Paint & Coatings

A walk through a typical valve distributor’s warehouse will yield a contrasting view of either silver or black products.

#basics

In many instances, paint found on new valves is just a temporary coating, designed to delay exterior corrosion while the valve is in storage or until the final paint or coating is applied to the entire piping system after installation.

Valve standards, except for ferrous valves in waterworks service, have been nearly silent on painting and coating for new valves, referring to the paint as “manufacturer’s standard,” with newer editions of American Petroleum Institute (API) 600 adding that the paint should be a silver or aluminum color. There was one API 600 valve manufacturer that painted its ferrous valves a pleasing light blue color for several years.

While factory OEM paint may be rudimentary, end users today have elaborate painting and coating requirements that are requested for many of the valves they purchase. These requirements go far beyond the simple coat of silver or black that encases the valves as they leave the factory.

But what makes up the paint and coatings used?

Most of us know that paint often is related to a thinner. This thinner indicates more than one compound or chemical constituent is contained in the paint or coatings. Most are organic compounds made up of carbon-based components. They contain four primary elements:

- Pigments, which provide not only the coloration, but also help with corrosion resistance and the overall strength of the coating or paint mixture

- Additives, including thickeners, UV stabilizers and anti-foaming agents

- Resins, which are acrylic and epoxy that bind all the components together into a homogeneous substance

- Solvents that affect the drying time and viscosity of the paint mixture

The most basic of industrial paints are lacquers and enamels. These polymer types make up the plain vanilla of the industrial painting world. For residential and commercial applications, water-based acrylics are the primary choice. In some countries where volatile organic compound (VOC) regulations are extremely strict, waterborne acrylic latex (referred to as emulsion coatings) are used in industrial applications.

Specific coatings come in dozens of different compositions. Each end user may have many different requirements depending upon the specific exposure to weather and in-plant environmental effects. Two requirements exist for all these different coatings: the first is proper surface preparation and the second is the need for a primer coat.

Primers are the interface between the final paint or coating and the base material. They provide temporary corrosion resistance during transportation and storage. The most popular types of industrial primers are those with a corrosion-inhibiting zinc base.

SURFACE PREPARATION

Proper surface preparation is critical for the successful application of any coating. The surface may be prepared either chemically or mechanically. The chemical preparation process yields an etched surface to give more bite to the coating to be applied. Mechanical surface preparation involves removing surface imperfections by water or dry-blasting techniques. In some rare instances, old-school grinding or brushing is still employed. Different paints require different surface finishes to adhere properly.

Grease, oils, dirt and rust are removed before any coating application.

Detailed surface finish preparation procedures and requirements are specified in the Society for Protective Coatings (SSPC) documents. SSPC also publishes a host of standards and recommendations for all types of industrial painting and coating.

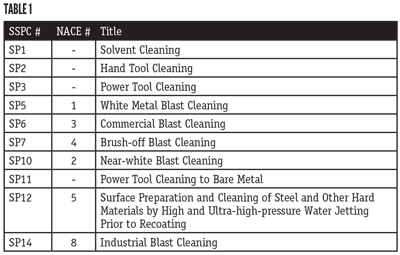

Both SSPC and NACE International (NACE) have specifications for various degrees of surface finishes for painting and coating (Table 1).

Two of the most referenced surface preparations are SSPC SP6, Commercial Blast Cleaning and SP10, Near-white Blast Cleaning.

OVERZEALOUS PREPARATION

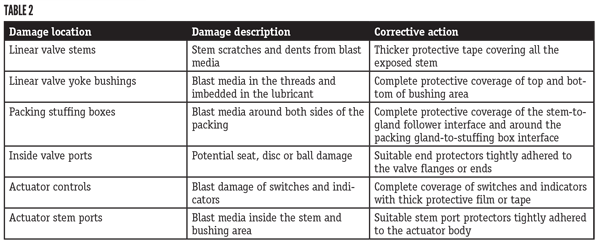

Every year thousands of valves and actuators are damaged because of improper protection during surface preparation for coating. Linear valves seem to suffer the worst damage, particularly outside screw and yoke (OS&Y) bonnet valves. Quarter-turn valves also are not immune to damage during the surface preparation stage. Some areas that are frequently damaged during surface preparation blasting include those listed in Table 2.

TYPES OF COATINGS

- Acrylic. Acrylic paints used in protective coatings are based upon either organic or water-based solvents. Waterborne acrylic latex coatings are also referred to as emulsion-based coatings. They are generally used when there are VOC release concerns during the coating process.

- Alkyds. Alkyds are fatty-acid modified polyester resins. Most of the alkyd-based paints dry from a chemical reaction between the fatty acids and the air.

- Epoxy. Epoxy coatings are two-part resins that, when combined, form a chemical reaction between the epoxy and the hardener that cures the epoxy. Epoxies are generally very tough, corrosion-resistant coatings, but their pot-life is short. Most epoxy coatings also have poor UV stability.

- Polyurethane. Like most epoxies, polyurethanes are two-part coatings. They exhibit a smooth finish often used as a final coat over epoxies and zinc primers.

THE RIGHT COATING

The first question that needs to be answered when a coating is being selected is “why is the equipment being coated?” In piping systems and valves, the answer is usually for corrosion resistance rather than overall attractiveness.

The second, and most important question concerns what the coating will be exposed to with considerations such as:

- Are chemical fumes close by?

- What is the operating temperature?

- Are chemical splashes or spills likely?

- Will the coating be covered with insulating materials?

- Will the coating be cleaned, and what cleaning process and chemicals will be employed in the cleaning process?

- Will the coating be applied over an existing coating?

Other questions regarding proper selection include: Where will the coating be applied, in the shop or in the field; and what is the expected service life of the coating?

A last question is: What is the budget for the coating? This question quite often trumps some of the other questions, depending upon budget, life expectancy and other considerations.

REAL-WORLD EXAMPLES

Coating specifications consist of three parts that constitute the complete coating process. They are: 1) pretreatment and surface preparation, 2) paint or coating application and 3) paint or coating curing. A paint or coating is transformed into a solid paint film through the curing process. This curing may occur at room temperature or in an oven.

The paint or coating requirements of an end user are different from those of the valve manufacturer. Here are some sample paint/coating specifications from both those entities:

Petro-chemical plant, general piping system, including valves:

- Surface preparation: SP10

- First coat: Phenolic epoxy

- Second coat: Phenolic epoxy

Offshore facility, process equipment piping:

- Surface preparation: SP5

- First coat: Solvent-based inorganic zinc

- Second coat: Silicone acrylic

Ball valve manufacturer, standard finish:

- Surface preparation: SP3 (equal)

- First coat: Phenol-modified alkyd resin paint

- Second coat: Synthetic resin aluminum paint

Gate, globe & check valve manufacturer:

- Surface preparation: SP6 or SP3

- Undercoat: Phosphate

- First coat: Modified alkyd resin primer

- Second coat: Silicone-modified alkyd resin paint

Compact gate, globe and check valves, designed in accordance with API 602, are usually shipped from the factory without paint. However, they normally have a corrosion-resistant (e.g. phosphate) coating to stave off corrosion until they are installed, and the piping system receives its final coating.

The development of dozens of paint and coating choices has helped to increase the lifespan of installed valves. This means that potential leaks caused by exterior corrosion are all but eliminated. Also, with the ongoing significant emphasis on fugitive emissions, one less leakage worry is certainly a good thing.

GREG JOHNSON is president of United Valve (www.unitedvalve.com) in Houston. He is a contributing editor to VALVE Magazine, a past chairman of the Valve Repair Council and a current VRC board member. He also serves as chairman of the VMA Communications Committee, is a founding member of the VMA Education & Training Committee and is past president of the Manufacturers Standardization Society. Reach him at greg1950@unitedvalve.com.

RELATED CONTENT

-

Ball Valve Basics

Welcome to the first in a series of Valve Basics articles, each focused on a major product type and written especially for newcomers to the industries that use and make valves and related products.

-

The Future of Valve Manufacturing is Already Here

Companies in the valve and control products industry are responding to a confluence of forces that are changing the landscape of manufacturing — automation, agility and digitalization to name a few.

-

Understanding Torque for Quarter-Turn Valves

Valve manufacturers publish torques for their products so that actuation and mounting hardware can be properly selected.

Unloading large gate valve.jpg;maxWidth=214)