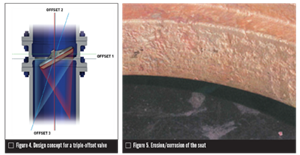

Evolution of Butterfly Valves on Aircraft Carriers

Butterfly valves are an integral part of keeping an aircraft carrier’s firemain system operating smoothly.

#ball-butterfly-plug #automation #knowyourvalves

Distributors: Can Technology Make Your Business More Agile?

Modern industrial distributors, especially those working with valves and related equipment, generally have a great reputation for being good at providing services and technical information.

#automation

Augmented Reality: Is the ROI Worth the Effort?

If you could improve safety and efficiency in your plants, lower travel costs and more efficiently train employees with one technology, would you consider adopting it?

#iiot #automation

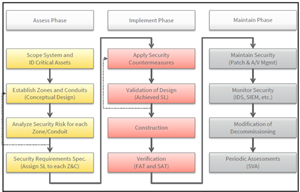

Integration of Automation Lifecycles: Functional Safety, Cybersecurity and Alarm Management

Risk management of a manufacturing process requires a deep dive into the functional safety, cybersecurity and alarm management lifecycles.

#iiot #automation

Fracturing Technology in the New Age

After the oil crash of 2014, producers needed to refine the technology even further to bring costs down while meeting new industry challenges.

#automation

Metal Additive Manufacturing in the Valve Industry

Metal Additive Manufacturing (AM) is a fascinating technology that has gained acceptance over the past several years.

#materials #automation

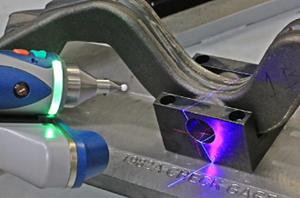

Advancements in Blue Laser Scanning

As the industrial world continues to expand in its use of CAD data and 3D digitizing technology, the advances in blue laser scanning and structured blue light are further supporting industrial operations throughout the design, manufacture and aftermarket servicing processes.

#automation

The VMA Knowledge Forum, Part One: Technology at the Forefront

The first VMA Valve Industry Knowledge Forum, April 11-13 in Savannah, GA, provided a potpourri of topics for valve industry professionals from all disciplines.

#VMAnews #automation

Will Smart Machines Obsolete Human Resources?

Is artificial intelligence (AI) going to take over manufacturing jobs and the jobs of human resources professionals?

#iiot #automation

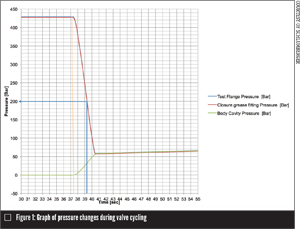

Unique Operating Dynamics of Trunnion-Mounted Ball Valves

For a very long time, the idea has existed that a trunnion-mounted ball valve can be opened under full differential pressure if the piping system can withstand the rapid increase in pressure and the forces induced by it.

#ball-butterfly-plug #pressure-relief #automation

Inspiration and Automation: Keys to Best-in-Class Operations

For the last several years, at industry gatherings of all kinds, the subject of automation is guaranteed to dominate the conversation.

#automation

Remote Monitoring of Cooling Towers and Air-Cooled Heat Exchangers

Advances in wireless technology have made remote monitoring of process equipment and systems much easier and less expensive than previously thought possible.

#automation

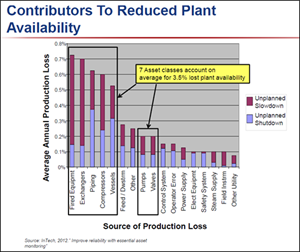

Achieving Profitability Through Maintenance Management

One of the distinctions between maintenance requirements in a capital-intensive process facility and those of other industries is the high cost of production equipment and the corresponding cost of maintaining that equipment over its lifecycle.

#automation #maintenance-repair

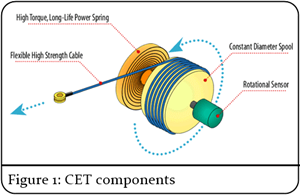

Control Valve Positioner Performance Diagnostics

There has been discussion for some years about the accuracy of measuring control valve travel with the use of the original equipment manufacturer (OEM) measuring element versus the use of independent valve analyzers.

#automation

Wireless Technology Optimizes Production in Mining Operation

Natural Soda operates seven production well pairs in Colorado to produce saturated nahcolite brine for manufacturing sodium bicarbonate (baking soda).

Mining nahcolite requires very careful monitoring of temperature, pressure and flow to not only optimize production performance—but also to mine the product sustainably and protect the freshwater aquifer.

#pressure-relief #automation

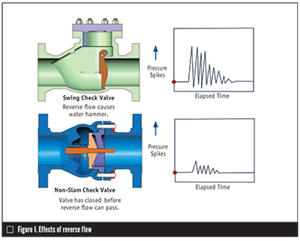

Water Hammer

Water hammer is a shock wave transmitted through fluid contained in a piping system.

#automation #water-wastewater #basics

Turning the Tables on Valve Corrosion

Multiple valve manufacturers and users worldwide are finding the value of valve preservation centered on vapor corrosion inhibitor (VCI) technology and related strategies.

#automation

Video Game Technology Changing the Offshore Industry

One of the most powerful innovations in training staff for offshore oil rigs was developed thanks to the video game industry.

#basics #automation

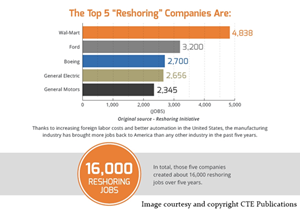

Reshoring, Robots and What Happens if We Do Bring Jobs Back?

While offshoring is painted as the major villain in the decline of numbers of manufacturing jobs in the U.S., automation may actually be a bigger threat.

#automation

The Challenges of Slurry Valve Packing

Because of the difficulties of dealing with slurry as a medium, the equipment assigned to move it along faces many challenges.

#automation