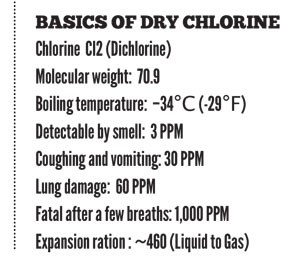

Dry chlorine gas is found within chlorine production, storage and transfer facilities, as well as in downstream processes such as production of vinyl chloride monomer (used in making polymer polyvinyl chloride) or phosgene (used in applications such as pharmaceuticals and organic compounds). Dry chlorine is generally understood to have less than 150 parts per million (PPM) water containment. 1 Moisture contamination in any of these dry chlorine service areas, however, can result in the formation of dendrites, crystal-like masses that can cause problems.

For example, research shows that dendrite formation on critical sealing surfaces, such as valve seats and packings exposed to extremely harsh operating conditions, leads to a significant increase in potential leak paths because of erosion of seal surfaces that come into contact with the dendrites. Dendrites can also form on contacting or sliding surfaces, causing valves to freeze or to become abrasive to the soft seat, which can lead to severe seat damage. In fact, any amount of moisture can lead to dendrite formation and rapid corrosion of moving valve parts.

A recent collaboration between valve manufacturers and end-users has led to a clearer understanding of the factors that cause valve failure under these circumstances and factors that can increase the service life of those valves. As part of that collaboration, researchers investigated construction materials that could combat moisture contamination and provide enhanced performance in harsh operating conditions, looking at each component of the valve for dendrite susceptibility. Suitable materials were identified, leading to designs that incorporate the appropriate combination of superalloys and stainless steel to allow for a cost-effective solution to these issues.

This article discusses the relationship between dendrite formation and valve life, and provides an overview of shortcomings that are now being overcome with these new designs and materials. Coincidentally, the improvements in design that resulted, combined with best practices for specifying features, has contributed to lower total life-cycle costs in the critical applications in dry chlorine services.

THE ISSUES INVOLVED

To understand the newer solutions and how they were derived, it is important to look at critical valve performance and maintenance issues that end-users encounter in applications involving dry chlorine. Understanding the factors that can contribute to valve failure enables valve manufacturers to make corresponding design improvements, and the end-user can use this knowledge to extend valve service life.

By working through both typical and more unusual critical pain points, it became evident that dendrites often formed on the surface of Monel discs, causing damage to the soft seats. When such crystals form on frictional surfaces, they cause binding and seizing of mating parts. An example is simple components such as disc spacers that keep the disc centered. The shaft turns inside the bearings and packing so any crystal formation quickly deteriorates these critical components. When these crystals form on hard surfaces that make contact with soft seals, they erode the seals (working like sandpaper).

Furthermore, while Monel performs well in dry chlorine service (when temperatures stay high enough to preserve chlorine’s “dry” form), any amount of moisture can lead to rapid corrosion of moving parts. For these two reasons, engineers settled on HastelloyC as the preferred material for disc and stem construction.

For the valve body, CF8M stainless steel has been identified as the new standard, but all other valve components (pin, gland, bolts, etc.) were also studied individually to determine the optimal choice of material. Using Hastelloy for key parts enables the valve to tolerate moisture. Using CF8M stainless steel for the body, meanwhile, also makes the exterior visibly cleaner and provides visual confirmation that the device is robust.2

DESIGN REALIZATION

Pamphlet 6 of the Chlorine Institute (page 5 of the May 2005 edition), recommends the use of carbon steel for piping for handling dry chlorine. Monel bodies and internals are recommended for dry chlorine, but on page 20, it suggests that consideration be given to materials suited for both wet and dry applications if there is a chance that moisture contamination could be present. For wet chlorine, HastelloyC internals are specified by The Chlorine Institute (note that dry chlorine can become “wet” through moisture contamination, or by sufficiently reduced temperatures).

Research indicates that even in dry chlorine service, systems are prone to moisture contamination during installation or whenever connections are made. Such contamination reacts with the chlorine and forms hard, microscopic metallic chloride crystals on metal surfaces. This occurs even on Monel surfaces, which are considered acceptable with perfectly dry chlorine.

WCB valve bodies are normally recommended for dry chlorine since stainless steel is susceptible to chloride stress cracking. CF8M bodies have demonstrated exceptional endurance in corrosive environments, while being structurally resilient against stress-cracking.

End users also showed interest in valves featuring live-loading, double-packing with monitoring ports and Inconel spring (Belleville washers). Ideally, the packing gland is made from HastelloyC to prevent freezing in the packing bore, which would disable live loading. The packing gland is a simple part on the outside of a valve that might not appear imperiled by possible contamination. Experience indicates, however, that it can be exposed to considerable moisture and minute traces of chlorine vapor emanating or permeating from the system, often causing the gland to seize. Once this occurs, it no longer serves its function of pressurizing the packing, and leakage may result.

Because of these risks, Alloy 20 bolting can be used for packing gland studs and nuts to minimize corrosion on these stressed parts. At the same time, this mitigates stress cracking concerns that arise when stainless steel is used.

A lantern ring between the series of packing allows leakage from the flow path to accumulate in an area adjacent to the second packing. A small sampling valve can be threaded to a monitoring port channeled to this area so it can be periodically checked for early signs of weakening. The lantern ring should be made from HastelloyC to ensure long term operation.

Chlorine systems often encounter rust or scale so valve seats must be impurity-tolerant. Molecularly enhanced PTFE (TFM) has the disadvantage of performing poorly at low temperatures whereas the R-PTFE ensures valves perform well during temperature cycling and in cold environments.

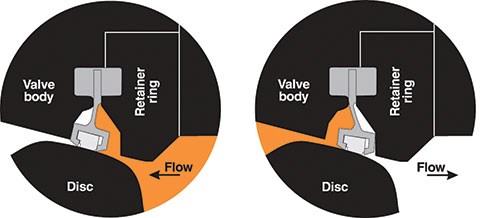

Systems often require bidirectional sealing as well as the ability to be used in end-of-line service with pressure contained behind a closed valve without the concern of which side will remain exposed to the medium being processed (which is accompanied by pressure from the piping system).

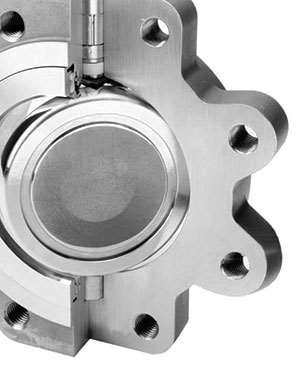

Because minimizing the potential for leak paths is essential in controlling fugitive emissions, using a closed bottom design is a good choice for inhibiting leakage that might occur if the shaft bore protruded through the bottom of the valve. This is the acknowledged best design for valves 12 inches and under. For larger valves, where it is not practical to bore the bottom shaft hole from the top of the valve, a bolted plate with a static PTFE seal is preferred over a threaded plug because a threaded plug tends to grab a seal and twist it during assembly.

CONCLUSION

With the foregoing realities in mind, valve manufacturers are either developing solutions or have already succeeded. The culmination of those efforts is a valve made with materials designed to withstand and be impervious to the effects of dendrite formation. Such is the case with some high-performance butterfly valves, which have incorporated the advances mentioned here in efforts to meet the needs of dry chlorine service. Such valves represent a breakthrough in design, as they specifically address the requirement of preventing valve damage from both moisture contamination and abrasion or erosion.

Bert Elfers is global business manager, butterfly valves, Crane ChemPharma Flow Solutions, Xomox (www.xomox.com). Reach him at befers@xomox.com.

FOOTNOTES:

1 The qualifying reading may not always be 150 PPM because chlorine at this and lower readings can become “wet” in sufficiently cool or cold conditions.

2 For reference about recommended materials for valve components, please see the Valve Materials Selection Guide provided by The Chlorine Institute: www.cl2.com/index.php/.../139-pamphlet-6-edition-15-may-2005 table 4.8).

REFERENCES

- The Chlorine Institute, Inc. Pamphlet 6 – Piping Systems for Dry Chlorine (Edition 15)

- Xomox Manufacturing Control Manual – Level III Cleanliness Requirements: Chlorine, Food, Std. Oxygen, and Vacuum Service Valves

RELATED CONTENT

-

Understanding Torque for Quarter-Turn Valves

Valve manufacturers publish torques for their products so that actuation and mounting hardware can be properly selected.

-

Back to Basics: Globe Valves

There are many applications where the globe valve outshines other designs, so the future is still bright for these long-time favorites of the flow control industry.

-

The Misunderstood Check Valve

Too often this valve is unjustly blamed when problems occur, but the real culprit is its use in the wrong applications.

Unloading large gate valve.jpg;maxWidth=214)