Smart Analytics and the Power Sector

While mountains of data are being created everywhere in the commercial, industrial and manufacturing sectors, problems arise when determining how to handle all of that information and make it a valuable part of the business.

#basics #iiot #automation

Trends in Data Analytics

Tampke pointed to trends that suggest the ways valve, actuator and control companies can help utilities meet this directive:

- Have a stronger focus on business value. “You must show the value of smart systems, and you need to show where the money will come from,” he suggested.

- Transition from point solutions to enterprise focus. You are not providing a system that operates independently; it is one piece of a large puzzle.

- Shift toward forward-looking, predictive analytics. “It’s nice to know about the past,” he said, “but they need to know what's going on into the future. You must help them understand how to use this data to avoid a forced shutdown of a power plant and to prioritize time and resources.”

- Suppliers must be aware of and become more deeply immersed in the tools that operators already have within processes, plans and plants in order to wisely suggest new or additional tools.

Tampke compared traditional analytics, which incorporated stand-alone tools and were independent plans with exclusive conclusions, to the new, smart, cloud-based systems now in use.

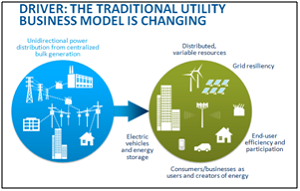

These smart tools make it possible to plan and forecast performance with condition-based alerting and anomaly detection. Smart analytics platforms are unifying tools with real data integration that allow data to be moved to and from central repositories. This means that data can be interwoven across multiple planning sectors – from fuel supply to compliance, to operations, distribution and finances, to integration of power sent back into the system from homes and businesses that create it. Such platforms provide an enriched view of all systems that allows for better decision-making.

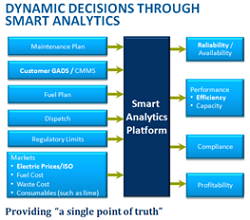

Smart analytics puts all the decisions through an analysis program. This is a platform that includes maintenance plans, customer GADS/CMMS, fuel plan, dispatch, regulatory limits and the markets that include the price of electricity, fuel cost, waste cost and consumables. They can all be fed into the smart analytics platform which then generates data on profitability, compliance, performance efficiency and capacity and reliability/availability. This provides what Tampke called a “single point of truth.”

Challenges to Adaptation

In many facilities, there is often a failure to fully realize the value of smart devices. The technology may be there, but the infrastructure within the plant is not there to support the use of the devices. There may also be a disconnect between the new smart devices and traditional equipment that is already in place, and a lack of willingness to learn how to use it.

What Smart Analytics Means to the Valve Industry

Tampke says it’s important that suppliers and manufacturers be ready and available in the marketplace at the right time.

He asked, “How do your valves/controls fit into the overall system of the power plant? How do they improve the efficiencies?” If you can answer that, you can help the utilities and be in a better position to help them become more profitable. “Better inventory management is part of that. Do they really need all these spare parts? Inventory is something people are getting concerned with and smart analytics can help with that.”

Tampke also notes that these days renewables often are driving the decisions associated with fossil fuel power plant operations, especially natural gas. “It doesn't matter if you believe in global warming or not,” he said, “the decision has been made. How do we respond? The easy wind has been done, but that is causing problems with how the grid operates. We don't necessarily have the wind where and when the need is greatest. So we need fast-acting combustion; there is one natural gas combined cycle that can be up and operating in 20 minutes.

But, he continued, “the effect of cycling on older plants is great. Most of these plants were designed to be base-load units so this is having a tremendous effect on valves and other equipment. We must be aware of the pressures exerted on the entire system. Smart analytics can help that, in this very dynamic world.”

Conclusion

“The way things have been is not the way things are going to be,” warned Tampke. “As you look at manufacturing, be aware that the data you have is important. And it is just as important for the utility sector, so learning to implement smart analytics will make a big difference on success going forward.”

Kate Kunkel is senior editor of VALVE Magazine. Reach her at kkunkel@vma.org.

RELATED CONTENT

-

The Dos and Don’ts of Isolating Pressure Relief Valves

Typically, isolation valves are used to block off a pressure safety valve (PSV) from system pressure, so that maintenance on the valve or related equipment can be conducted without a shut down.

-

The Misunderstood Check Valve

Too often this valve is unjustly blamed when problems occur, but the real culprit is its use in the wrong applications.

-

Fugitive Emissions Standards for Valves

API, ISO and TA Luft all have their own set of standards to control emissions. What are the differences and how do they compare?

Unloading large gate valve.jpg;maxWidth=214)