Misconceptions Regarding Control and Isolation Valve Standards

All on/off isolation valve standards are not created equal and cannot be applied unilaterally to all valves.

#standards

Valve Pressure Classes

One of the most common standards that comes up on every specification sheet is the pressure class. Many valves use pressure classes as defined by ASME B16.34. The most common are CL150, 300, 600, 900, 1500, 2500 and 4500. These do not correspond to a pressure rating in psi. For example, a CL150 valve isn’t only valid for up to 150 psi. These classes are simply designations that define valve design or pressure retaining components.

It is possible to interpolate between different classes as defined by ASME B16.34. One of the most popular interpolated ratings is CL3200 due to the large size difference between a Class 2500 and 4500 valve. Utilizing a CL 3200 valve may help eliminate installed costs associated with piping supports or actuator sizing. Additional, extended, pressure temperature ratings can be applied to welded-end constructions.

Special class valves allow for extended pressure temperature ratings on a standard rating if non-destructive examination (NDE) has occurred. Different NDE methods include radiographic, volumetric and surface, and ultrasonic examination. A limited class valve provides the ability to extend pressure temperature ratings above 900°F as defined by appendix V of ASME B16.34. These capability extensions help minimize costs associated with jumping up to the next standard pressure class.

Fire Testing

The concepts of fire tested and fire safe valves are ones that often seem confused. Fire testing implies that a valve configuration has been tested by a third party to meet one of two primary certifications, API 607 and API 6FA. There are some similarities between tests: specified by API and duration. These are, however, very different standards intended for different valves. API 607 was written to cover soft-seated quarter-turn valves. It would be inappropriate to see API 607 specified for a metal-seated valve. That is not to say that a metal-seated valve cannot pass the test, but that it is outside the scope of the standard’s intentions. API 6FA was written to specifically cover API 6A and 6D valves. A valve referred to as fire safe would imply that it would perform similarly to a configuration that has been certified but hasn’t actually been tested. This is extremely common when metal seals are referenced, because, as mentioned, they don’t fall within the scope of API 607 and are inherently fire safe.

Fugitive Emissions

There are several different emissions standards and protocols. In the control valve industry, ANSI/FCI 91-1 is the most popular standard referenced. ISO 15848 applies to both control and isolation valves and has two testing types, ISO 15848-1 and ISO 15848-2. ISO 15848-1 is a type test that will qualify a valve construction. ISO 15848-2 is a production test for valve constructions that have previously passed an ISO 15848-1 test. Production tests for packing are generally not a standard deliverable from valve manufacturers.

API 622 and 624 are two common isolation valve standards. API 622 qualifies a packing arrangement that could be used in many valve types or styles. API 624 qualifies a valve construction that has certified API 622 packing in it.

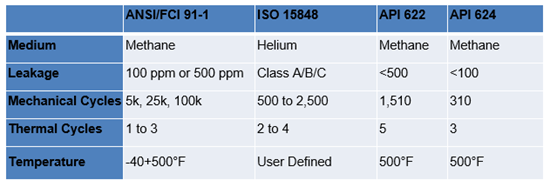

One of the key differences between isolation and control valve packing standards are the testing criteria to which they are certified. The big variance between the standards, as shown in Table 1, is the number of cycles tested for each method. While ISO 15848 can apply to both isolation and control valves and has a relatively low-cycle count, a large discrepancy exists between ANSI/FCI 91-1 and the two API specifications. The minimum cycle count for ANSI/FCI 91-1 is 5,000 cycles, while API 622 only mandates 1,510 cycles. This makes sense as a control valve is tested to much higher cycle rates because it should inherently cycle more often in tracking a set point.

Seat Leak Classes

As with fugitive emissions, there are many different seat leakage classes for control valves and isolation valves. The common ones are ANSI/FCI 70-2/IEC 60534-4, API 598, MSS SP-61 and ISO 5208. ANSI/FCI 70-2 and IEC 60534-4 are in unison with leakage classes and protocol. They range from Class II to Class VI and are defined as a percent of rated valve capacity, except for Class V and VI, which are defined in the standard’s tables max allowable leakage rates in those classes will vary by seal material. Class I is an agreed upon leakage rate between the customer and the vendor.

API 598 is an isolation valve test for seat leakage and body shell testing that requires the valve to pass both a high-pressure test at 110% of maximum cold working pressure and a low pressure test. This standard is extremely common when a floating ball valve is specified. Due to the nature of the floating ball valve, which uses process pressure to obtain shutoff, the low pressure test helps validate sealing in these minimal pressure conditions. MSS SP-61 is another isolation valve standard, very similar to API 598 which specifies bubble tight for soft seat constructions in certain sizes, but allows leakage for metal seats.

ISO 5208 is an international standard that uses rates ranging from A to G. Two of the more common protocols are rate A and D. Rate A is a true, zero-leak test, while rate D seems to be intended more for metal-seated constructions.

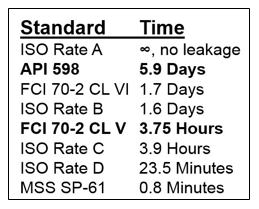

To give an idea of how these rates compare to one another, Figure 1 depicts the time needed to fill a regulation NFL football using the max allowable leakage rates for an NPS 4 metal-seated valve. Official rules of the National Football League require game-use footballs to be inflated to between 12.5 and 13. Psi or 86 to 93 kPa.

Summary

The standards and specifications listed above are not comprehensive or discussed in considerable detail, but the importance of understanding the common principals and purpose of the standards listed on the spec sheets given to your valve suppliers is crucial to the installed performance and lifespan of your final control elements. Specifying an unintended standard to an application may also add unnecessary cost and lead time to replacement or repair of a critical loop.

So, when reviewing your application specification sheets, look for instances where your isolation or on/off valve is calling for ISO 15848 certified packing or your control valve calls for API 598 shutoff testing and take a moment to evaluate your true process requirements.

Andrew Prusha is product marketing manager for Fisher Rotary Valves at Emerson.

Mark Nymeyer is global marketing communications manager for Fisher Flow Controls at Emerson.

RELATED CONTENT

-

The Rationale Behind Valve Characteristics

Back in the “early days,” we were taught that, to properly control flow, we should select a linear valve characteristic when the valve controls more than 25% of the piping system pressure drop at full flow.

-

The Misunderstood Check Valve

Too often this valve is unjustly blamed when problems occur, but the real culprit is its use in the wrong applications.

-

Valve Selection for Bypass of Control Valves: A Case Study

A bypass line including a bypass valve is typically installed to provide continuous operation in case of regular maintenance of a control valve.

Unloading large gate valve.jpg;maxWidth=214)