The Basics of Eccentric Plug Valves

Wastewater systems present many challenges to pumps and valves because the flow can contain grit, solids and debris, depending where in the process the equipment is located.

#ball-butterfly-plug #water-wastewater #basics

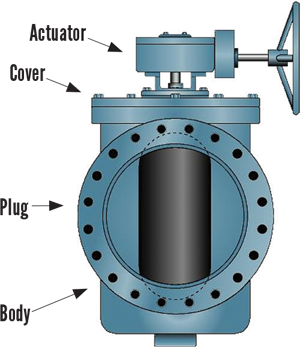

THE VALVE MAKE-UP

First used in the 1930s in the paper industry, the eccentric plug valve can handle fluids with solid content in a manner similar to a gate valve. But the plug valves also provide important advantages of a quarter-turn valve such as modulating service.

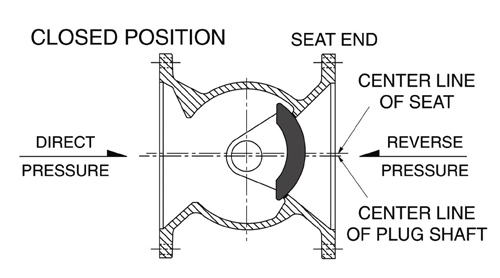

ECCENTRIC ACTION

The unique feature of this valve is that its seat is offset from the valve shaft, thereby providing eccentric action. Figure 3 illustrates the second offset between the centerlines of the seat and shaft. A mid-size valve may have a half-inch second offset. As the valve opens counterclockwise about the shaft, the double offset causes the plug to lift off the seat as it rotates open. The lifting action helps to prevent wear in gritty wastewater service.

Figure 3 also illustrates two pressure directions. “Direct” pressure is applied on the end of the valve opposite the seat and “reverse” pressure is applied on the seat end. The sealing function of the valve is assisted by the direct pressure because it pushes the plug tightly into the seat. The valve will also seal with pressure in the reverse pressure direction, but the plug needs to be turned clockwise past the center of the seat. Because of the eccentric action, the greater the closing rotation, the tighter the seal. If the valve becomes worn during service, it can be closed further to restore a leak-tight seal.

PLUG VALVE STANDARDS

The eccentric plug valve was first standardized in MSS [Manufacturers Standardization Society] Standard SP-108 in 1991. As the American Water Works Association (AWWA) expanded into wastewater applications, it published AWWA Standard C517 (in 2005). Both standards are congruent with similar materials of construction and scope.

Eccentric plug valves are provided in sizes ranging from 3–72 inches with a cold working pressure rating of 150 or 175 psig depending on size and have a flow rating of 8 feet per second. The valves are available in short-body and long-body configurations and are seat-tested in the direct pressure direction unless otherwise specified.

Despite published standards, alternate plug valve designs are available that comply. One design has a cylindrical plug face and cylindrical seat (Figure 2). In another design, the port and plug face are round, similar to a half ball valve. Both designs, rectangular and round, can be provided with standard 80% port openings or full 100% port openings and are piggable using flexible urethane pigs. Plug valves also can be provided with -metal-to-metal seats for severe applications such as activated sludge service.

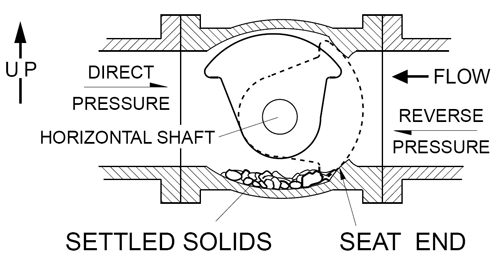

PLUG VALVE INSTALLATION

Because of the geometry of the eccentric plug valve and its use in wastewater service, special installation recommendations should be followed. As shown in Figure 4, when settling solids are expected, the valve should be installed with the shaft horizontal so that when the valve is open, the plug is at the top of the pipe. Also, the seat end should be towards the pump so that when the pump is off, the system pressure pushes the plug into the seat.

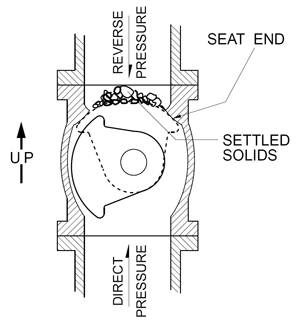

As shown in Figure 5, the valve should be installed for vertical pipes regardless of flow direction with the seat end up so that settled solids will not collect in the valve when closed.

CONCLUSION

The resilient-seated eccentric plug valve is a unique valve in that it is designed to handle wastewater fluids; when equipped with rubber or glass lining, this valve can also handle abrasive fluids. Because it is a quarter-turn valve, it is easily automated for controlling process flow or pressure.

JOHN V. BALLUN, P.E. is the president and CEO of Val-Matic Valve & Mfg. Corp. and a regular contributor to VALVE Magazine. Reach him at jvb@valmatic.com.

RELATED CONTENT

-

CASE STUDY: Water Utilities Can Better Manage Flow Fluctuations with Single Rolling Diaphragm Valves

Without proper pressure management, high-pressure incidents can occur when pumps are turning on or off or when a valve suddenly closes, sending water hammer back through a piping system. Having the right valves to manage large fluctuations in water flow is one way that utilities can balance erratic flows and stay ahead of evolving community demands.

-

Knifegate Valve Maintenance and Repair

Knife gate valves are used to provide isolation in various applications including oil sands slurries, pulp stock, waste water and power generation.

-

Ancient Roman Valves

The story of water supply in the ancient Roman Empire is grand.

Unloading large gate valve.jpg;maxWidth=214)