Using Additive Manufacturing for Valve Repairs Across the Globe

Printing components on-site will allow for faster repairs and parts replacement for critical applications.

#gate-globe-check #components #VMAnews

Materials Can Impact Product Design Life and Produce Safer Drinking Water

Some manufacturers are investing in R&D to improve products by using new materials to extend product life and value.

#components #water-wastewater

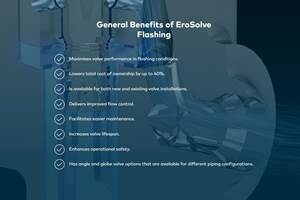

New Technology Helps to Reduce Valve Erosion From Flashing

Flashing caused by pressurized steam is a destructive phenomenon that occurs in many industries.

#components #VMAnews

Do Current Headwinds Affect the Repair or Replace Decision for Valves?

By: Heather Gaynor, Editor, Valve Magazine

Perspectives from a valve repair company and and OEM on what drives end users to make this determination.

#maintenance-repair #components

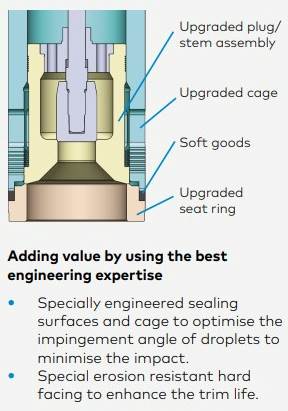

Alleviating Control Valve Erosion Critical for Uptime

Process steam leakage can affect power plant uptime.

#maintenance-repair #components

Flowserve and Chart Industries Announce Partnership to Further Enable Hydrogen Economy

Flowserve will acquire in-process R&D related to Chart’s liquid hydrogen fueling pump and will be Chart’s sole manufacturer and supplier of the pump.

#components #VMAnews

ITT Expands Compact Actuation Portfolio with Acquisition of Clippard Cylinder Product Line

ITT Inc. announced in August 2022 the acquisition of Clippard Instrument Laboratories' product lines of durable, low maintenance and cost competitive interchangeable pneumatic cylinders.

#actuators #components #VMAnews

New Surface Compact Regulator for Downstream Hydraulic Equipment

New design can be used in low- and high-pressure applications

#pressure-relief #components #VMAnews

French Fleet Awards Trillium France with Contract

The contract asks Trillium to supply equipment that requires additional qualification tests.

#components #VMAnews

New Valve for Hydrogen Fueling Stations Promotes Maintenance Safety, Minimizes Leaks

Emerson launches its TESCOM Anderson Greenwood Instrumentation H2 Valve Series for hydrogen applications.

#maintenance-repair #components

In the Air: Wireless Trends in Smart Pneumatics

In today’s wireless world it’s no surprise that automation and manufacturing spaces have embraced—and sought out—the connectivity and convenience that wireless technologies offer.

#components #automation

Biden Launches AM Forward Program to Spur Growth of 3D-printed Parts

By: Margo Ellis, Former Editor, Valve Magazine

The goal is to strengthen the manufacturing workforce and domestic supply chain through additive manufacturing (3D printing).

#components #automation

Recycling Foreign Metals: Buyer Beware

The North American steel-making industry, with its historic record of quality control, is no longer the world’s top producer.

#materials #components

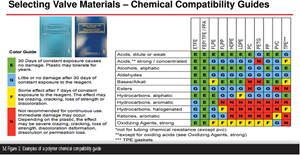

Selecting Non-metal Materials for Valve Components and Coatings

Non-metallic materials are commonly used for valve components, and the selection of non-metallic materials for valve design and for application-specific conditions is critical to ensuring product reliability.

#components #materials

Enhanced Safety in LNG Applications

For more than 40 years, the safety record of the global LNG industry has been excellent, due to attention to detail in engineering, construction and operations.

#components #knowyourvalves

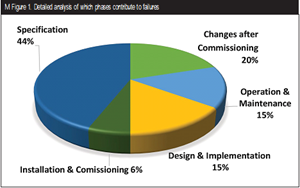

The Next Step in Functional Safety

The primary goal of functional safety is to prevent accidents.

#maintenance-repair #components #standards

Managing Valve Repair on Short Turnarounds and Downtimes

Valves are integral components in most industrial processes' overall operating efficiency, especially those in power, chemical and paper plants.

#components #maintenance-repair

Pneumatic Valves: New Technology for a Digital Transformation

Principles built around the Industrial Internet of Things have guided the automation industry’s rapid adoption and mainstreaming of many production systems.

#components #knowyourvalves #iiot

Beauty or a Beast? Using NDE on Valve Components

When it comes to valves, “beauty is only skin-deep” is often a true statement. Since Superman and his X-ray eyes don’t really exist, there is no way to verify the quality of a valve or valve component just by looking at it.

#components #maintenance-repair

Stress Wave Monitoring

Surfaces in relative motion or in contact with each other — such as bearing or gear components — produce a frequency response when they interact.

#basics #components #maintenance-repair