Flowserve Receives First FDT 2.0 DTM Certification from FDT Group

The newest certified Logix 3820 Series DTM is deployable with positioners supporting HART 6/7.

#automation

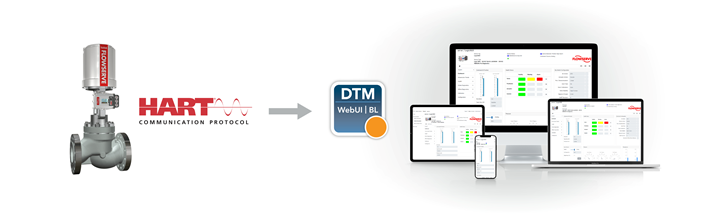

FDT Group, an international, non-profit industry association supporting the evolution of FDT technology for industrial device management, today announced certification of its first Device Specific DTM based on the latest FDT 3.0 standard supporting the HART protocol from Flowserve Corporation. The newest certified Logix 3820 Series DTM is deployable using their positioners supporting HART 6/7, tackling flow control challenges designed for modern IIoT architectures.

FDT DTM certification to the FDT 3.0 specification and webUI is a process whereby rigorous compliance testing using dtmINSPECTOR5 ensures the viability of the states of the DTM; its correct installation, de-installation, and multi-user environment capability; mandatory and optional user interface functionality and robustness; network scanning communication performance and the ability to import and export the topology; and the audit trail capability.

“Flowserve is proud to be the first vendor to offer a software-based webUI DTM based on FDT 3.0,” said Manjunath Atchutanna, global digital technology manager at Flowserve Corporation. “The industry is transformative with flow control applications designated as critical control. Our new DTM meets modern use case challenges that extend standardized device management for valve control to mobile solutions and other higher-level applications using OPC UA, enabling service-oriented maintenance scenarios.”

FDT 3.0 DTMs are crucial to unlocking universal device integration with essential advantages such as platform independence, mobility solutions, and a contemporary development environment to reduce costs and expedite the DTM certification process. Users can use secure and seamless data exchange/interrogation from the sensor to the cloud and achieve new levels of information technology (IT) and operational technology (OT) integration.

“This certification is a milestone in market penetration and technology development,” says Steve Biegacki, FDT Group managing director. “Flowserve has always been a leader in flow control using DTM technology and now offers the first flow control management DTM standardized for IIoT architectures based on FDT 3.0 for HART applications. HART users can deploy this new DTM and reap the benefits by using an FDT 3.0-based device management tool, such as PACTware 6.1, and can enjoy an IT/OT data-centric model by deploying an FDT Server, extending the data reach to mobile applications and the enterprise.”

RELATED CONTENT

-

Stop Check Valves

Stop check valves are vital to several industries to protect boilers and other equipment.

-

Check Valves: The Most Important Valves in Your Process System

Check valves, as critical as they are for flow system performance, often don’t receive the respect they are due, said Arie Bregman, vice president and general manager, DFT, Inc., in a recent VMA presentation.

-

Valve Basics: Electric Actuator Controls

Electric valve actuators control the opening and closing of valves. With a motor drive that provides torque to operate the valve, these actuators are frequently used on multi-turn valves such as gate or globe and also on ball, plug and other quarter-turn valves.

Unloading large gate valve.jpg;maxWidth=214)