Five Key Criteria for Selecting Low-Temperature Valves

Specifying and consulting engineers, engineering houses, original equipment manufacturers (OEMs) and end users depend on valves to control the flow of compressed air or other fluids and on cylinders to control motion.

#automation

Several manufacturers offer specially designed fluid automation products for environments that may experience ambient temperatures as low as -40° F (-40° C). These devices are intended for use with process valves in oil and gas, hydrocarbon, energy, refining, industrial heating, food and beverage, power, vehicular and other applications.

Most standard models are rated for reliable operation down to only 32° F (0° C). During long, cold months in places such as Alaska, the north central U.S., Canada, the North Sea and Siberia, fluid automation products must perform well under harsh, frigid conditions, often unattended and frequently at remote sites that render repair or replacement more difficult than usual. Even in warmer climates, cold storage or low-temperature processing lines present special challenges for material flexibility and seal integrity.

Five Key Qualities

When purchasing valves, cylinders and other fluid automation devices for application in low ambient temperatures, there are five key qualities to consider.

1. Reliability and reputation

Lack of resiliency/flexibility and dormancy can cause degraded performance in valves used in low temperatures.

Resiliency and flexibility suffer as temperatures drop. The elastomers in a valve disc or diaphragm depend on their resilient, elastic consistency to make a good seal with the valve seat. As they get colder, elastomeric polymers shrink and also undergo glass transition, entering a hard, brittle, glass-like state. Both of these changes prevent consistent conformity of the disc against the seat, allowing a leak path to form.

Dormancy occurs when valves are operated at infrequent intervals such as low-cycling applications. When a valve’s O-ring seals stay in uninterrupted contact with the body or main spool of the valve for days or even months, the seal can actually adhere against the grooves or imperfections in the metal surface of its mating components. Once operated, it responds slowly, or not at all.

Both these issues threaten reliable operation of the valve. Simple steps during assembly, such as applying high-grade lubricants that maintain serviceable consistency in the cold, can help combat surface friction. High-quality valve suppliers will also address potential problems by carefully selecting elastomers that stand up to low temperatures, as well as by designing valve seals that are optimized for frigid conditions. Dormancy may be virtually eliminated with innovative construction such as replacing O-ring seals with new T-shaped seals, which present a much smaller surface area at the point of contact.

As with valves, cylinders used in low ambient temperatures can face their own issues. When it comes to resiliency, cylinder seal elastomers can encounter brittleness and shrinkage, in addition to different rates of thermal expansion and contraction for adjoining materials. This creates the possibility of potential leak paths. Cylinder manufacturers counter these risks by designing for minimal gap tolerances, and by selecting special cold-tested O-ring and seal materials that can retain sufficient flexibility at low temperatures.

Cylinders used in frigid conditions may face the same dormancy challenges as valves, with stick and slip problems possible for surfaces that remain in contact for long periods. To fight friction and counteract dormancy, advanced models may be permanently lubricated during assembly with carefully selected low-temperature lubricants. In addition, on critical dynamic parts such as rod and piston seals, manufacturers may incorporate special constructions such as spring-energized lip seals.

Can a given valve provide consistently safe, reliable performance in your application at -40° F (-40° C)?

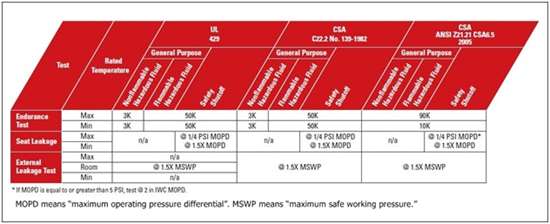

For example, the following table shows similar UL and CSA testing requirements for both general purpose and safety shutoff valves. Both agencies include testing for endurance,valve seat leakage and external leakage.

Beyond testing to these minimum agency standards, suppliers may go on to conduct additional tests that are not agency-required. For example, they may perform tens of thousands of added endurance testing cycles. Further thermal tests may include cycles at high and low ambient temperatures, as well as in saturated conditions in which the temperature of the valve and the air media put through the valve are all kept at -40° F (-40° C) for extended periods to best simulate real-world operating conditions.

3. Breadth and depth of offering

Many users report a strong preference for limiting their choice of supplier to organizations that offer the widest possible selection of products for low temperatures. To consolidate inventories or to meet worldwide specifications, some global companies now specify certain low-ambient-temperature valves from a single source—and use them exclusively for a given application, even in warmer regions.

4. Low temperature and low power

Simultaneous with the requirements for valves and other devices that will function in low temperatures have come similar needs for devices that will also work on low power. Users may simply appreciate lowering energy costs. More critically, in remote locations such as oil and gas transmission pipelines or extraction sites, conventional valves may require heat tracing or protection. These and other power demands often necessitate larger, more costly power supplies such as battery charging systems or solar panels. Therefore, some suppliers have responded with models that meet criteria both for low temperatures and low power.

Besides units that draw the least possible current at all times, some newer models feature peak-and-hold technology, which typically draws 11 watts (W) just at opening, then remains open at only 0.5 W or 1 W. Any valve well-optimized for low power may enable users to specify smaller battery banks, or run the valve longer without sunlight, or merely ensure less drain on backup generators or batteries.

5. Service and support

Choosing the right source for low-ambient-temperature valves often means considering much more than hardware. Finding a partner with the availability and support programs you need can prove equally important. Look for catalog and ordering materials that are clear and easy to use. Some suppliers let users download 2D drawings and 3D models directly into their CAD software, a feature that is highly advantageous for OEM designers.

Explore responsiveness issues, and whenever possible, question distributors about their relationship with specific valve manufacturers.

Perhaps most crucially, consider availability. When you need a particular fluid automation device, you often need it right now. Unfortunately, many users say that availability has become a critical weak point in recent years. Make sure the supplier you ultimately select can provide convenient local stocking and fast delivery — ideally via a quick-shipment program that publishes high on-time delivery rates.

Conclusion

Selecting fluid automation devices for service in low ambient temperatures presents some unique challenges. Users, designers and other specifiers must give close attention to critical issues of reliability, testing and compliance, variety of selection, low-power capabilities and support. The result will be solutions that deliver reliable performance in the colder corners of the world for years to come.

Bob Cadwell is business development manager, ASCO. Contact him at info-valve@asco.com.

RELATED CONTENT

-

New Technologies Solve Severe Cavitation Problems

An advanced anti-cavitation control valve design enabled by 3D metal printing solved a power plant’s severe cavitation problem and dramatically improved its bottom line.

-

Selecting Non-metal Materials for Valve Components and Coatings

Non-metallic materials are commonly used for valve components, and the selection of non-metallic materials for valve design and for application-specific conditions is critical to ensuring product reliability.

-

The Fundamentals of Gate Valves

The venerable gate valve remains a primary choice for many service applications.

Unloading large gate valve.jpg;maxWidth=214)