Ball Valves in Power Plants

Can metal-seated ball valves provide effective long term, economical solutions for critical applications in steam-generating power plants?

#ball-butterfly-plug #automation #materials

During the last 20 years, advances in machining, tooling, measuring and coating technology have led to ball valve designs that provide positive sealing solutions for the power industry. These new “power plant ball valves” can withstand temperatures and pressures that make them a viable solution for the industry.

THE HISTORY

Before these new designs, creating true and matching spherical sealing surfaces was limited so that one surface—the ball—typically was metal and highly polished. The second sealing surface—the seat—generally was a fluoropolymer or elastomeric compound. This combination works well in lower temperatures and pressures, and still is widely used today. However, it is not suited for the extremes seen in steam power generating stations.

The sealing areas of the plug and seat are matched conical surfaces, which are well-suited for the high pressures, temperatures and velocities found in vent, drain and continuous process services. Operation of the valves is intuitive: If the stem is in the “up” position, the valve is open; if the stem is in the “down” position, the valve is closed.

METAL-SEATED BALL VALVES

Computer numerically controlled (CNC) machines with special tooling can now produce virtually perfect spherical metal-to-metal sealing surfaces—both concave, and convex for ball and seat—with almost infinite repeatability. Highly qualified and specialized coating contractors also can provide many varieties of flame-sprayed carbide coating compounds applied with exacting precision in laboratory conditions by CNC robotic machines. These coatings carry a toughness and hardness far exceeding that of the cobalt-based weld overlays traditionally used in rising stem globe valves, and the final coated surface exactly mirrors the machined contours of the underlying part. These technologies have lead to the emergence of the power plant ball valve, capable of withstanding temperatures in excess of 1050° F (566° C) and pressures in excess of 3000 psig.

CONSTRUCTION FEATURES

Many power plant ball valve manufacturers are machining valve bodies from forged bar stock materials with massive wall thicknesses far exceeding that of rising stem valves. Several use the same valve body design on 1.5-inch and smaller sizes for all pressures classes—so that an ASME Class 1500 valve may actually have an ASME Class 4500 body. This standardization reduces raw material inventory, streamlines machining, shortens production times and allows for virtually unlimited alloy material selection. Usage is restricted by the pressure and temperature rating stated on the original equipment manufacturer (OEM) tag and relevant American Society of Mechanical Engineers (ASME) and American National Standards Institute (ANSI) standards.

OPERATION

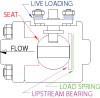

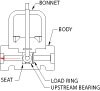

They have only one seat located downstream of the ball. This downstream seat, the upstream bearing ring, the conical load spring, and the ball are a matched set, fitted very precisely into the body cavity so that, when assembled, the final stack height does not allow the ball to float.

Under extreme pressures, the ball must remain centered on the shaft and centered within the downstream seat and the upstream bearing ring. The conical load ring compensates for thermal growth of the internal parts at elevated temperatures and provides the initial sealing force in applications involving slowly building pressures—such as firing a boiler.

Bi-directional service is an available option offered by several manufacturers of power plant ball valves, but this option must be clearly specified up front. Operating torques for ball valves are determined by the differential pressure of the system acting on the exposed surface area of the closed ball. The size of the hole through the ball (the port size) is one factor that determines the closed surface area of the ball since the closed surface area must be larger than the port. Larger closed surface areas mean higher operating torques. This is significant because operating pressures in power plants can exceed 3000 psig. Consequently, power plant ball valves are routinely produced with reduced port sizes to keep the operating torques low. For example, a power plant ball valve with a nominal pipe size of 1.5 inches may have an actual through-port opening size of only 5/8 inch.

SELECTION

The port size should be considered when specifying power plant ball valves. A reduction in port size causes an increase in system pressure loss through the valve, which results in an increase in fluid velocity through the restricted port. Power plant ball valves were originally and primarily designed for vent and drain applications. Since vents and drains normally are used for short durations, the increase in velocity through the ball port does not produce a large wear factor. However, in continuous process applications, the system pressure loss and the velocity also will be continuous, which can mean premature failure of restricted port valves.

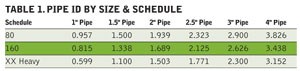

High energy piping systems in power plants use schedule 80, 160, and XX-Heavy pipe. Table 1 shows the correlation between pipe size and pipe internal bore for several nominal pipe diameters and schedules.

Power plant ball valve manufacturers use the relationship between nominal pipe size and pipe internal diameter to determine “standard” port sizes. Several companies publish dual Cv values—one for the valve and one for the valve installed in heavy wall piping. The port size, the system operating characteristics and the piping configuration during the valve selection process should receive close attention. For example, if the ball valve is to be used for isolation either before or after a control valve, the question becomes: How will a smaller or larger port affect the control valve performance?

Many power plant ball valve manufacturers offer increased port sizes as an option. Largely, this option is a result of the “TDP-1-1998 Recommended Practices for the Prevention of Water Damage to Steam Turbines Used for Electric Power Generation,” which offers guidelines for the relationship of the valve port size to the nominal pipe diameter. The intent is to ensure that any water or condensate in the high-energy steam pipes leading to the turbine is drained as efficiently and as quickly as possible, with no carry-over.

Selecting the largest available port size may seem to be the safest route, but increasing the port size also increases the purchase price. If the valve is to be automated, the larger port size will warrant a larger, more costly actuator as well. Also, the location of the valve in the piping system may restrict the amount of available space for larger actuators.

The piping system dynamics should be carefully evaluated to determine the potential for bi-directional flow or for the potential to have greater pressure downstream than upstream. This can occur, for example, under flashing conditions when drain valves discharge into a common header. Bi-directional sealing must be specified during the selection process, and selecting this option will increase the cost, and often the torque, of the valve.

AUTOMATION

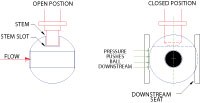

Ball valves are vastly easier to automate than multi-turn and rising stem valves partly because operation of the ball valve is a simple 90-degree turn. Because of the internal flow path through ball valves (Figure 7), the vast majority of power plant ball valve automation occurs with two position actuators—open and close. Throttling, or operation in partially open positions, is not recommended for these valves.

Power plant ball valves are concentric in operation: When the lever handle is removed, there are no stops, and the ball can be rotated 360 degrees. Since there is only one sealing seat, unidirectional valves are normally furnished with the seat side of the ball lapped and the other side unlapped, a relationship that must be maintained. The installed actuator will have stops that must be properly set to accurately control both the opening and closing positions of the ball. These positions are equally important. If the valve is not fully opened, premature wear may occur on the leading edges of the ball and on the sealing surface of the seat. If the valve is not fully closed or if the unlapped side of the ball is on the seat side of the body, then the valve will leak, and the leaking fluid will damage the sealing surfaces.

Most manufacturers prefer to automate their own valves or will have designated automation distributors and representatives. Since power plant ball valves are normally weld-end valves, the actuators are often removed during the welding process. If the actuator is removed and reinstalled by non-authorized personnel, factory warranties may be voided. These issues should be addressed during the selection process, or a ball valve with integral stops should be specified.

INSTALLATION

Proper clearances must be allowed for lever handles and actuators because misalignment can cause either short stroking and cause the stem side to load, which leads to premature failure.

Those who purchase or install ball valves for the first time or who are purchasing from a new manufacturer need to request and become familiar with welding procedures. Questions that need to be addressed include: Should the valve be welded into the piping with the ball opened or with the ball closed? Normally the opened position is preferred to prevent weld splatter from coming in contact with the sealing surface of the ball. Since power plant ball valves are metal-seated, the location of the welding ground connection should be considered because arcing can occur across the ball and seat if improperly grounded.

Heat-treating requirements should be carefully evaluated and understood. Manufacturers prefer that heating be applied to one end of the valve at a time and localized to the welding area only. Wrapping the entire valve with heating blankets, particularly around the seat and the stem packing area, is not recommended. However, time constraints during emergencies and shutdowns often force the heating of both ends simultaneously—in this case, the situation should be discussed with the manufacturer or authorized representative.

As this article seeks to show, when properly selected and installed, power plant ball valves are providing effective solutions for leak-free isolation services in steam generating plants.

STEVE SPILKER is power division manager for Mid-States Supply Company (www.midcoonline. com/web), headquartered in Kansas City, MO. Reach the author at Steve.spilker@midstate.com.

RELATED CONTENT

-

In the Air: Wireless Trends in Smart Pneumatics

In today’s wireless world it’s no surprise that automation and manufacturing spaces have embraced—and sought out—the connectivity and convenience that wireless technologies offer.

-

Leak Testing Gas Components and Systems

Leak testing is performed for four basic reasons, says John McLaren, product manager, leak detection at Agilent Technologies, Inc.

-

Recycling Foreign Metals: Buyer Beware

The North American steel-making industry, with its historic record of quality control, is no longer the world’s top producer.

Unloading large gate valve.jpg;maxWidth=214)