In any industry, one of the most challenging tasks is keeping up to date and compliant with complicated and changing sets of performance standards. In an ideal world, these standards serve a vital purpose by guiding employees and end users to the most efficient application of their equipment.

Unfortunately, good intentions can turn into overzealousness, creating a situation in which performance standards create as many problems as they solve. To make matters worse, many industries face competing sets of standards from multiple agencies and advocacy groups, making it even more difficult to understand and employ suggestions and guidelines. An ideal set of performance standards would be unambiguous and easy to interpret, leading industry stakeholders to proper decision making. But that’s not usually the case.

In waterworks service, pressure rating standards are used to define the acceptable use of flanged valves. However, because of the many variables involved in using flanges, these standards can be complicated and difficult to interpret. Compounding the issue is the fact that workers in the water service industry must contend with standards issued by several organizations including the American Society of Mechanical Engineers (ASME) and the American Water Works Association (AWWA). The complex and often contradictory standards issued by these two organizations, in addition to manufacturer literature that can muddy the waters further, can lead to misunderstandings or improper application.

HIGH STAKES

For a pipe system to perform reliably and successfully, each of its component parts must function properly. Any weakness or improper application of equipment can result in higher construction and maintenance costs as well as decreased efficiency. Those responsible for specifying, constructing, maintaining and assuring performance of pressurized systems must have a complete grasp on the pressure ratings of every component in their system to ensure they perform their intended function safely.

DECIPHERING THE STANDARDS

In considering pressure rating standards for valve flanges, a broad range of factors must be understood. Each of these factors (e.g. material, size, temperature) impacts the resultant pressure rating (measured in pounds per square inch gauge or psig).

Valve flanges are constructed of different materials, including steel, stainless steel, gray iron and ductile iron. These materials have different mechanical properties, and because of this, they are assigned different pressure ratings. Ductile iron, for example, has a higher rating than gray iron, while the rating for steel is considerably higher than either iron alloy.

Flange sizes are measured by the size of the pipe and expressed as nominal pipe size (NPS). This measurement does not correspond precisely to the size of the pipe in inches; rather, the measurement is a dimensionless reference to the nominal diameter (DN) in inches used in international standards. DN standards are also dimensionless. The relationship of NPS to DN can roughly be calculated as DN = NPS x 25. As NPS increases, the pressure rating of the flange decreases.

In addition to flange sizes as measured in NPS, flange thickness also must be taken into account. Flange gaskets are found in one of three variations: smooth gasket, flange-type gaskets and triple-seal gaskets. (For a comprehensive report on these factors, consult AWWA C111, Rubber-Gasket Joints for Ductile-Iron Pressure Pipe and Fittings.)

Temperature is the final factor in determining the pressure rating of valve flanges. Because metals are weaker at higher temperatures, for a given material, pressure ratings decrease as temperature increases. The noticeable disparity in ratings between high-temperature situations and low-temperature situations is what prompted AWWA to issue its own set of standards specific to cold water service.

ASME Standards

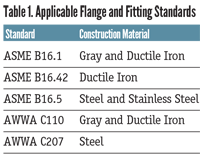

ASME recognized the importance of reliable standards and were first to create a set of performance standards for valves, flanges and fittings in 1920. Three relevant sets of ASME standards for flanged valves and fittings exist and each of them corresponds to construction material. Gray iron flanges and fittings correspond to ASME B16.1. Ductile iron flanges and fittings correspond to ASME B16.42. Steel flanges and fittings correspond to ASME B16.5. (See Table 1, page 19.)

AWWA Standards

AWWA then issued its own set of standards specifically for cold water service. AWWA C110 applies to ductile iron and gray iron flanges and fittings. AWWA C207 was developed more recently and applies to steel flanges and fittings. Because these standards are designed for cold water service, their pressure ratings are higher than ASME ratings for fittings of similar size and material. This is due to the fact ASME fittings are expected to deal with more hazardous service situations.

Classes

The most outwardly confusing aspect of pressure rating standards is inclusion of classes. These classes are designations based on a specific pressure and temperature for saturated steam. Pressure classes are not based on pressure ratings from the flange—a reality often misconceived. (The determination of pressure classes was described in a November 2014 VALVE Magazine article, “Understanding and Selecting Valve Flanges, Pt. 1: Design and Standards.”)

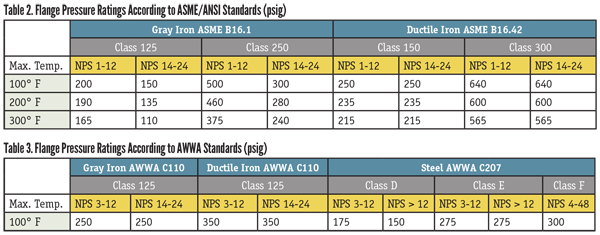

In all sets of standards, as the class rating increases, the pressure rating increases. As observed in the ASME standards found in Table 2, class rating never corresponds exactly to pressure rating at temperatures of 100°F, 200°F or 300°F (38°C, 93°C, 149°C).

An important note is that Class 125 and Class 150 flanges use the same bolting pattern and can be bolted together despite the fact they have different pressure ratings. The same principle holds true for Class 250 and Class 300 flanges. Gray iron flanges are flat-faced, while ductile iron flanges are typically flat-faced and steel flanges can have either raised or flat faces. Because of this potential incongruity, gray iron flanges can only be bolted to ductile iron or steel flanges if the raised face of the mating flange is removed or if the mating flange is also flat-faced. This precaution prevents the breaking of a gray iron flange when tightening the bolts.

Tables 2 and 3 (page 20) provide reference for the various pressure rating standards assigned by ASME and AWWA. ASME B16.5 prescribes several tables for different materials and temperatures, the details of which are beyond the scope of this article. To ensure compliance, the tables found in the published standard should be consulted. It is important to note that the AWWA standards are only listed with a maximum temperature of 100°F (38°C) because of their exclusive design for cold water service.

Valve Pressure Ratings

Complicating the issue further is the fact that, even when there is a clear understanding of the ASME/ANSI and AWWA pressure-rating standards for flanges, the reality is that the flange is not the only part of the piping system that must be acknowledged. Just as crucial is the valve itself, and unfortunately, valve pressure ratings can differ entirely from the pressure ratings of a flange in the same class.

The issue of valve pressure ratings is complicated even more than flange ratings because there are significantly more variables involved. The prescribed standards of the ASME and AWWA for flanges are based on standardized dimensions. However, waterworks valves differ considerably in size, shape and design depending on the manufacturer, making it impossible to come to such a relatively concise set of standards.

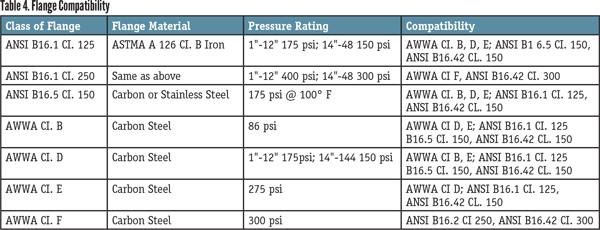

AWWA has issued standards for many of the valves used in water service, but users must be cautious when using these standards in combination with AWWA pressure-rating standards for flanges. The pressure ratings often differ within a given class, and a responsible service provider must understand these differences to prevent accidents. The key factor to understand is that a piping system is only as strong as its weakest component; all decisions related to pressure should be built around the pressure rating of the system’s weakest link. (Table 4)

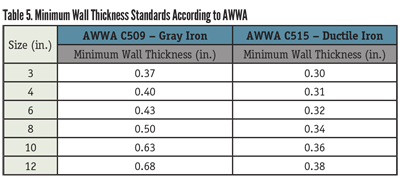

MINIMUM WALL THICKNESS

STANDARDS AS THEY APPLY

While we can clearly identify and define the ASME and AWWA standards germane to the use of flanged valves in waterworks service, the simplest way to determine which standards are applicable to specific equipment is to consult the manufacturers’ recommended standards for individual products. This can be cross-referenced with Tables 1, 2, and 5 to determine the figures relevant to that equipment to ensure the best match.

TIM FALLON is product line leader for Mueller Water Products (www.muellerwaterproducts.com). Reach him at tfallon@muellerwp.com.

RELATED CONTENT

-

Pressure Relief Valve Basics – Spring-Loaded Safety Relief Valves

Learn for the first time or brush up on this common valve product.

-

What’s Your Temperature?

For decades, valve manufacturers have provided the maximum recommended working pressures and temperatures for their products, based on the materials used in the pressure-containing parts.

-

Introduction to Pressure Relief Devices - Part 1

When the pressure inside equipment such as boilers or pressure vessels increases beyond a specified value, the excess pressure may result in a catastrophic failure.

Unloading large gate valve.jpg;maxWidth=214)