. This is because environmental regulations have forced many mills to close up their systems. At one time, the paper processing systems were open, and many chemicals could go downstream. Now, those processes are closed, which means that chlorides and other chemicals are building up. It also means chemical concentrations are becoming higher and higher, which is what is causing accelerated corrosion.

Because of this, valve manufacturers have had to look at sturdier materials for their valves and valve trims. For example, one popular material is AVESTA 254 SMO. For metal-seated ball valves, manufacturers are finding that the standard chrome coating is not withstanding the aggressive nature of these chemicals. HVOF (high velocity oxygen fuel) or spray and fused coating can be considered a solution, depending on the application.

Lastly, one key area for metal-seated ball valves is low-pressure shut-off. Many metal-seated ball valve manufacturers use springs to energize the ball into the seats.

Special care must be taken in specifying the testing requirements for metal-seated valves. The criteria many use is ANSI FCI 70.2, which separates the valve shut-off into classes. Most metal-seated on/off valves are class V, though some can get to class VI with special attention and lapping. The ANSI FCI 70.2 specification does not state the pressure of the test to achieve the class shut-off. Therefore, most manufacturers use the full ANSI rating of the valve.

Some manufacturers believe, however, that using the full-rated pressure makes the test less valid because the higher the pressure, the tighter the shut-off. For this reason, people seeking valves for these purposes should ensure their vendors can do a low-pressure test to meet the shut-off requirements. This low-pressure test is much harder to conduct and more valid as a result.

CONCLUSION

The pulp and paper industry has hit the doldrums, but they still require valves to keep the mills operational. With the state of the industry, mills will be looking to purchase high-quality valves from people with an idea where the valves are used and how to apply them properly. With quality products, the mills can run longer between shutdowns and repair what they have purchased instead of buying new ones every year.

Harlan Dunk has been in the valve industry for 34 years. The last 10 have been with Velan (www. velan.com), Montreal, QC, where he is the manager of several product lines. Reach him at harlan.dunk@velan.com.

RELATED CONTENT

-

The Diverse Role Valves Play in the Chemical Industry

The chemical industry is extremely diverse with more than 60,000 known products. Like all process industries, the chemical industry needs valves designed for safe, efficient and reliable process operation.

-

The Limits of Standard Manual Globe Valves for Throttling

A common practice in process services is to use manual globe valves with hand wheels for regulating flow.

-

General Considerations for Control and Choke Valves Used in Offshore Oil and Gas Production

The application of control and choke valves used in offshore oil and gas production is a very broad field and in this article, some of the main considerations for valve selection will be addressed.

Unloading large gate valve.jpg;maxWidth=214)