Inexpensive Safe Water Tapped by Correcting Control Valve Output

The error output from a control valve can come from a variety of sources: uncontrolled input pressure, uncontrolled input flow rate, inaccurate orifice size or turbulent flow through the system which causes irregularity of flow rates through the system.

#water-wastewater #pressure-relief #controls

For processes where transitory flow rates must be precise, such as chemical mixing, errors in valve output can have a significant or even unacceptable effect on quality. Just as an airplane going through turbulence experiences variation in flight path compared to laminar flight, a valve with turbulent flow has varying output compared to laminar flow as is seen in this video.

Solution from an Unexpected Source

An unexpected development occurred while attempting to create a valve system to control the flow of hydrogen gas more safely. At the time, media reports on the danger and difficulty in storing hydrogen gas in automobiles was the impetus for working on a solution.

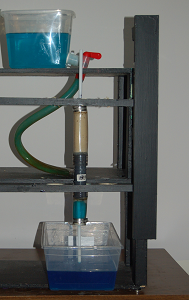

When building the prototype, gravity feed of water was the most reliable source of fluid flow available. The initial idea with the early prototypes was just to build something that did not leak and would provide reasonable variable control.

But I noticed that the system had unexpectedly smooth flow rates. And with the use of a gravity feed system I was using for this prototype, applications other than compressed cylinders of gas came to mind.

The Valve

The design for the shaft valve is a simple combination of a long shaft-like poppet with grooved surfaces to provide and accurately sized orifice. The long shaft allows for easy operator setting of the orifice size. A seal with tangential contact with the poppet at the orifice which limits flow seems to create laminar, rather than turbulent flow, to create a steady state flow rate. Gravity is the most reliable source of energy, and pressure, on the planet. When a gravity feed or other source of pressure regulation is combined with a precise orifice, which is easy to set and clean with a laminar flow pattern, the result is a valve with no discernible error or fluctuation. Flow rates that are both predictable and steady.

Results of Ongoing Testing

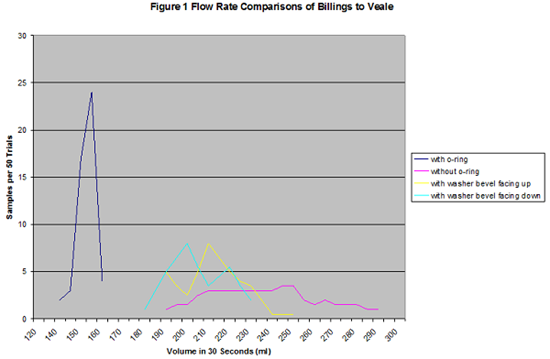

As Figure 1 shows, the standard deviation over the average flow rate is 2.9% for the new valve tracked in dark blue. It is 11.4% for the closest known design on the far right. The middle two curves are for modifications on the new valve with metal seals that are only beveled on one edge. The 2.9% error for the new valve is within the confines of experimental error. This new valve has no discernible variance in flow and can be precisely set. The wide range in output from older designs can pose problems for many applications.

Applications

A valve which has more reliable flow rates, with reduced or essentially zero variance in output, can serve many applications without these electronic controls. Even in systems with existing control loops, inclusion of a valve with reduced error within the control loop will reduce the burden on the electronic control system. Industrial processes such as the mixing of epoxy are one possible application, or the control of temperature using fluid flows in critical temperature heat exchangers.

Small Scale Drinking Water Treatment

Worldwide, millions of people fall seriously ill and many die every year from contaminated water. While progress has been made on this issue, the combination of growing populations and dwindling water resources threatens this progress with regression and threatens to start conflict. Increasing shortages of ground water and surface water are also projected in North America, complicated by the fact that some industrial processes and agricultural practices pose an increasing threat to them.

While there is certainly a need in developing nations, there is also a need in North America for small scale water treatment. More than 200 million North Americans live within ten kilometres of an impaired water source. These waters can have everything from pharmaceutical metabolites to industrial effluents to anti-flocculants like alum used in municipal water treatment plants. Any surface or ground water from North America should now be suspected of having some contamination unless proven otherwise. Meanwhile, water tables are also dropping throughout the continent.

Rainwater

Using an inexpensive, easily assembled system with a shaft valve, it is possible for a single suburban home to collect 26,000 gallons (100,000 litres) of water per year. If the collection and treatment of this valuable resource was made inexpensive and easy to maintain, not just on homes but also in industrial and farming buildings, a simple system could do much to alleviate the increasing challenges of providing safe water to large swaths of the population.

As seems to be the case with many discoveries, the search for a solution for one problem resulted in solutions for another. It is hoped that the use of the shaft valve will lead to inexpensive, reliable treatment of drinking water for those most in need.

David Billings has a degree in Biological Engineering from the University of Guelph and studied Environmental Engineering at Mohawk College. He may be reached at davidrobertbillings@yahoo.ca.

RELATED CONTENT

-

Valve Basics: Electric Actuator Controls

Electric valve actuators control the opening and closing of valves. With a motor drive that provides torque to operate the valve, these actuators are frequently used on multi-turn valves such as gate or globe and also on ball, plug and other quarter-turn valves.

-

Solenoid Valves: Direct Acting vs. Pilot-Operated

While presenting in a recent VMA Valve Basics 101 Course in Houston, I found myself in a familiar role: explaining solenoid valves (SOVs) to attendees. (I work with solenoids so much that one VMA member at that conference joked that I needed to be wearing an I Heart Solenoids t-shirt). During the hands-on “petting zoo” portion of the program, which involves smaller groups of attendees, one of the most frequently asked questions I get from people came up: What’s the difference between direct-acting and pilot-operated SOVs, and how do we make a choice?

-

Check Valves: The Most Important Valves in Your Process System

Check valves, as critical as they are for flow system performance, often don’t receive the respect they are due, said Arie Bregman, vice president and general manager, DFT, Inc., in a recent VMA presentation.

Unloading large gate valve.jpg;maxWidth=214)