N.A. Manufacturers: Shifting Sourcing Requirements

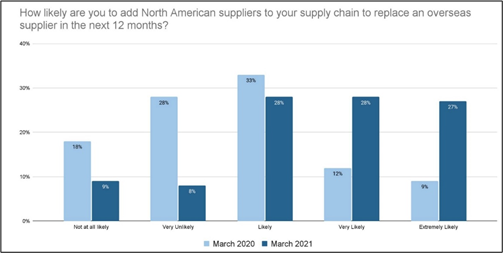

A major trend in North American manufacturing this year is widespread interest in bringing sourcing and production back from offshore, according to the State of North American Manufacturing 2021 Annual Report from Thomasnet.

#VMAnews

Survey respondents reported an average new-supplier contract size of about $900,000. The report suggested that if 83% of the 579,811 manufacturing companies in the U.S. brought on just one domestic supplier with just one purchasing contract of that size, the result would be as much as $443 billion in U.S. economic value.

AN ANNUAL ASSESSMENT

The Thomasnet Industrial Survey, completed in March and April of this year, provided data for the yearly report. The survey queried 542 qualified respondents involved in making decisions in purchasing/buying or production/manufacturing. About one-quarter of them work in manufacturing businesses. The remainder represent a wide range of industries, including energy/utilities, aerospace, defense, construction, food and beverage, oil and gas, automotive, agriculture and medical/healthcare. Company revenues ranged from less than $4.9 million to over $500 million. The report drew on the results of an online survey and Thomasnet.com anonymized user data.

REACTIONS TO COVID-19 CHAOS AND UNCERTAINTY

Data and comments from the respondents showed responses to COVID-19-induced supply chain disruptions. Just-in-time sourcing inventory management seems to be giving way to optimizing availability. Cost savings may no longer dominate in sourcing decisions. Companies need to develop more sustainable solutions that can future-proof their supply chains.

Five percent of U.S. and Canadian respondents said they saw no barriers to sourcing in their home countries. The largest portion of respondents (40%) found price to be the greatest challenge. Others cited speed (23%), quality (19%) and availability (9%) as the greatest obstacles.

The report suggests vertical integration may increase in some industries—companies acquiring upstream and downstream suppliers to consolidate and control their supply chains. Chemical and electronics manufacturing may desire reshoring, it says, but for these capital-intensive industries, such a change is likely to be lengthy and difficult.

To bring production and sourcing back from offshore and compete with low-cost production countries such as China, the report states the U.S. will need to make significant investments in manufacturing technologies and developing the skilled labor needed. Data from The Association for Manufacturing Technology quoted in the report suggests that the investment in technology alone will need to be $400-$600 billion.

VALVE INDUSTRY EXPERIENCES JUMP IN SOURCING INQUIRIES

The report described a sharp rise in the demand for some sectors in North America. Sourcing data shows increased demand for steel, chemicals, paper and other raw materials. At the same time, traditional manufacturing activities showed a similar increase in categories such as casting and stamping services.

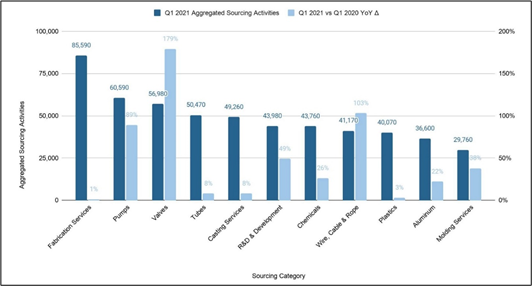

In the manufacturing realm, the valve category turned up as having the most activity among 11 product and service categories, with almost 57,000 aggregated sourcing activities in Q1 2021 (such as page views on Thomasnet.com and requests for information), showing an increase of 179% from Q1 2020 to Q1 2021. See Figure 2.

It remains to be seen where the need for more reliable supply chains and the desire for reshoring will lead. "We are witnessing the wholesale reexamination of supply chain relationships, which will realign global manufacturing for decades to come," said Tony Uphoff, Thomasnet president & CEO. “With North American businesses accelerating reshoring and replacing some of their overseas suppliers with domestic alternatives, U.S. manufacturers are being presented with an unprecedented opportunity."

Barbara Donohue is a freelance technical writer, journalist and former Web editor at VALVE Magazine.

RELATED CONTENT

-

PFAS Chemicals and PTFE: Should the Valve Industry Be Concerned?

Legislation moving through Congress could affect the future use of thousands of PFAS chemicals (per- and polyfluoroalkyl). The house passed H.R. 2467 in July of 2021 and, though the bill is general in nature, it assigns the responsibility to the Environmental Protection Agency (EPA) for determining which PFAS chemicals will be controlled or banned altogether.

-

Additive Manufacturing of Pressure Equipment

How manufacturers can design and produce PED-compliant equipment using additive manufacturing.

-

The Biggest Valves: Sizes Growing in Step with Greater Demand

Valve manufacturers that have the expertise, skills, equipment and facilities to produce large valves are rare.

Unloading large gate valve.jpg;maxWidth=214)