While the Canadian winter sees a sizeable portion of the population scurrying to points south, those bone-chilling temperatures left behind will eventually provide relief in Toronto during the humid, hot summer months. This is because of a phenomenon that occurs with Lake Ontario.

During the chilly months, the surface of Lake Ontario cools to about 39°F (4°C), which means the water is denser and sinks to the lake’s bottom. In summertime, the surface water heats up, but that water remains on the surface because it is not dense enough to sink. However, no matter how hot the ambient temperature during the summer, the deeper water remains very cold. This creates a permanent reservoir of cold water on the bottom of Lake Ontario that can be used for cooling.

To use the renewable energy of this cold water, Enwave Energy Corporation created Deep Lake Water Cooling (DLWC), the world’s largest lake-source cooling system. For this article, Alex Sotirov, Enwave Energy Corporation’s vice president of engineering, provided details that describe the system he helped design and install and how that system works.

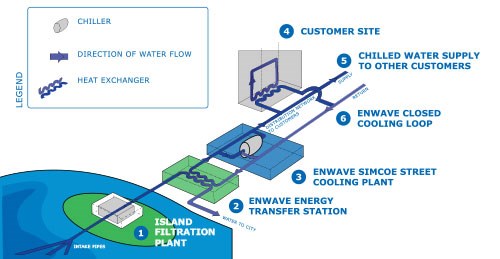

Three 63-inch high-density polyethylene (HDPE) pipes are installed along the natural slope of the lake bottom to pump water from a depth of 273 feet (83 meters) to the Toronto Island Filtration Plant, which is 3.1 miles (5 km) away (Figure 1). Because this water ultimately ends up in the city’s potable water system, the pipes and valves with which it comes into contact are specified food grade. Enwave uses American Water Works Association standard valves.

At the intake, 52-inch carbon steel butterfly valves direct the cold water to Enwave’s energy transfer station at the city’s John Street pumping station. These valves were chosen because they take up less space, are lighter than gate valves, and have packing and seating designed to last 80 years.

The closed loop contains supply and return pipes running in a tunnel built specifically for this purpose.

About 7.5 miles (12 km) of underground pipe has been installed beneath the city’s core to serve as a distribution network. The loop runs from Simcoe Street near Lake Ontario north through the financial and hospital districts to Queen’s Park and back to where the pipe system begins. The downtown closed loop is made of steel and HDPE and contains over six million gallons of water. The flow rate through the system peaks at over 72,000 gallons per minute (gpm) and averages over 30,000 gpm.

A back-up system for the city’s closed loop has been constructed for situations such as high heat days: 14,000 tons of additional back-up cooling can be provided by two steam-powered centrifugal chillers and two traditional electric centrifugal chillers. In routine circumstances, the heat from the loop is removed using lake water alone and what flows through the downtown loop will bypass the four supplemental chillers.

For use here, there are full bore, 48-inch ball valves handling pressures of 120 psi. By using specialized access points, maintenance crews can test the valves, and adjust and replace seating and packing without removing the valves.

The chilled water passes from the main Enwave system into each building’s cooling system via a two-position, motorized butterfly valve that sends it to a metering system and then through a series of control, isolation and balancing valves to the building’s system.

After conveying its energy to the building’s internal system, the Enwave chilled water continues its journey through the system. Meanwhile, each building’s internal closed loop system uses thousands of valves, including manual isolation and ball valves, to convey chilled water to individual offices. As new customers want to go online or as new skyscrapers are built, the system can accommodate needs simply by drilling from the basement of a new building into the Enwave dedicated tunnel.

But what happens to the lake water itself, many wonder. The answer is that it has never mingled with the Enwave system; only its energy has been conveyed to the closed system.

BENEFITS OF DLWC

The benefits of the system are numerous. Building owners appreciate it because Lake Ontario serves as the engine of cooling, eliminating the need for electrically powered chillers. This frees up significant square footage and reduces maintenance costs for retrofits at existing buildings. It also saves hundreds of thousands of dollars in capital investments at new construction.

The DLWC also reduces the need for hydrochloroflourocarbon- and chlorofluorocarbon-based refrigerants. And, even though the water running through the system warms up about 2°F (less than 1°C), when it enters the city’s potable water system, minimal heat returns into the lake, and no extra water has been used to accommodate the system.

Like any project, this system is ultimately dependent on the components of which it is comprised. For that reason, high-quality valves designed to last decades are key to ensuring its continued reliable service.

Kate Kunkel is senior editor of VALVE Magazine. Reach her at kkunkel@vma.org.

RELATED CONTENT

-

Testing of Hydrogen Valves

Valves are used to control all types of fluids, and while some are easy to manage, others can be a challenge. At the top of the challenging list sits hydrogen, the smallest, lightest molecule known to man.

-

Proper Care of Knife Gate and Slurry Valves

How to resolve—and avoid—field failures of knife gate and slurry valves

-

Dealing with Sand Erosion in Control and Choke Valves

Sand erosion in control and choke valves is a significant consideration offshore.

Unloading large gate valve.jpg;maxWidth=214)