Green Technology: Waste Not, Want Not

While much of the hope for America’s energy future rests in advances in unconventional oil and gas production, a revolution in green technology is also helping to pave the way to energy independence.

#automation

New Technology – Cellulosic Ethanol

While ethanol production is a well-established process, it is one that uses corn, and detractors of ethanol mandates argue that ethanol production is far from green. They posit that, besides the tremendous amount of water required to grow the corn, it actually takes fossil fuels to run the machinery to plant and harvest the crop, which effectively negates the CO2 reducing benefits of ethanol. Others argue that ethanol production removes valuable corn from the food chain, decreasing the amount available for human consumption and animal feed.

There is, however, a new technology that utilizes the waste generated both during ethanol production and from the raw material left in the fields after harvest of food crops. The technology has been in research for decades, but it is only in June of 2014 that the first commercial facility opened to produce ethanol from something other than corn starch. The Quad County Corn Processors plant in Galva has made Iowa's first commercially produced gallons of cellulosic ethanol from corn kernel fiber. The new facility utilizes the waste generated by the corn ethanol biorefinery that has already been operating onsite since 2000.

The technology was made possible with a $4.25 million investment from USDA and the Department of Energy as part of the Biomass Research and Development Initiative. The R&D process spanned four years. Also under development are other cellulosic ethanol plants that will turn corn leaves and stalks, wood scraps and even garbage into ethanol. DuPont Danisco is building a $225 million cellulosic ethanol plant and Poet-DSM is building a $250 million plant in the northwest Iowa town of Emmetsburg. Both are “bolt-on” plants, meaning they are next door to an existing ethanol plant and both will use corncobs and husks collected from area farmers' fields to make cellulosic ethanol.

Green Construction

There is an ever-increasing focus on green building throughout North America. Efficient HVAC systems and waste heat and water recycling are among the valve-intensive technologies being used to achieve energy savings, and there is even a new trade association dedicated to green building.

One of the most impressive projects is a residential subdivision in Canada. The technology is state of the art, and it is the only facility of its kind in the world. The Drake Landing Solar Community is in Okotoks, Alberta, hardly the geographical location that first comes to mind when we think about solar energy. This Calgary suburb incorporates dozens of green attributes such as a gutter-and-barrel system that saves rainwater, sustainably harvested lumber, recycled drywall and insulation that makes the homes 30% more efficient than standard abodes.

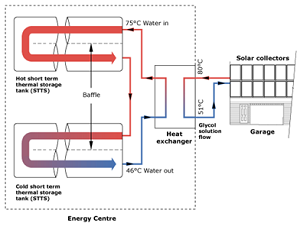

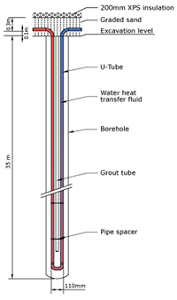

The biggest technological feat, though, is the district heating system made possible by a borehole thermal energy storage (BTES) system. The BTES is an underground structure that stores heat collected via a solar thermal collection system consisting of 800 flat plate solar panels organized into four rows mounted on the detached garages behind the homes. An antifreeze solution (water and non-toxic glycol) is pumped through the solar collectors and heated whenever the sun is out. The 800 collectors are connected via an underground, insulated pipe that carries the heated solution to the community’s energy center.

When solar-heated water is available to be stored, it is pumped into the center of the BTES field and through the U-pipe series. Heat is transferred to the surrounding soil and rock, and the water gradually cools as it reaches the outer edge and returns to the energy center.

When the homes require heat, cooler water is pumped into the edges of the BTES field and as the water flows to the center it picks up heat. The heated water passes to the short-term storage tank in the energy center where all pumps and control valves are located. It is then circulated to the homes through the district heating loop.

Despite the long, cold winters, this system supplies 90% of residential space heating needs of the community.

Geothermal Power from the Salton Sea

The 2014 Annual U.S. & Global Geothermal Power Production Report issued by the Geothermal Energy Association (GEA) found almost 700 geothermal projects currently under development in 76 countries. While growth in the international geothermal market was up, it held steady in the U.S. Of the total global 530 MW of new geothermal capacity in 2013, only 85 MW was in the U.S., according to the new GEA report. Reasons given for stagnation in the market in the U.S. include policy barriers, gridlock at the federal level, low natural gas prices and inadequate transmission infrastructure.

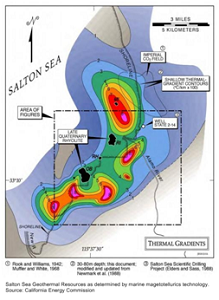

One of the most significant potential sources of growth for the industry is the Salton Sea Resource Area in California where the Imperial Irrigation District (IID) has pledged to build up to 1,700 MW of geothermal power by the early 2030s.

According to the IID, there is more geothermal generating capacity in the Imperial Valley than anywhere else in the U.S. One problem impeding development is the isolation of the Salton Sea; it would take about 150 miles of transmission line to get the power to the rest of California. However, the impending shutdown of several coal plants and the idled San Onofre nuclear plant mean that California’s baseload power will soon be less stable, so the geothermal industry is hopeful the state will come to recognize the technology’s potential and consider it an important piece of its Renewable Portfolio Standard (RPS).

Energy from Bugs

Finally, in a truly unique project, engineers at Stanford have devised a new way to generate electricity from sewage, not from waste heat, but by using naturally occurring "wired microbes" as mini power plants, producing electricity as they digest plant and animal waste. It will be some time before this new power system will be commercially viable to use in places such as sewage treatment plants, but the scientists--who call their invention a microbial battery--have been able to capture electricity created by microbes.

While they will never take the place of a nuclear plant, it is possible for these bugs to some day provide enough electricity to partially power a wastewater plant.

Looking Forward

There is a project in California which desalinates water using the energy of the sun. It would seem the perfect green solution to providing agricultural water in a drought-stricken land. However, desalination always results in waste material. The brine that is left over has huge concentrations of dissolved solids that cannot simply be transported to a landfill or easily re-used; it is considered hazardous waste.

So, for every promising technology, it is important to consider the environmental effects of the entire life cycle of the project. Only then, can it truly be called green.

Kate Kunkel is senior editor of VALVE Magazine. Reach her at kkunkel@vma.org

RELATED CONTENT

-

The Diverse Role Valves Play in the Chemical Industry

The chemical industry is extremely diverse with more than 60,000 known products. Like all process industries, the chemical industry needs valves designed for safe, efficient and reliable process operation.

-

Paint & Coatings

A walk through a typical valve distributor’s warehouse will yield a contrasting view of either silver or black products.

-

The Basics of Eccentric Plug Valves

Wastewater systems present many challenges to pumps and valves because the flow can contain grit, solids and debris, depending where in the process the equipment is located.

Unloading large gate valve.jpg;maxWidth=214)