FEL: The Preferred Phase for Valve Technical Definition

A typical oil and gas capital project cycle consists of a process of structured stage gates that ensure activities are processed or completed in a logical sequence.

This stage gate process starts with Front End Engineering Design (FEED) (Figure 1), in which Front End Loading (FEL) activities are performed before the project is sanctioned or authorized. FEL is essentially pre-project planning, starting with conceptual studies, scope development, and evaluation of project feasibility in terms of engineering and commercial aspects to determine the overall balance of risk to reward.

During FEL, when the ability to influence design changes is relatively high and the cost of changes is relatively low, discovery and understanding of strategic information can be used to reduce risk and make commitments to resources that will maximize the potential for project success. Some project teams use information gathered from FEED deliverables to facilitate final investment decision making.

FRONT END LOADING

Well-executed FEL is increasingly important today in light of the current environment of increasing project complexity, broader scope of work and schedule-driven contracting strategies. Intensive resource loading during the early stages of a project will help to develop a technical foundation, which may include the project design basis, concept definitions and defining documents. Potential challenges are identified and resolved up front, ensuring a project can be executed smoothly during the stages of detailed engineering, construction and commissioning.

A project with compressed FEED could face challenges in detailed engineering and execution because it lacks design maturity caused by limited time available to perform full FEL. Problems that could surface from this compression include incomplete key project defining documents and undefined key project design parameters and scope. These, in turn, can lead to cost overrun and delays in overall project schedules.

FEL IN OIL & GAS

FEL generally is applied to a project’s facility and system design. Because of this, it may not be adequately implemented at the time of valve technical definition. The reason this happens might be project schedule limitations and resources that push valve technical definition to the detailed engineering stage. In such cases, the focus is often on completing project key FEED deliverables to meet contractual obligations, and most of the time, valve development is limited because that development is perceived as having minimal impact on the project. The project team may not realize that, although the short-term objectives are met in FEED, addressing valve technical issues at later stages can be detrimental to the project in the long run in terms of higher costs. Early stage interventions, on the other hand, can influence valve costs greatly, as illustrated in Figure 2.

Valve engineering is commonly performed as part of the Detailed Engineering phase; however, considerable cost would be avoided if this occurred during the FEED phase.

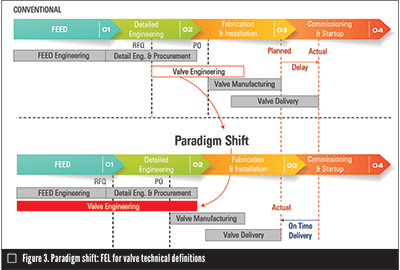

PARADIGM SHIFT FOR VALVE FEL

Introducing a paradigm shift (Figure 3), where FEL includes valve technical definition, places valve core engineering activities back to the front end. This shift can influence more timely major valve engineering decisions. It moves valve engineering changes from the traditional approach of carrying them out in the detailed engineering stage to a new approach of introducing them in the FEED stage. This paradigm shift can advance valve technical definitions to a place before the detailed engineering phase, thereby achieving a well-defined and clean valve technical request for quotation (RFQ) package. This, in turn, reduces cost overrun risk and schedule delays for the overall project.

THE VALUE OF VALVE FEL

Valve technical definition during FEED is also crucial for reducing the potential for a large amount of rework as a project moves towards the detailed engineering stage.

By leveraging valve FEL, value can be maximized by:

- Achieving valve engineering and design optimization fit for the application (fit-for-application)

- Injecting industry best practices and lessons learned

- Achieving compliance and standardization

- Optimizing costs and reducing schedule risk

FIT-FOR-APPLICATION/DESIGN OPTIMIZATION

Choosing the proper valve for the application has always been the key focus of procurement philosophy. This fit-for-application valve selection and design optimization also are critical for meeting overall expectations for safety, operability and availability.

To achieve these project expectations, valve requirements should undergo review to ensure that project design intent and functional expectations are met. Design intent consideration means specified valves go through compatibility evaluation to ensure they can meet the conditions to which they will be exposed. For functional requirements, valves would undergo process evaluation to see if they meet expected operation and performance needs.

Valves that do not meet project design and operational considerations can impact project integrity through conditions such as seat and external leakage, premature material corrosion and erosion, and more. They also can impair process operability and result in ongoing system reliability and loss of efficiency.

BEST PRACTICES AND LESSONS LEARNED

Another key element for achieving complete valve technical definition is adopting applicable lessons learned and industry best practices during the FEED stage. A highly qualified valve FEL team will have access to a wide variety of applications, cross-industry resources and best-in-class technology data on materials, designs and philosophies. This access can be leveraged into a near-real-time continuous-process improvement knowledge base. This deters mistakes, repeats of valve challenges encountered in the past, as well as more recent and emerging technical challenges. This real-time process improvement in a rapidly changing application and cost environment reduces risk, expense and schedule overruns.

In practice, these process changes can be applied throughout all project execution phases. By setting fundamental guidelines early, the quality of project deliverables, the maturity of the valve technical definition and the project’s schedule are all improved with less recycling of the ever-increasing volume of information. This in turn reduces administrative resource requirements and the possibility of sliding schedules. It also allows for improved future information rather than correction of past errors. Many areas can reap benefits from application of these practices such as valve engineering, quality control (testing and inspection), manufacturing operations and documentation.

As industry continues to evolve and advance, it is vital that project governance is committed to developing, capturing and maintaining the best information and practices as guidance for making sound decisions.

COMPLIANCE AND STANDARDIZATION

Besides complying with corporate and industrial valve standards, project-specific valve requirement compliance is vital for meeting facility design intent. Because of increased project complexity and contracting strategy, engineering procurement contractors (EPCs) tend to adopt individualized practices to meet contractual commitments. These practices often are based on lessons learned from unique sets of circumstances as well as personal preferences among lead EPC managers. However, those practices may not apply with the specific project under contract—they may misalign with owner requirements or cause over- or under-specification of valves. The convergence of EPC practices with owner requirements also can lead to inconsistent, subjective interpretation of project specifications that result in time-consuming bid clarifications as well as specification deviation.

Ultimately, when valve technical definition lacks maturity, it can lead to procurement of noncompliant valves. By obtaining valve manufacturers and subject matter expert input during the FEED stage (before the RFQ phase), compliance challenges can be identified and resolved to enhance valve quality.

In addition to compliance challenges, facility development can encounter standardization challenges, especially for a project with multiple EPCs. In most cases, this means a hodgepodge of valves and spares would be procured. This wide variety of valves creates intensive operations and maintenance (O&M) management and excessive holding of spares. Standardization is best achieved in the early project stages by aligning valve O&M philosophy with project valve selection and procurement strategy.

COST OPTIMIZATION/REDUCED SCHEDULE RISK

Shorter engineering cycles and a compressed FEED phase can mean that most of the project execution will tend towards prioritizing major processing equipment over valves. Meanwhile, a lack of focus on valve engineering in the early phases of a project can result in overlooked valve cost optimization and identification of schedule risks.

Valve cost optimization is commonly achieved through fit-for-application selection of valve types, cost-effective material selection and purpose-driven nondestructive examination and testing. Exercising valve engineering in the early phases maximizes cost optimization results.

Valve schedule risks can be alleviated by identifying valves with long lead times (i.e., valves that require prototype development and testing) in the early stage of a project. With valve manufacturers providing realistic manufacturing lead-time information, timely risk mitigation can be exercised to ensure valve delivery does not impact the overall project development schedule.

CONCLUSION

Valve FEL brings value to project owners and EPCs as well as manufacturers. The optimal window to perform valve engineering is during the FEED phase. FEED involvement allows major valve technical challenges to be addressed without huge cost and schedule impacts. FEED stage involvement by a valve FEL team ultimately results in a well-defined valve technical definition before the RFQ stage.

Rocky Goh is director of the project valve engineering (PVE) program for Valves and Measurement, Cameron, A Schlumberger Company. He has more than 40 years of technical and project management experience focused on facility engineering, estimating, construction and project management. Reach him at PVE_Enquiry@cameron.slb.com.

References

- Jeannie Lewis, 2016, What Internal Best Practices Can Do for Valve Selection, VALVE Magazine Spring 2016, Vol. 28, No. 2

- Jens Ebert, PE, 2013, The Right Tools for the Job: Front-End-Loading, www.chem.info/article/2013/12/right-tools-job-front-end-loading

- Gerbert van der Weijde, 2008, Front-End Loading in the Oil & Gas Industry: Towards a Fit Front-End Development Phase

- Three Houses Consulting, 2008, Front-End Loading, www.threehouses.com/frontendloading.htm

- Rashad Zein, 2011, Lessons Learned in Engineering Development for Major Projects, presented at the 55th Annual Meeting of AACE International, Anaheim, California

RELATED CONTENT

-

The Role of Valves in HAZOP Studies

Process hazard analysis (PHA) is required by U.S.

-

Valves in Space

All of these valves need to be built to precise fits and finishes and to stringent performance requirements because “On a spacecraft, everything has got to work. If it breaks, you’re done.”

-

The Diverse Role Valves Play in the Chemical Industry

The chemical industry is extremely diverse with more than 60,000 known products. Like all process industries, the chemical industry needs valves designed for safe, efficient and reliable process operation.

Unloading large gate valve.jpg;maxWidth=214)