Latest Launches

Valmet Launches DNAe, Next-Gen Distributed Control System

Valmet introduced its next-generation distributed control system (DCS), the Valmet DNAe.

#actuators #controls

Valmet Launches DNAe, Next-Gen Distributed Control System

Valmet introduced its next-generation distributed control system (DCS), the Valmet DNAe. The fully web-based process control system comes with a new cybersecurity system architecture, control software and hardware, engineering and analytics tools, helping customers improve efficiency, productivity, sustainability and safety of their operations.

Designed to support the work of all process automation user groups, Valmet DNAe was developed with a design philosophy to empower people to perform and collaborate better across the organization. The system provides a common user interface for controls, analytics, configuration and maintenance. Advanced analytics tools enable turning real-time and historical data into actionable insights.

The system empowers users to seamlessly run industrial applications on-premises, at the edge server or in the cloud. It features a scalable redundant data platform, granting easy and controlled access to all data. The system architecture is cybersecure by design, with role-based access control, authentication, audit trail and encryption mechanisms for proactive prevention of cyber threats.

valmet.com

Self-Calibrating Electric Actuator from Emerson Fisher

Emerson has introduced the Fisher Easy-Drive 200R Electric Actuator for use on Fisher butterfly and ball valves. The actuator performs accurately and reliably under the extreme conditions found in many heavy industries, particularly oil and gas installations in cold remote locations. These actuator/valve assemblies increase uptime, improve performance and reduce the risk of emissions posed by gas-operated systems locations.

The actuator is easy to install and calibrate using the easy-Drive Configurator Software, provided free of charge with the actuator. Its operates on 11 to 30 VDC power and consumes less than 0.4 W when in the holding position mode, making it suitable for use in applications without available utility power. Operating in temperatures as low as -40°F (-40°C), it eliminates the need for a space heater in all but the most extreme temperature applications.

The 200R is an extension of the easy-Drive actuator portfolio, which also includes actuator options for both globe and rotary valves. To learn more, please visit the company's website. emerson.com

Groth Corp. Announces New Pilot-Operated Relief Valve

The Groth Model 16F pilot-operated relief valve offers reliable low-pressure protection in compliance with API 2000 standards for pilot-operated relief valves. Its design prevents fugitive emissions and conserves stored product.

The Model 16F pilot-operated relief valve employs an optional film seat-sealing technology for superior sealing and offers flexibility regarding snap or modulating action.

Features include a main valve that remains tight to set pressure; full open at 10% overpressure; modulating action conserves product because valve opening is proportional to overpressure; soft seats seal tight to conserve product and minimize valve wear, improving reliability; high flow rates minimize pressure drop during relief events. The valve is suited for cryogenic applications. grothcorp.com

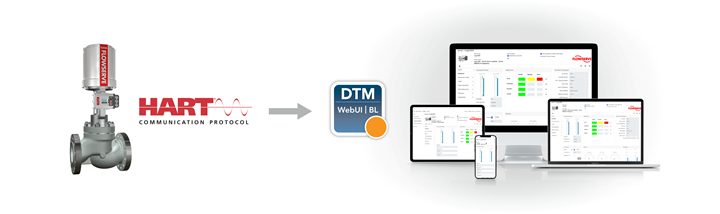

Flowserve Receives First FDT 2.0 DTM Certification from FDT Group

FDT Group, an international, nonprofit industry association supporting the evolution of FDT technology for industrial device management, announced certification of its first device-specific DTM based on the latest FDT 3.0 standard supporting the HART protocol from Flowserve Corp. The newest certified Logix 3820 Series DTM is deployable using Flowserve positioners supporting HART 6/7 and tackling flow control challenges designed for modern IIoT architectures.

FDT DTM certification to the FDT 3.0 specification and webUI is a process with rigorous compliance testing using dtmINSPECTOR5, ensuring the viability of the states of the DTM. It features correct installation, de-installation and multiuser environment capability; mandatory and optional user interface functionality and robustness; network scanning communication performance, and the ability to import and export the topology; and an audit trail capability.

Users can use secure and seamless data exchange/interrogation from the sensor to the cloud, and achieve new levels of information technology (IT) and operational technology (OT) integration. flowserve.com

Comprehensive Automation Platform Empowers Action from Plant to Enterprise

Emerson is evolving its DeltaV brand into the DeltaV Automation Platform. The newly expanded automation platform will include supervisory control and data acquisition (SCADA) systems, manufacturing execution systems (MES) and operations management software alongside the distributed control (DCS) and safety systems (SIS), and other technologies that have been part of the brand for decades. The evolution builds a more comprehensive automation platform to make it easier for users to deliver smarter, safer, more optimized and more sustainable operations.

The comprehensive nature of the new DeltaV Automation Platform will empower users to move away from “plant-by-plant” strategies to “site-by-site” or even enterprise automation solutions — the more advanced, integrated automation strategies that are increasingly necessary to compete in a complex global marketplace.

All solutions in the DeltaV Automation Platform will be seamlessly supported through the Guardian digital customer experience. Users will have a single point of access to Guardian’s digital tools and subscriptions for all their solutions, providing easy access to real-time monitoring, in-depth analytics and actionable insights. Emerson.com

RELATED CONTENT

-

How the EPA's Emissions Rule May Impact Actuator Choices

The move toward net zero emissions by 2050 was just released as part of the COP28 meeting in Dubai.

-

Understanding Torque for Quarter-Turn Valves

Valve manufacturers publish torques for their products so that actuation and mounting hardware can be properly selected.

-

Standards for Actuator/Gearbox Flanges

“Many variations in valve and actuator dimensions and characteristics have come into play especially now that we have worldwide vendors,” said Paul Souza, training manager at AUMA Actuators in a presentation at the Valve Manufacturers Association Virtual Valve Forum in November 2020.

Unloading large gate valve.jpg;maxWidth=214)