Wireless Technology Optimizes Production in Mining Operation

Natural Soda operates seven production well pairs in Colorado to produce saturated nahcolite brine for manufacturing sodium bicarbonate (baking soda).

Mining nahcolite requires very careful monitoring of temperature, pressure and flow to not only optimize production performance—but also to mine the product sustainably and protect the freshwater aquifer.

#pressure-relief #automation

Protecting the aquifer

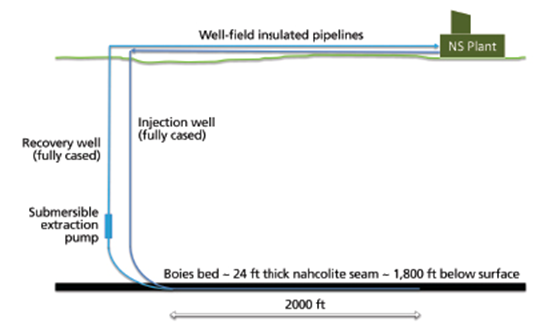

Natural Soda recovers sodium bicarbonate using a process known as solution mining. This involves pumping heated water approximately 1,900 feet underground (Figure 1) to dissolve the underlying nahcolite beds. The water, now saturated with sodium bicarbonate, is then returned to the surface by a submersible pump.

A key element of the BLM mine plan is controlling the pressure of the saline aquifer (referred to as the dissolution surface aquifer) immediately above the mining zone. The mine plan specifies that the pressure in this aquifer must stay below the pressure of the upper freshwater aquifers to eliminate the potential of cross contamination between the aquifers.

Continuous monitoring and adjustment of injection and recovery flow, temperature and pressure allow us to maintain full compliance with this requirement, and to collect the necessary historical data for proper record keeping and required regulatory submissions.

Upgrading the system

The original Natural Soda facility was built in 1990 with the capacity to produce 60,000 tons per annum (tpa) of feed-grade product to be sold domestically. In March 2013, the company completed construction of an additional production train, increasing annual production from 125,000 tpa to 250,000 tpa, making Natural Soda the second-largest producer of sodium bicarbonate in the U.S.

In addition to the new train, the expansion included additional packaging and distribution infrastructure, supporting Natural Soda’s move to provide sodium bicarbonate to multiple markets, such as the highly competitive food and personal care markets around the globe, rather than just focusing on the domestic animal feed market.

The number of well pads where solution mining takes place increases in proportion with production, as do reporting and technology requirements, including the need to acquire data from the additional well pads.

At Natural Soda, the existing wells have WirelessHART capability, communicating to an [wireless gateway] that is hardwired via an RS-232 serial link to the distributed control system (DCS) in the production plant. The DCS monitors inputs from the wireless transmitters at each well pad and sends valve control instructions to each well pad’s programmable logic controller (PLC) via a radio link, separate and different from the WirelessHART network (Figure 2).

Serial data is sent to the PLCs using a GE MDS 900 radio master and MDS 900 radios as slaves at each well pad. The radios transfer data back and forth between PLCs in the field and the control room via a hardwired RS-232 data link between the radio master and the DCS.

The bottleneck was our use of a two-port RS-232 serial I/O card installed at the DCS. Data from the wireless gateway used port #2, and the radio master used port #1. Serial data is limited to 16 data sets per port. At the time of the expansion, port #1 was at 15 data sets, and port #2 was being used by the wireless gateway. To accommodate more wells, we needed to free port #2 so we could send commands to the additional PLCs.

That meant measurement data from new wells might have to be hardwired from the field to the DCS. The distances involved made this an expensive proposition, since some of the wells were more than a mile from the production plant. Installing wire and conduit the entire distance from the well fields to the DCS would have cost $80,000–$90,000, and we were hesitant to proceed with this installation due to the environmental impact it would have on the flora and fauna.

Instead, we installed a wireless I/O card (WIOC). The WIOC was installed in one of the DCS racks. It receives WirelessHART data and transfers it to the DCS. The cost of installing the WIOC was a fraction of the price of hard wiring, and it could be installed within our required timeline, saving time and approximately $70,000.

Before the expansion, we had 30 wireless devices on five wells connected to the wireless gateway. From 2013 to 2016, new wells were brought on line, bringing the total to 48 wireless devices. We plan to have 60 wireless devices on 10 wells operating by the fall of 2017, thus doubling the size of the original system at a minimal cost.

The expansion also included a new controller in the DCS interfacing directly with the WIOC. It sends valve control and other data to the PLCs via the serial radio link.

Each well pad includes a steam injection well and a recovery well for pumping out the nahcolite brine. Instrumentation at each injection wellhead includes a wireless temperature transmitter, a wireless pressure transmitter and a magmeter with a wireless adapter (Figure 3). A wireless output is used to control the injection valve. Instrumentation at the recovery wellhead includes the same type of wireless flow, temperature and pressure transmitters.

Each PLC also has hardwired connections from analog outputs to control valves, analog inputs from flowmeters, and discrete I/O for control of remote water wells.

Results

The most important result of using WirelessHART flow, pressure, and temperature transmitters at the well pads is that Natural Soda can confidently operate and deliver expected results within the parameters of the BLM mine plan with no leakage into the freshwater aquifer.

In addition, maintenance costs have been reduced by half because the system has no fuses or power supplies, and no wires. WirelessHART status and diagnostic information indicates if any transmitter has a problem, and the system alerts the operators accordingly. If a problem does occur with any transmitter, technicians can go right to the device and troubleshoot with a HART communicator. A laptop is not required in the field for maintenance.

Future plans call for installation of asset management software to enhance troubleshooting, including the installation of pump and motor health management hardware and software.

Raymond Pfister is maintenance I/E lead at Natural Soda. This article appeared in its original form in the 2017 March/April issue of InTech Magazine, © 2017. It is excerpted and reprinted with permission from the International Society of Automation (ISA).

RELATED CONTENT

-

Valve Basics: Electric Actuator Controls

Electric valve actuators control the opening and closing of valves. With a motor drive that provides torque to operate the valve, these actuators are frequently used on multi-turn valves such as gate or globe and also on ball, plug and other quarter-turn valves.

-

Solenoid Valves: Direct Acting vs. Pilot-Operated

While presenting in a recent VMA Valve Basics 101 Course in Houston, I found myself in a familiar role: explaining solenoid valves (SOVs) to attendees. (I work with solenoids so much that one VMA member at that conference joked that I needed to be wearing an I Heart Solenoids t-shirt). During the hands-on “petting zoo” portion of the program, which involves smaller groups of attendees, one of the most frequently asked questions I get from people came up: What’s the difference between direct-acting and pilot-operated SOVs, and how do we make a choice?

-

Rigging and Lifting of Large Valves

This article outlines the challenges of lifting large valve assemblies weighing several tons and illustrates the industrial rigging equipment and lifting operations typically used for these valves.

Unloading large gate valve.jpg;maxWidth=214)