What's the Chatter About Check Valves?

Sizing and selecting the right check valve type can avoid any problems before they start.

#basics #gate-globe-check

Have you ever heard a check valve chatter? Having been on numerous job sites and spoken with maintenance personnel at many different corporations over the years, it seems to be a common occurrence. When asked if they have heard check valves chattering (typically a clink-clink-clink type sound happening rapidly) they have all heard that sound at one time or another.

If you are hearing this sound from your check valves continually, your check valve (and/or spring if it’s spring-loaded) is oversized for your application. Essentially, there is not enough flow to fully open the particular check valve part number currently installed in the system.

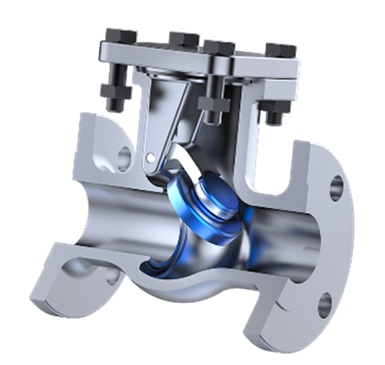

In the case of a swing or double-door (butterfly) type check valve, often your only option is to reduce valve size (as compared to line size) to try to create more flow velocity to fully open the check valve.

For a piston/poppet or ball-type check valve, they are typically spring-loaded. There can be two options with this type of check valve (depending on the manufacturer/valve series):

- Reduce valve size to increase pressure drop to try to get the check valve fully open (just like a swing or double door check).

- Reduce the spring cracking pressure so that less pressure drop is needed to fully open the check valve.

Your next question may be, “Well, how can I ensure that the check valve I’m selecting for my in-line checking application will be fully open (no potential for valve chatter)?” Great question, and the good news is there are answers!

For a swing or double-door type check valve, there is a minimum flow velocity requirement for whichever manufacturer, series and size of check valve you are looking at. It is always best to reach out to the manufacturer to see what the minimum velocity requirement is for the check valve that you are looking at. If you are not reaching that required minimum flow velocity, then your check valve is partially open. Any partially open check valve has the potential to chatter. Any check valve that chatters will likely wear prematurely (sometimes severely). Additionally, the actual pressure drop through the check valve will be higher as a partially open valve has a lower Cv value than it does when fully open.

For a piston/poppet or ball-type check valve, there would be a minimum pressure drop requirement to fully open a given check valve. This can vary by manufacturer, series and size. For most manufacturers, the minimum calculated pressure drop requirement is around 2 to 5 times the spring cracking pressure. Anything less than the required minimum pressure drop would mean the equation is inaccurate (since you are inputting a fully open check valve Cv), the check valve is partially open, and there is potential for check valve chatter. As previously stated, any partially open check valve can chatter. Any check valve that chatters will likely wear prematurely (sometimes severely).

In general, you want to size the check valve (and the spring if it has one) for the application, not necessarily the line size. Check valves only operate off the flow, pressure, specific gravity and temperature of the media in the system. There is no external actuation on a check valve like there is on a control valve. More specifically, there is no manual, electronic, pneumatic or hydraulic actuation on a check valve like there is on a control valve.

With a control valve, you can ensure that it is fully open regardless of what’s going on with the flow in the system since it’s actuated. With a check valve, it’s totally dependent on the flow conditions as to whether or not enough velocity or pressure drop is created to fully open it. On a normal in-line checking application, you want your check valves to be fully open to eliminate the potential for valve chatter and to help maximize check valve life.

There are other types of applications like noncode pressure relief, vacuum relief, injection, back pressure regulation and holding static liquid head pressure where you need to look at sizing a check valve differently for those types of services. Check with your manufacturer for the proper guidelines on those specific application types.

To summarize the key points, keep the following in mind for an in-line checking application:

- Any partially open check valve can chatter.

- If a check valve chatters, it will likely wear prematurely (sometimes severely).

- Size the check valve (and spring if it has one) for the application, not necessarily the line size.

- Swing and double-door (butterfly) check valves will require a minimum flow velocity to be able to fully open.

- Piston/poppet and ball check valves will require a minimum calculated pressure drop to be able to be fully open.

- Check valves that are not meeting the minimum flow velocity or minimum required pressure drop will also not have an accurate calculated pressure drop, as the valve is not fully open, so the full Cv value is not available.

- Always reach out to your manufacturer for questions on check valves, including sizing.

Noah Miller is the worldwide applications/engineered sales manager for Check-All Valve and has been with the company since 2010. He has been active with VMA since 2017 and is currently on the Education & Training Committee.

RELATED CONTENT

-

Back to Basics: The Nuts and Bolts of Torque and Tension

Torque is a force that causes an object to rotate, while tension is a force that causes an object to stretch or elongate.

-

The Future of Valve Manufacturing is Already Here

Companies in the valve and control products industry are responding to a confluence of forces that are changing the landscape of manufacturing — automation, agility and digitalization to name a few.

-

Back to Basics: Globe Valves

There are many applications where the globe valve outshines other designs, so the future is still bright for these long-time favorites of the flow control industry.

Unloading large gate valve.jpg;maxWidth=214)