Being old-fashioned, I still thumb through physical journals and tear out pages. In preparation for writing this article, I spent time reviewing interesting pieces I recently got from industry magazines. One factor I noticed was that every article on the subject of the Internet of Things (IoT) was about applications inside the factory. For example, there were articles on machine monitoring, equipment monitoring, preventive maintenance, and smaller topics.

IoT is relevant for all these areas, but its relevancy begins before the factory floor comes into play and continues beyond that factory. Flipping through the articles I found, I had to wonder: why is no one writing about IoT in the supply chain? Production cannot occur and customers cannot sell what isn’t in hand. IoT is a useful tool for pinpointing where materials are in the supply chain to ensure their timely delivery.

These materials cover the full gamut of the manufacturing process—starting with sourcing raw materials or purchased items, then moving them to the factory, and finally getting the finished product to the job site and stock to distributors. At each of these steps, everyone wants to know where their materials or products are and when they are going to arrive.

- Global positioning system (GPS) trackers show where a truck or a package is.

- Data loggers show what a load experienced in the past.

- Real-time IoT monitoring reveals where a container and its contents are right now.

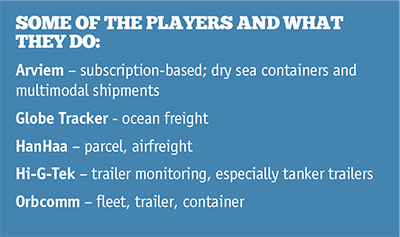

There also are multiple players in the IoT field for supply chains with more entering the market all the time. Each offers different technology, with different purposes and different ways of bringing their solutions to the market (for example: is it coming by purchase or by subscription?). This article cannot cover the full range, but we can look at a few highlights.

Devices

Today, it seems like there is a device for almost every need along the chain. Those devices might fit inside small packages, communicate between packages, roll-up data to a container/trailer or monitor the container and its environment. Some can monitor the tractor of a tractor-trailer combo and connect with an electronic logging device. There even are devices that can be mounted to valves on a tanker trailer to monitor opening/closing or to determine if cargo is being dispensed or stolen. The candy bar-sized device shown in Figure 1 is used for parcel or air cargo tracking.

COMMUNICATION TECHNOLOGY

The most prevalent and cost-effective means of transmitting IoT data back to a monitoring system is via the cellular network. Global System for Mobiles (GSM) is the most popular network, but others are used as well. Although more expensive, some solution providers also offer satellite telecommunications. This is important if data beyond GPS information needs to be transmitted while the cargo is out of range of cell-phone networks. The main application would be cargo at sea. To offer affordable solutions for ocean freight, many providers use GSM when their devices are within range of the cell-phone network and then switch over to satellite technology when out of cellular range. The service provider switches from GSM (which allows real-time data transmission of GPS and the environment) over to the ship’s satellite Automatic Identification System (AIS) which provides info on the GPS of the ship itself. AIS is a vessel identification and tracking system used for collision avoidance, identification and location information. When the device is out of range of the cellular network, it acts only as a data logger. Once back in range, the recorded history is transmitted.

For land-based devices, LoRaWAN is used in some applications. This is a long-range, low-power wide-area network system governed by the LoRa Alliance, an association created in 2015 to support the LoRaWAN protocol and ensure interoperability of LoRaWAN products and technologies. This is likely to be used most often for stationary devices or those operating in a fixed area such as a mine site, wellhead or pumping station. The data transmissions are typically encrypted for security.

BEYOND GPS

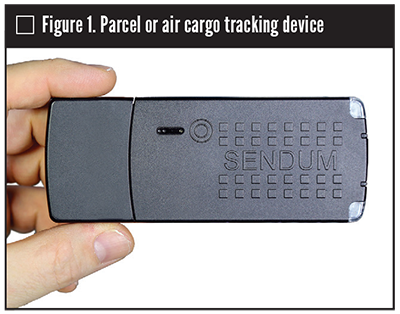

Most service providers offer a simple interface similar to Google Maps. By calling up a tracker ID, users can visualize a map with current GPS information. Drilling down allows visualization of any of the recorded information across the full history of the trip to date (Figure 3).

This is valuable information, but many readers may want to know how these solutions can help in the real world. The following are several real-life results from a cargo track-and-trace solution provider.

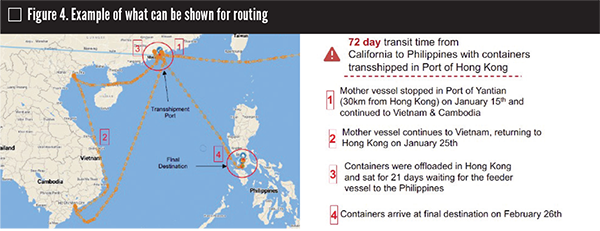

EXAMPLE 1–(MIS)ROUTING

Imagine a scenario where valves are shipped from the U.S. to a construction site in the Philippines. Once the container with the product is on the ship, companies typically have no information about the outbound voyage. However, if late delivery penalties could be applied, you certainly would want to know what’s going on. Also, if you paid a premium for a specific delivery routing, you want to ensure you get what you paid for. Figure 4 is an example of a solution that offers that kind of information.

EXAMPLE 2–INSURANCE CLAIM SUPPORT

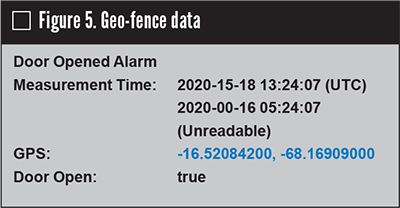

Beyond environmental monitoring, there are geo-fences for high-value shipments. Shippers can be notified if a load goes “out of bounds” or if doors are opened when they shouldn’t be (Figure 5)

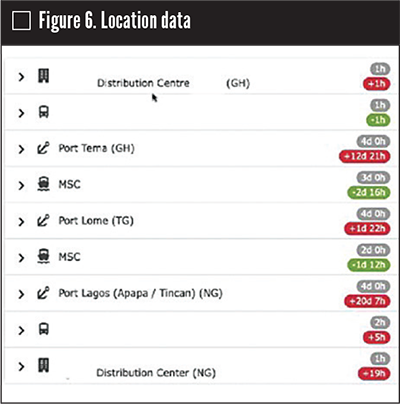

Logistics teams have great difficulty trying to find out where a shipment is or was. Inside some planning offices of the past, tracking was rudimentary, often consisting of binders or bulletin boards full of faxes from carriers or forwarders. The worst problem was not knowing where an overdue load was on its route. Anyone who has experienced unplanned port disruptions knows what I mean. I vividly recall waiting weeks to find out the status of a container stuck in the port of Rotterdam during a particularly heavy shipping season. Wouldn’t it be nice to check the status online? Not only could you “see” where the load is now, you could tell how long it has been there (Figure 6).

WRAP-UP

Beyond tracking of individual shipments, cargo tracking and tracing solutions can build up a wealth of data that can then be analyzed for future decision-making. For example, carrier performance can be tracked, route selections modified for better delivery, damage analyzed by route or carrier and much more. This is where IoT of the supply chain can be a real value-added tool that supports the logistics team. Best of all, this information can be only a click away.

STEPHEN CHERLET is owner/founder of FarStar S.A.C. Consulting (www.farstarconsulting.com) and chair of the national board of directors at Supply Chain Canada (www.supplychaincanada.com). Reach him at stephen@farstarconsulting.com.

RELATED CONTENT

-

An Overview of Butterfly Valves

A key advantage of selecting a butterfly valve is the reduction of space and weight to a system compared with other options such as ball, check, globe or gate valves.

-

Ball Valve Basics

Welcome to the first in a series of Valve Basics articles, each focused on a major product type and written especially for newcomers to the industries that use and make valves and related products.

-

Stop Check Valves

Stop check valves are vital to several industries to protect boilers and other equipment.

Unloading large gate valve.jpg;maxWidth=214)