Valve Automation Solution for Unconventional Shale Gas Challenge

With the rapid development of unconventional shale plays throughout the U.S. has come the challenge of transporting product to refiners and markets.

#automation

What is “Unconventional Gas Play”?

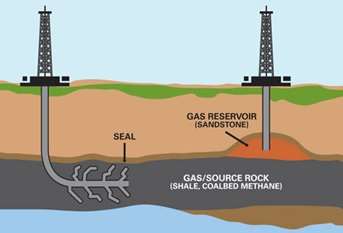

An unconventional gas play involves extracting the natural gas from within shale formations. The gas is embedded in rock rather than a bubble or pocket of gas captured over water or oil.

There are about seven major active shale plays across the U.S., and throughout all plays, many sites contain multiple well heads to make it possible to gather the gas in the most-efficient way possible.

This results in large volumes of gas that then must be gathered in pipelines, many of which traverse populated areas and roadways.

Transporting Challenge

Because of the quantities of gas, gathering lines may be of larger size and higher pressure than traditional pipelines, and many are routed through high consequence areas (HCAs). An HCA is an area where pipeline releases could have greater consequences to health and safety or the environment. To deal with the growth in this sector and to insure safety of the public in the vicinity, the U.S. Department of Transportation Pipeline and Hazardous Materials Safety Administration (PHMSA) has indicated it may further study regulation of large size and higher pressure gathering lines. Regulation typically involves a requirement for shutoff valves in high consequence areas to add protection in the event of a natural gas release.

A large midstream pipeline company recently installed a pipeline that will eventually be flowing produced natural gas that contains hydrogen sulfide (H2S). The pipeline is routed under a major South Texas Interstate highway in the Eagle Ford. This highway is busy with a lot of interstate commerce transportation.

The company needed rapid closing valves on each side of the highway for emergency shutdown in the event of a gas leak or line break. In the event of an emergency, the pipeline company also did not want to send personnel to the valves because of the time it could take to react and to eliminate their exposure to the possible lethal gas.

Control and Actuation Requirements

It was important that the actuator would be able to close the valves locally on site using hydraulic power or a manual hand pump, remotely from gas control, and/or automatically by responding to pressure sensors on the pipeline. The control system had to monitor the pipeline pressure, react if linebreak conditions were detected, and signal the actuator to close the line valves.

In addition to these requirements, it was essential the overall system be reliable with minimal maintenance.

Challenges

Normally, a gas/hydraulic actuator would be used and powered with the pipeline gas. However, that was not possible in this instance because of the H2S content. To complicate matters further, this is a desolate site, so there was no utility electric power available. Electric motor actuators were not selected because a sizable reserve power source would be required to assure speed of operation and reliability.

Solution: Power Source

A battery-powered electrohydraulic system was chosen to provide hydraulic power. A charged accumulator provides the power to achieve the speed requirement and for additional stroke capability. Batteries are kept adequately charged by a bank of solar panels aimed at the South Texas sun.

Solution: Actuator

A rotary vane type actuator was selected because the hydraulic actuator can operate the valve smoothly and the hydraulic fluid will protect the internal components from the harsh South Texas environment.

A hand pump was included for manual operation backup if the power fails.

Solution: Control

Linebreak detection was provided by the Emerson LG 2300 linebreak detection system, which constantly monitors line pressure. This allows the customer to determine normal pressure variations and compensate settings before arming for automatic closure.

The system will then alarm or close the line valve when the rate of drop, low- and/or high-pressure set points are exceeded. It also alarms if the accumulator head pressure is too low for adequate reserve power.

For added reliability, the linebreak detection system has a power system separate from the electrohydraulic power unit. The pipeline company also added communication that allows valve position visibility at the gas control site in another state.

Summary

The pipeline company has the capability to monitor these two valve settings, and remotely close them in the event of an emergency. They are also collecting data on the actual pipeline flow conditions, and it is their intention to configure the detection system setting to automatically close the valve if the set points are exceeded.

Leon Berckenhoff is senior regional sales manager for Emerson Process Management (www.emersonprocess.com). Reach him at Leon.Berckenhoff@Emerson.com

RELATED CONTENT

-

Valves in Oxygen Service

In his presentation at VMA’s 2017 Technical Seminar, Kurt Larson, a process control engineer for Air Products, spoke about the inherent danger of the oxygen production business and how it is particularly important for end users and valve manufacturers to work closely together.

-

An Overview of Butterfly Valves

A key advantage of selecting a butterfly valve is the reduction of space and weight to a system compared with other options such as ball, check, globe or gate valves.

-

Control Valves for Hydrogen Applications

Proper sizing, material selection and monitoring are as important as ever.

Unloading large gate valve.jpg;maxWidth=214)