“Borrowing” a Distributor Partner’s Capabilities

Plant owners, operators and purchasing managers have a challenging job: They must make sure their plants run with little downtime, maximum safety and top efficiency.

When a plant has a procurement team, they’re often focused on purchasing direct material, while maintenance, repair and operations products (MRO) and indirect purchases take a backseat. This means any time a plant needs to purchase a new piece of equipment or MRO supplies, department leaders and engineers are taken away from the manufacturing business and into the business of procurement.

One solution is to lean on distributor partners and their capabilities.

GETTING THE PRODUCTS

When we look at total cost of ownership, we look past the price to all the costs associated with purchasing, storing and paying for the product. Those costs add up fast (Figure 1).

In fact, according to Exel Analysis and Supply Chain Insights, for every dollar of unit price spent on a product, two dollars of support cost can be associated with the product price. That means if the focus is solely on the purchase price variance, it’s likely more will be paid in total cost of ownership including excessive repair or replace costs. How can that be?

An abbreviated list of support costs (not including repair or replace costs) looks like this:

- Sourcing

- Ordering

- Shipping

- Taxes

- Tracking

- Handling

- Warehousing

- Warranty tracking

- Payment processing

- Invoice reconciliation

- System support

- Inventory optimization

- Returns

Imagine accruing those support costs over the course of a year, averaging 1,000 purchases each month from more than 500 suppliers? Then compound those costs year after year. This shows total cost of ownership is often substantial, and in the long run, can be five to 10 times the cost of the product.

When a plant manager is busy running the plant, these functions can sometimes be rushed through or fall to the wayside altogether. Oftentimes, there isn’t a dedicated plant employee devoted to keeping procurement costs down. This is where a trusted distributor partner can step in.

In today’s industry, distributors seek to be more than just suppliers. They are also solution providers, identifying solutions for their customers that are geared at lowering a plant’s total cost of ownership.

THE RIGHT ERP

Enterprise resource planning (ERP) technology is the platform a business uses to manage processes and track resources. It does everything from purchasing to payment to inventory management to payroll and beyond. When it comes to total cost savings, the ERP platform can be a plant’s greatest asset or its weakest link.

Unfortunately, ERPs aren’t cheap. They can cost upwards of $2 million for a system, plus the cost of upgrades to keep it current. Once a business is invested in its ERP, they’re in it for the long haul. Meanwhile, there are more than 10 major ERPs commonly used by industrial plants and distributors. To complicate matters, those ERPs rarely have the ability to seamlessly “talk” to each other to make interfacing and transacting possible.

DISTRIBUTORS AS SERVICE PROVIDERS

Today, a distributor that also has in-house supply chain services can essentially “lend” its system functionally to customers, lowering an industrial plant’s total cost of ownership. The system can “talk” to the plant’s system, working together to streamline most business processes. When a distributor partner has the right supply chain capabilities, then the customer can operate reliably on the distributor’s system. This means the plant can have a totally separate ERP, an outdated ERP or no ERP at all and still benefit from the functions of this particular supply chain service provider’s operating system.

Imagine placing all of a plant’s purchases through a common operating system that links to just one of the distributor’s supply chain services operating systems. This particular distributor, who also might have supply chain management capabilities, acts as a procurement partner, essentially allowing the customer to place all purchases, no matter the product category, through a common system. All orders can be placed in one system but are transferred to the individual suppliers’ systems. Instead of 500 separate invoices a month, there would be one or two. Plus, managing invoices, making payments, reordering inventory, returning products and other tasks all run through this one operating system.

- Volume by category or supplier

- Supplier delivery performance

- Item availability

- Fill rate accuracy

- Receipts and issues

- Purchase order replenishment

- Savings commitments

- Performance to budget

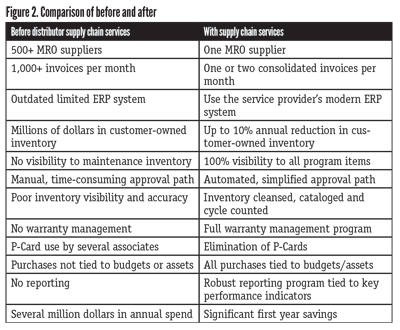

An example of how using the distributor in this way can improve total cost of ownership is shown in Figure 2.

Summary

Industrial plants must always consider more than just the unit price of the products they purchase to keep operations running. When distributors take the next step to turn into service providers—helping to reduce plant operational and labor costs using technology—they’re ultimately able to save their customers time and money in the procurement and inventory management process.

TIMOTHY GREGG is a general manager for Wolseley Industrial Group’s (www.wolseleyind.com) Integrated Services team. Reach him at timothy.gregg@wolseleyind.com.

RELATED CONTENT

-

Intermediate Class Valves, the Forgotten Classification

These days, piping designers use automated systems that default to standard classifications such as pressure classes of 150 to 2500 for valves and associated equipment.

-

What’s Your Temperature?

For decades, valve manufacturers have provided the maximum recommended working pressures and temperatures for their products, based on the materials used in the pressure-containing parts.

-

Creating a Standard for Severe Service Valves

Severe service valves are offered in several standard designs, including non-return, isolation and control types.

Unloading large gate valve.jpg;maxWidth=214)