Air Valves in Piping Systems

Liquid piping systems are prone to collecting air from incoming fluids, pumps and connections.

#basics

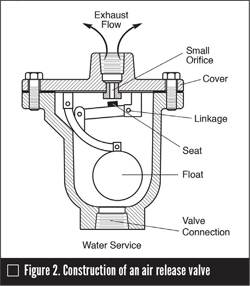

Air release valves, which expel trapped air in a pipeline, are familiar to most people, but many other types of air valves are out there that have special functions, unique construction for wastewater and sizes up to NPS 20. Safeguarding piping systems from air-related problems requires knowing how to select and install the right air valves.

TYPES OF AIR VALVES

Three basic types of air valves are defined in American Water Works Association (AWWA) Standard C512 for use in water and wastewater, including:

- Air-Release

- Air/Vacuum

- Combination

AWWA air valves are constructed of iron or stainless-steel bodies with corrosion-resistant trim for water and wastewater service. An important point here is that these air valves have a different function than pressure and vacuum relief valves, which are installed on the top of gas or steam pressure vessels and liquid storage tanks to provide overpressure protection. Relief valves have set points designed to provide overpressure protection and are beyond the scope of this discussion. The air valves presented in this article automatically control the flow of air or gases in and out of liquid piping systems at all operating conditions.

Air Release Valves

Air/Vacuum Valves

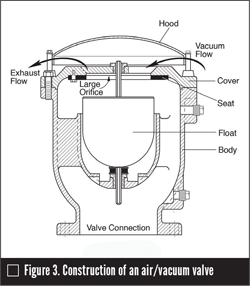

A common application for air/vacuum valves is for the discharge of vertical turbine pumps. This is because after shutdown, the piping between the pump and the check valve fill with air. When the vertical turbine pump is started, it rapidly lifts the column of water, and the trapped air must be expelled before the water opens the check valve. An air/vacuum valve is the right fit for this application because it can rapidly expel large volumes of air and close when fluid fills the air valve.

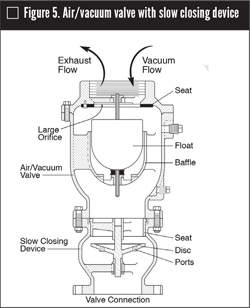

Another optional device for an air/vacuum valve is a slow-closing device. This device is commonly used for pipeline applications where column separation may occur. One purpose of this device is to close when high exhaust rates might occur. It’s also to regulate the exhaust rate of the air valve so that the water column does not slam into the air valve and cause water hammer or damage to the air valve. The slow-closing device can be mounted on the inlet of clean water valves and on the outlet of wastewater air valves when column separation or vacuum conditions might occur.

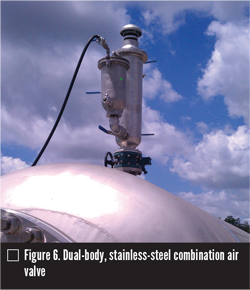

The third type of air valve is the combination air valve, which contains the functions of both the air/vacuum and air release valves. A combination air valve can be furnished either as a single-body design, where a singlebody contains both air release and air/vacuum components, or as a dual-body design (Figure 6), where an air release valve is piped to the side of an air/vacuum valve. The two configurations perform the same functions. However, the single-body design can be more economical while the dual-body design can provide design flexibility when sizing the orifices.

LOCATIONS ALONG A PIPELINE

Air valves are generally installed on liquid piping systems to exhaust air or gases and admit air to prevent vacuum conditions and air-related surges. The AWWA Air Valve Manual recommends air valves at various locations including high points, long runs, adjacent to mainline valves, downstream of pumps and where there are changes in pipe slope. Valve manufacturers provide online computer software to assist in locating and sizing air valves.

Installation methods for air valves are important to ensure their proper function (AWWA, 2016). The best results are achieved when the air valve is mounted directly on top of the pipe. Unfortunately, some pipelines are located under roadways, which requires the air valve be mounted in a separate vault. In these cases, it is important that the connecting pipe be sized for the flow conditions and slope upward to the air valve. Furthermore, extended air valve piping can have a multiplying effect on surges, so a transient analysis may be needed to evaluate this piping.

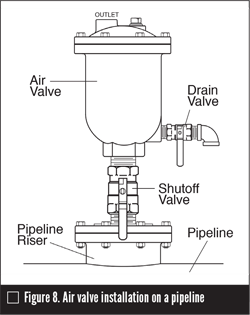

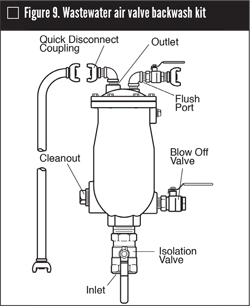

For maintenance purposes, all installations should include a shutoff valve under the air valve. Also, to help in collecting the air that travels along a pipeline, a riser pipe larger than the air valve inlet is recommended (Figure 8). A drain valve can be used to annually check the function of the air valve. If the drain valve expels air, the air release portion of the air valve may require maintenance or repair. Otherwise, the air valve should be observed during a pump operation to verify it is exhausting air and closing without excessive leakage.

Caution is needed when inspecting or performing maintenance on an air valve. This is because when the system is functioning, an air valve can release large quantities of air under pressure or admit large quantities of air under vacuum conditions. Both can cause bodily harm. Any maintenance on an air valve requires closing the shutoff valve under the air valve. But even with the shutoff valve closed, pressurized air can be trapped in the air valve. This is why care is needed when venting the air through a drain valve or pipe plug before removing the air valve cover.

CONCLUSION

When air is allowed to accumulate in pressurized pipelines, efficiency is sacrificed, and serious system damage can occur. By having an understanding of the various types of air valves, system designers can better select and install air valves to protect liquid piping systems.

JOHN V. BALLUN, P.E. is the president and CEO of Val-Matic Valve & Mfg. Corp. (www.valmatic.com). Ballun has been a contributor to valve standards development work for American Society of Safety Engineers, AWWA, and Manufacturers Standardization Society (MSS) and is a past president of MSS. Reach him at jvb@valmatic.com.

References

1. American Water Works Association, VALVE Magazine, “Why Air Valves are Needed in Water Applications,” Spring, 2017, pp. 32-34

2. American Water Works Association, AWWA C512-2015, Air Release, Air/Vacuum, and Combination Air Valves for Water and Wastewater Service

3. American Water Works Association, AWWA M51, 2nd ed., Air Valves: Air Release, Air/Vacuum, and Combination, 2016

RELATED CONTENT

-

Ball Valve Basics

Welcome to the first in a series of Valve Basics articles, each focused on a major product type and written especially for newcomers to the industries that use and make valves and related products.

-

Understanding Torque for Quarter-Turn Valves

Valve manufacturers publish torques for their products so that actuation and mounting hardware can be properly selected.

-

Valve Basics: Electric Actuator Controls

Electric valve actuators control the opening and closing of valves. With a motor drive that provides torque to operate the valve, these actuators are frequently used on multi-turn valves such as gate or globe and also on ball, plug and other quarter-turn valves.

Unloading large gate valve.jpg;maxWidth=214)