The content of American Society of Mechanical Engineers (ASME) Standard B16.34 is essential to those who deal with flanged, threaded, and welded-end valves. The standard covers pressure-temperature ratings, materials, marking, and other characteristics of cast, forged, and fabricated valves.

To help understand the standard, Mitchell Anderson, technical director for butterfly valves and engineering quality at Bray International Inc., presented a VMA Webinar overview for purchasers, specifiers and users of valves. A few highlights of what he covered are included here.

Anderson began by explaining the different types of documents that apply to valves and their applications. Codes provide sets of rules and regulations. Standards provide specifications for how equipment is designed and how to assure quality. Recommended practices provide guidelines and good engineering practices.

WHAT B16.34 COVERS

Because it’s a standard, B16.34 “focuses on design and quality. You’ll see it doesn’t address applications,” Anderson pointed out.

The ASME B16.34 standard also is referenced in many other standards and codes put out by other organizations, he added.

ASME B16.34 includes the following sections:

- Scope

- Pressure-Temperature Ratings

- Pipe Size

- Marking

- Materials

- Dimensions

- Pressure Testing

- Special Class Valves

- Mandatory Appendices

- Non-Mandatory Appendices

SCOPE

Scope is the first consideration when reviewing any code, standard or recommended practice, Anderson said, because people have to understand this section to see if what they’re trying to evaluate is covered by a particular standard. For this reason, he considers this section one of the most important parts of any standard.

The scope section covers considerations such as pressure-temperature ratings, dimensions, tolerances, materials, nondestructive examination requirements, testing, and marking for certain types of valves made from steel, nickel-based alloys and some other materials listed. Additional requirements included within the scope section address:

- Pressure and temperature at the time of purchase, manufacture and installation

- User accountability

- Selection of valve types and material service conditions

- Valve class and pipe size (NPS & DN) designations

- Cryogenic valves

MATERIALS

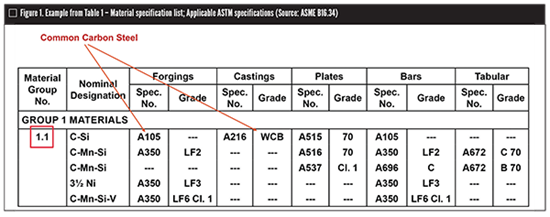

The materials section is divided into groups of materials types and sub-groups of similar materials with common pressure-temperature ratings. Anderson referred to Table 1 in the standard to explain those groupings. Group 1 is carbon and low-alloy steels; Group 2 is stainless and duplex materials; and Group 3 is nickel and nickel alloys. Under these categories are 49 sub-groups.

Figure 1 shows the American Society for Testing and Materials (ASTM) specification and grade for common carbon steel. This table is one of the most important aspects of the standard, Anderson said, and it can be hard to understand. He explained that, in the table, the common carbon steel materials used for valves are forged material to ASTM A105 and the cast material to ASTM 216 grade WCB.

PRESSURE-TEMPERATURE RATINGS

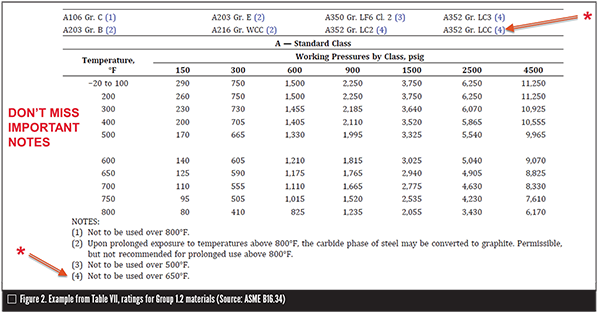

B16.34 uses metric units with additional tables and information in U.S. units. Tables 2 (metric) and VII (U.S. customary units) give pressure-temperature ratings for each listed material.

Figure 2 shows an example of pressure-temperature ratings for materials in Group 1.2. The valve design temperature is selected from the left column and the valve pressure class is listed above. Those two comparisons on the chart show the pressure-temperature rating. For example, if a valve is made from A106 Grade C and designed to Class 150, at an operating temperature of 200°F, the pressure-temperature rating is 260 psig. If its operating temperature is 750°F, the pressure-temperature rating is 95 psig.

The table is set up by groups of similar materials, but even within a group, variations and limitations to use exist, especially regarding operating temperatures. Figure 2 shows some of those variations in the form of important notes to consider. For example, for A352 Grade LCC, note 4 indicates that it should not be used over 650°F. It is critical that users pay close attention to those notes, Anderson said. This is because of situations such as this: at first glance, since the table goes up to 800°F, a user might assume all the materials could be used at that temperature, but the note warns that some of the materials must be limited to 650°F.

“People may be tripped up by notes and references,” Anderson said. But they are there to point out vital information. They may seem a nuisance because they lead down a long trail, but that trail is very important for knowing a material’s limitations, he said.

MARKING

The ASME B16.34 marking specification complies with Manufacturers Standardization Society (MSS) SP-25 standard-marking system for valves, fittings, flanges and unions.

The minimum requirements for marking valves are:

- Name of manufacturer

- Materials of body, bonnets, cover plates

- Pressure rating

- Temperature

- Size

In addition, if a valve complies with B16.34, it can be stamped “B16.34” on the nameplate.

STANDARDS CHANGING OVER TIME

As with other standards, B16.34 is periodically updated and improved. The most recent revision was in 2017.

Anderson warned webinar attendees to be aware that change is part of the process and to try to keep up to date. When a change is made to one standard, changes may also apply to other referenced standards or codes. Each new version refers specifically to what changes have been made.

Anderson gave an example of a change in the standard and how it could lead to confusion:

Material group 2.8 is listed for duplex stainless materials. Several years ago some of the ASTM specs for duplex materials were changed. They were originally listed as A351 then became ASTM 995. This has caused some confusion, Anderson explained. Most people when they think of duplex materials think of grade 4A or 6A. But currently, for castings, grade 4A is listed as CD3MN and 6A is listed as CD3MWCuN.

Anderson pointed out that though it is sometimes difficult to keep track of all that happens with these standards, understanding them, including B16.34, is critical to providing valves that will operate successfully in the environment where they’re put into action.

BARBARA DONOHUE is Web editor at VALVE Magazine. Reach her at bdonohue@vma.org.

RELATED CONTENT

-

Valves in Space

All of these valves need to be built to precise fits and finishes and to stringent performance requirements because “On a spacecraft, everything has got to work. If it breaks, you’re done.”

-

New Requirements for Actuator Sizing

After decades of confusion, the American Water Works Association has created new standards for actuator sizing that clear up some of the confusion and also provide guidance on where safety factors need to be applied.

-

Standards for Actuator/Gearbox Flanges

“Many variations in valve and actuator dimensions and characteristics have come into play especially now that we have worldwide vendors,” said Paul Souza, training manager at AUMA Actuators in a presentation at the Valve Manufacturers Association Virtual Valve Forum in November 2020.

Unloading large gate valve.jpg;maxWidth=214)